Introduction

Scaffolding is a critical component of any construction project, providing temporary platforms that support workers, tools, and materials at height. Selecting the right scaffolding type not only ensures safety but also improves work efficiency. Different projects call for different scaffolding systems based on height, load requirements, site layout, and specific tasks.

This guide highlights twelve widely used scaffolding types in the construction industry, outlining their key advantages.

Bamboo Scaffolding

Bamboo scaffolding is a traditional construction method that uses bamboo poles tied together to form a temporary framework. It has been widely used for centuries in Asia and is still seen in modern construction projects, especially in Hong Kong, where it is recognized for both its historical significance and structural performance.

Key Characteristics

Material: High-strength bamboo, typically harvested from fast-growing species like Bambusa.

Assembly Method: Poles are lashed using synthetic or natural ropes, often without metal connectors.

Structural Use: Suitable for vertical access, facade work, and lightweight structural support when properly engineered.

Advantages

Lightweight and Easy to Handle: Ideal for projects requiring rapid setup and dismantling.

Sustainable and Renewable: Bamboo grows quickly and has a low environmental impact.

Adaptable Design: Works well for irregular surfaces and curved architectural elements.

Cost-Efficient: Economical in regions where bamboo is locally sourced.

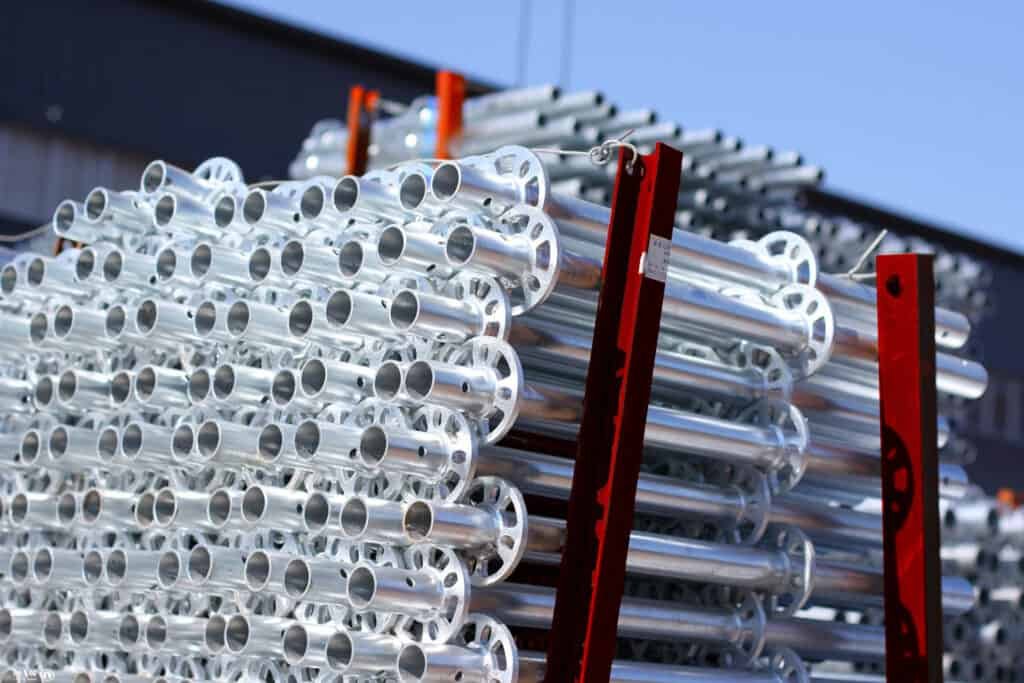

Ringlock Scaffolding

Ringlock scaffolding is a modular steel system known for its speed, versatility, and high load capacity. It uses vertical and horizontal tubes connected via rosettes (rings) that allow multiple angles, enabling fast and secure assembly.

Key Characteristics

Material: Galvanized steel tubes with integrated ring connectors.

Assembly Method: Locking wedges secure ledgers to rings without bolts.

Structural Use: Suitable for complex geometries, high-load areas, and tall structures.

Advantages

Quick and tool-free assembly.

Highly adaptable to various shapes and heights.

Durable and reusable across multiple projects.

Complies with international safety standards (EN 12810/12811, OSHA).

Fiberglass Scaffolding

Fiberglass scaffolding is a nonconductive, corrosion-resistant system used in environments where metal scaffolds pose safety risks, such as electrical or chemical zones.

Key Characteristics

Material: Glass-reinforced plastic (GRP) tubes.

Assembly Method: Modular interlocking components.

Structural Use: Electrical plants, chemical processing, and clean rooms.

Advantages

Safe for electrical and chemical environments.

Lightweight and corrosion-resistant.

Does not spark or conduct electricity.

Maintains strength in harsh conditions.

Kwikstage Scaffolding

Kwikstage scaffolding is a modular wedge-lock system designed for rapid assembly and flexibility on uneven ground. It’s widely used in commercial and civil engineering works.

Key Characteristics

Material: High-tensile steel tubes.

Assembly Method: Ledgers and transoms locked using wedge connectors.

Structural Use: Applied in both regular and irregular building layouts.

Advantages

Fast and secure wedge-lock connections.

Highly adaptable for multi-level works.

Strong load-bearing capacity.

Compatible with stair towers and deck systems.

Cuplock Scaffolding

Cuplock scaffolding is a heavy-duty modular system using a unique “cup-and-node” locking mechanism. It supports large vertical loads and is ideal for repeated, large-scale use.

Key Characteristics

Material: Steel tubes with fixed cup joints.

Assembly Method: Horizontals lock into verticals via top and bottom cups.

Structural Use: Common in bridgework, viaducts, and formwork support.

Advantages

Supports high loads with fewer components.

Speedy erection and dismantling.

Excellent for repetitive layouts and horizontal spans.

Reduces labor cost and site congestion.

Single Shoring

Single shoring is a temporary support system used to hold walls, columns, or other structures during construction, repair, or modification.

Key Characteristics

Material: Steel props, jacks, and timber or metal beams.

Assembly Method: Vertical supports braced against the structure.

Structural Use: Temporary structural stabilization or formwork support.

Advantages

Provides vital support during critical stages.

Compact and effective in confined spaces.

Adjustable to different load and height conditions.

Essential for structural retrofits.

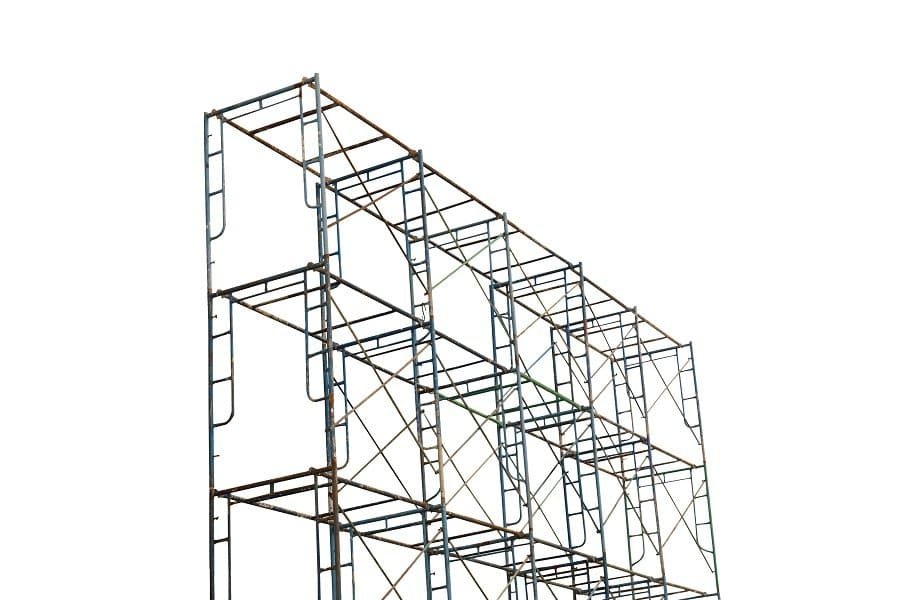

Frame Scaffolding

Frame scaffolding is a prefabricated system of steel or aluminum H-frames connected by cross braces. It’s lightweight and ideal for small to mid-scale projects.

Key Characteristics

Material: Tubular steel or aluminum.

Assembly Method: Stacked frame sections with cross-bracing.

Structural Use: Used for facade work, residential builds, and interior access.

Advantages

Simple and intuitive setup.

Cost-effective and easy to transport.

Ideal for flat-ground applications.

Quickly deployable for short-term tasks.

Climbing Scaffolding

Climbing scaffolding, or self-climbing scaffolding, uses mechanical or hydraulic systems to move vertically along a building as construction progresses.

Key Characteristics

Material: Steel platforms and frames, with motors or hydraulic lifts.

Assembly Method: Fixed to the structure and moved via control systems.

Structural Use: High-rise construction, bridge pylons, and towers.

Advantages

Saves time by eliminating disassembly/reassembly.

Improves safety with enclosed platforms.

Highly efficient for repetitive high-rise work.

Reduces labor and crane usage.

Tube & Clamp Scaffolding

Tube and clamp scaffolding is a versatile and traditional system using steel tubes connected by right-angle clamps. It allows full flexibility in design and layout.

Key Characteristics

Material: Hot-dip galvanized steel tubes.

Assembly Method: Tubes joined manually with clamps/couplers.

Structural Use: Ideal for irregular, round, or historic structures.

Advantages

Highly customizable for complex shapes.

Can be erected around obstacles or uneven ground.

Strong and durable under varied conditions.

Excellent for industrial maintenance or heritage buildings.

Mobile Scaffolding

Mobile scaffolding features platforms mounted on castor wheels, allowing for easy movement between work areas. It is commonly made from lightweight aluminum or steel.

Key Characteristics

Material: Aluminum or light steel frames.

Assembly Method: Frame sections with wheels and platform decks.

Structural Use: Maintenance, painting, and light repair work.

Advantages

Highly mobile with locking wheels.

Fast to assemble and reposition.

Ideal for interior and short-span outdoor use.

Compact and user-friendly.

Cantilever Scaffolding

Cantilever scaffolding is designed to extend horizontally from a structure when ground-level support is not possible or practical.

Key Characteristics

Material: Steel tubes and brackets.

Assembly Method: Anchored directly into the building or supported with needles.

Structural Use: Facade work above obstacles like roads or ledges.

Advantages

Maximizes access where ground clearance is limited.

Ideal for overhangs and projecting elements.

Minimizes interference with ground operations.

Allows for safe, elevated platform positioning.

Suspended Scaffolding

Suspended scaffolding is a platform hung from the top of a structure by ropes or chains. It moves vertically and is used for tasks on high-rise exteriors.

Key Characteristics

Material: Steel or aluminum platforms with suspension ropes.

Assembly Method: Hung from roof-mounted rigging systems.

Structural Use: Window cleaning, exterior painting, and inspections.

Advantages

Efficient for vertical access on tall buildings.

Minimal ground footprint.

Height-adjustable for various levels.

Quick to set up and reposition.

FAQs on Types of Scaffolding

Q: Which type of scaffolding is most commonly used?

The most widely used scaffolding systems worldwide are frame scaffolding and modular systems like Ringlock and Cuplock.

- Frame scaffolding is especially common in North America and Asia because it is lightweight, economical, and easy to assemble. It is frequently used for residential buildings, commercial sites, and renovations.

- Modular scaffolds (Ringlock and Cuplock) dominate in Europe, the Middle East, and Australia because they offer greater safety, load capacity, and flexibility, especially for industrial and infrastructure projects.

In practice, the choice often depends on regional standards, project complexity, and contractor preference.

Q: What scaffolding is best for high-rise construction?

For high-rise towers, contractors prefer Ringlock or Cuplock scaffolding systems because:

- They have high load-bearing capacity, which is essential for supporting workers, materials, and equipment at great heights.

- Multi-directional rosette (Ringlock) or cup joints (Cuplock) allow fast, safe assembly even on complex building facades.

They are compliant with EN 12810/12811 and OSHA standards, which is crucial for passing safety inspections on major projects.

Q: What is the safest type of scaffolding?

Ringlock scaffolding is generally considered the safest because:

Its rosette connection system locks components securely in multiple directions.

It provides exceptional stability and rigidity even under heavy loads.

- It includes built-in options for guardrails, toeboards, and integrated ladders, which reduce fall risks.

That said, any scaffold system — whether frame, tube-and-coupler, or Cuplock — can be safe if it is used correctly, inspected daily, and erected by trained workers. The “safest” type often depends on compliance with local standards and proper training rather than just the scaffold design.

Q: Are steel scaffolds better than wooden ones?

Yes, in most cases steel scaffolds outperform wooden scaffolds:

Strength: Steel has a much higher load-bearing capacity than timber, making it suitable for heavy-duty industrial projects.

Durability: Steel scaffolds can last 10–15 years or more, especially if hot-dip galvanized against corrosion. Wooden scaffolds degrade faster from moisture, insects, and rot.

Fire resistance: Steel is naturally fire-resistant, while wood can ignite or weaken when exposed to high temperatures.

However, wooden scaffolds are still used in some regions (e.g., bamboo scaffolding in Asia) due to cost, availability, and cultural practices. In modern regulated markets, steel or modular scaffolding is almost always preferred for compliance and safety reasons.