Introduzione

I cantieri edili sono ambienti dinamici con un elevato potenziale di pericoli, soprattutto dovuti alla caduta di oggetti. Poiché i progetti di costruzione richiedono sempre più spesso lavori in quota, la necessità di robuste misure di sicurezza diventa fondamentale. Uno di questi accessori di sicurezza essenziali è la protezione in mattoni per ponteggi. Queste barriere protettive svolgono un ruolo fondamentale nel mantenere condizioni di lavoro sicure, impedendo la caduta di detriti e materiali dalle piattaforme dei ponteggi. Questo articolo esplora le principali funzioni, tipologie e vantaggi delle protezioni in mattoni per ponteggi, evidenziando perché sono indispensabili nei cantieri moderni.

Cosa sono le protezioni in mattoni per impalcature?

Le protezioni in mattoni per impalcature sono barriere fisiche installate tra il corrimano e il fermapiede delle piattaforme di ponteggio. La loro funzione principale è impedire la caduta di attrezzi, materiali da costruzione e detriti, proteggendo così i lavoratori sottostanti e i pedoni nelle vicinanze. Questi pannelli in rete o pieni sono comunemente realizzati in filo d'acciaio, plastica o metallo e sono progettati per resistere alle sollecitazioni degli ambienti di lavoro.

Tipi di protezioni in mattoni per impalcature offerte da APAC Scaffold

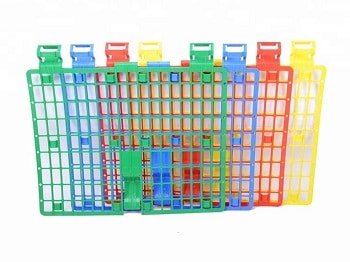

Protezioni per mattoni di plastica colorati

Disponibili in diversi colori per una facile identificazione e personalizzazione, queste protezioni sono realizzate in polipropilene antiurto modificato. Sono leggere, facili da installare e personalizzabili con il nome o il logo della vostra azienda.

Protezioni per mattoni in plastica rinforzata

Presentano una solida struttura integrata con fori di rinforzo e morsetti fermapiede integrati. La loro maggiore stabilità li rende ideali per applicazioni ad alto traffico o vento forte.

Protezioni in mattoni metallici

Queste robuste opzioni si agganciano saldamente al corrimano, chiudendo lo spazio tra la piattaforma e il parapetto. Ideali per installazioni di ponteggi permanenti o a lungo termine.

Perché le protezioni in mattoni per impalcature sono importanti

1. Prevenire la caduta di oggetti

La caduta di oggetti è una delle principali cause di infortuni nei cantieri edili. Le protezioni in mattoni fungono da rete di sicurezza che trattiene i materiali incoerenti sulle piattaforme elevate. La loro installazione riduce significativamente il rischio di incidenti causati dalla caduta di utensili o dallo spostamento di detriti.

2. Migliorare la sicurezza dei lavoratori

Le protezioni in mattoni garantiscono la massima tranquillità ai lavoratori che operano in quota. Fissando i materiali all'interno dell'area della piattaforma, queste protezioni creano un ambiente più sicuro e controllato, soprattutto in condizioni meteorologiche ventose o imprevedibili.

3. Conformità alle normative in materia di salute e sicurezza

In molti paesi, tra cui Regno Unito e Australia, i cantieri edili devono rispettare rigide normative di sicurezza, come le normative sul lavoro in quota e gli standard OSHA. Le protezioni in mattoni contribuiscono a garantire il rispetto delle norme, fornendo una barriera fisica che previene gli incidenti dovuti alla caduta di oggetti.

4. Durevole e duraturo

Le protezioni in mattoni di alta qualità, realizzate con materiali come l'acciaio zincato o la plastica antiurto, sono progettate per durare a lungo. Possono resistere a condizioni ambientali difficili, resistere alla corrosione e possono essere riutilizzate in più progetti, riducendo i costi delle attrezzature di sicurezza a lungo termine.

Caratteristiche uniche delle protezioni in mattoni

- Design innovativo: Le clip integrate nella pedana mantengono la protezione saldamente in posizione.

- Nessun gancio aggiuntivo necessario: Il design aerodinamico e integrato del gancio previene la perdita e semplifica l'installazione.

- Resistente al vento: Speciali meccanismi di bloccaggio garantiscono la stabilità anche in condizioni meteorologiche avverse.

- Facile stoccaggio e trasporto: I design anti-groviglio e impilabili semplificano la logistica e ne riducono i costi.

Applicazioni nei sistemi di ponteggi

Le protezioni in mattoni sono compatibili con tutti i principali tipi di ponteggi, tra cui:

Che operiate in ambienti urbani, nello sviluppo di infrastrutture o nella costruzione di grattacieli, le soluzioni APAC garantiscono la protezione e la conformità del sito del vostro progetto.

Riepilogo: perché hai bisogno di protezioni per mattoni

Le protezioni in mattoni sono parte integrante dei sistemi di sicurezza per ponteggi. Proteggono i lavoratori, prevengono gli incidenti e contribuiscono a garantire la conformità alle normative. Grazie alla vasta gamma di protezioni in mattoni personalizzabili e resistenti di APAC Scaffold, gli appaltatori di tutto il mondo possono migliorare la sicurezza mantenendo l'efficienza operativa.

Domande frequenti

Qual è il materiale migliore per le protezioni in mattoni delle impalcature?

Il filo di acciaio e la plastica antiurto sono i materiali più comuni ed efficaci, in quanto offrono un equilibrio tra resistenza, durevolezza e flessibilità.

Le protezioni in mattoni possono essere riutilizzate?

Sì, le protezioni in mattoni di alta qualità di APAC Scaffold sono costruite per durare e possono essere riutilizzate in più progetti.

Le protezioni in mattoni sono obbligatorie su tutte le impalcature?

Sebbene le normative varino da Paese a Paese, la maggior parte degli standard di sicurezza raccomanda o richiede l'uso di protezioni in mattoni per impedire la caduta di oggetti nelle zone di lavoro elevate.

Come vengono imballate le protezioni in mattoni della regione APAC per la spedizione?

Sono confezionati in vassoi di acciaio per un trasporto sicuro ed efficiente e sono progettati per essere anti-groviglio e impilabili.

Posso far stampare il logo della mia azienda sulle protezioni in mattoni?

Sì, APAC offre la personalizzazione con loghi, colori e dimensioni stampati o stampati per soddisfare le vostre esigenze operative e di branding.