ملحقات القوالب

- توفير شامل: الإكسسوارات + العوارض + الخشب الرقائقي

- دعم الاختيار: مطابقة الأجزاء مع نظام القوالب الخاص بك (Doka/Peri/Euro/Aluminium)

- أسعار المصنع مباشرة للطلبات المتكررة (تحكم أفضل في التكاليف للموزعين والمقاولين)

- وثائق الجودة والاختبار الجاهزة للتدقيق (تتوفر تقارير اختبار المواد وتقارير الاختبار)

ما هي ملحقات القوالب الخشبية؟

ملحقات القوالب هي قطع ومكونات معدنية تُستخدم لتوصيل القوالب ومحاذاتها وتثبيتها ودعمها أثناء صب الخرسانة، مما يضمن بقاء القالب في الوضع والشكل الصحيحين حتى تكتسب الخرسانة قوتها. تشمل هذه الملحقات عناصر مثل قضبان الربط، والصواميل، والصواميل المجنحة، وصفائح التثبيت، والمشابك، والأوتاد/الدبابيس، وسدادات المياه، والأقماع/الأكمام، ومثبتات العوارض، وهي ضرورية للسلامة والدقة وسرعة التركيب/الفك في الموقع.

أنواع ملحقات القوالب

مصنوعة من فولاذ عالي القوة، أو حديد مطّاط، أو بلاستيك هندسي متين، وملحقاتنا متوافقة مع قوالب الأخشاب التقليدية، بالإضافة إلى أنظمة الوحدات الرائدة. بفضل رقابة الجودة الصارمة، والأحجام الموحدة، والتشطيبات المقاومة للتآكل، توفر ملحقات قوالب APAC أداءً موثوقًا به على مدار دورات البناء المتكررة.

سواء كنت مقاولاً أو موزعًا أو شركة تأجير، توفر APAC خيارات OEM/ODM مرنة وأسعارًا تنافسية وإمدادات متسقة لتلبية متطلبات مشروعك.

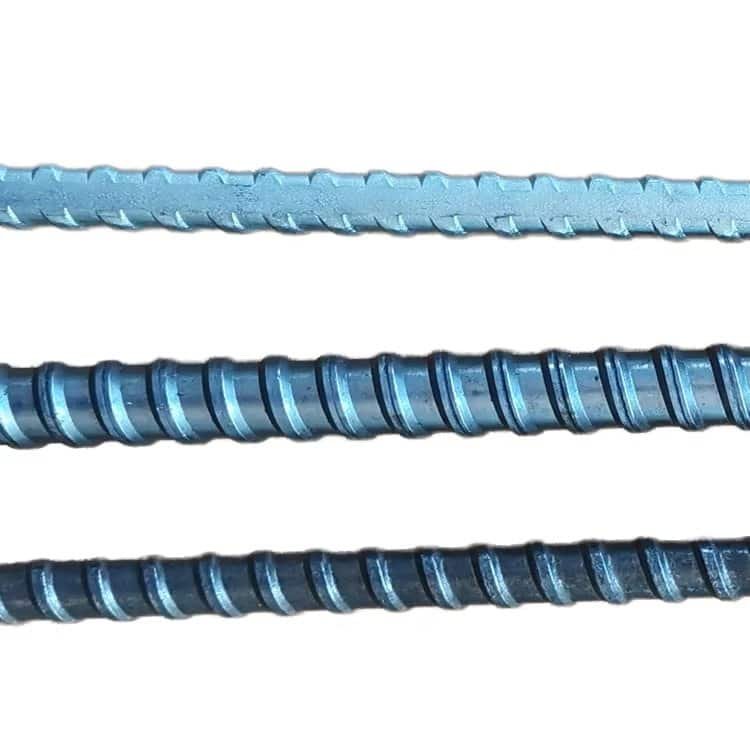

قضيب الربط (قضيب ربط القوالب)

قضيب فولاذي عالي الشد يربط ألواح القوالب المتقابلة؛ يقاوم ضغط الخرسانة؛ متوفر بقطر 15/17 مم.

صفيحة والر / صفيحة المحمل

يقوم بتوزيع حمل قضيب الربط على مساحة أكبر؛ ويحمي لوحة القوالب من التشوه.

صامولة الجناح / صامولة المرساة

يعمل مع قضبان الربط لتشديد وربط الألواح؛ فولاذ مزور؛ متوفر مع لوحة والير أو شفة ثابتة.

مخروط بلاستيكي / فاصل

يحافظ على سمك الجدار ويضمن التباعد الثابت؛ من النوع القابل للإزالة أو الانفصال؛ يستخدم مع قضبان الربط.

صامولة مانعة لتسرب الماء

يمنع التسرب من خلال فتحات الربط في الهياكل التي تحتفظ بالمياه؛ الجسم المصنوع من الحديد الزهر أو الحديد المطاوع.

مشبك إسفين سريع

موصل سريع الفك لتثبيت الجنود أو المشاة أو الألواح؛ مما يسرع عملية التجميع والتفكيك.

مجموعة مسامير على شكل حرف T وصامولة جناح

جهاز تثبيت لتأمين ملحقات القوالب؛ متوفر بأطوال وخيوط مختلفة.

دبوس وإسفين القوالب

قفل مفاصل اللوحة أو محاذاة؛ اتصال مطرقة بسيط؛ مثالي لقوالب الأعمدة والعوارض.

مشبك عمود قابل للتعديل

يثبت ويحكم قوالب الأعمدة المستطيلة بدون قضبان ربط؛ هيكل فولاذي؛ طول قابل للتعديل؛ تجميع سريع.

مشابك محاذاة القوالب

يقوم بمحاذاة وربط لوحين متجاورين من القوالب للحفاظ على خطوط الوصل المستقيمة؛ يوفر إحكامًا سريعًا بنظام الإسفين أو المسمار؛ يحسن تسطيح الجدار الخرساني.

مشابك إغلاق قابلة للتعديل

مشبك متعدد الاستخدامات للألواح الخشبية/الفولاذية؛ يحل محل قضبان الربط في بعض التطبيقات؛ مثالي للتركيب السريع حول العوارض والألواح والجدران. هيكل فولاذي بتصميم انزلاقي قابل للتعديل.

مشابك أعمدة الخرسانة شبه

متوافق مع قوالب الأعمدة PERI؛ يطبق قوة تثبيت عالية للحفاظ على ألواح الأعمدة محكمة تحت ضغط الخرسانة الطازجة؛ مجلفن بالغمس الساخن لضمان عمر خدمة طويل.

مشبك عمود قابل للتعديل

دعم عمودي تحت الألواح أو العوارض، ارتفاع قابل للتعديل، قدرة تحمل تصل إلى 30 كيلو نيوتن.

حامل ثلاثي القوائم قابل للتعديل

يحافظ على استقرار الدعائم قبل صب الخرسانة؛ طبقة نهائية مجلفنة لمقاومة التآكل.

رأس جاك / رأس شوكة U-Head

يناسب الجزء العلوي من الدعامات لحمل عوارض H أو العوارض الأساسية؛ تعديل المسمار للتسوية.

مقبس القاعدة / لوحة القاعدة القابلة للتعديل

يدعم الدعائم أو المعايير على الأسطح غير المستوية؛ ويوفر إمكانية تعديل الارتفاع والاستقرار.

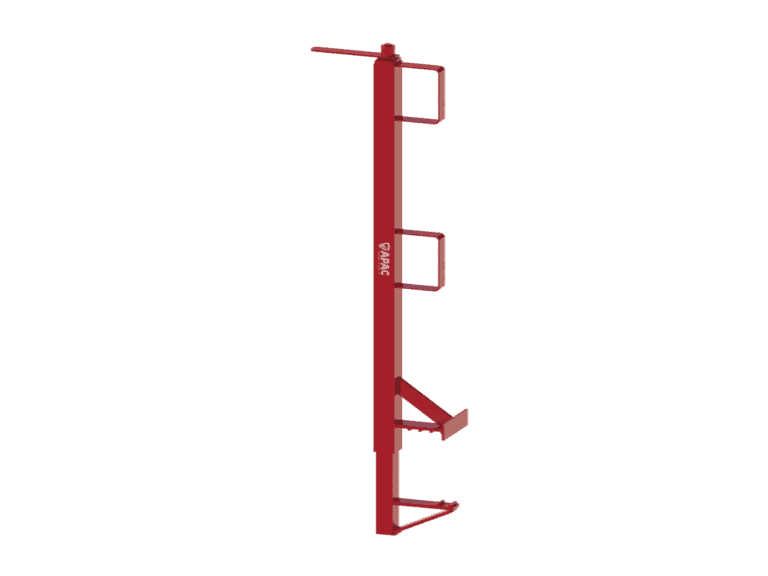

دعامة دفع وسحب (دعامة قابلة للتعديل)

يقوم بمحاذاة وتقويم قوالب الحائط أو العمود؛ يمكن تعديل الطول باستخدام مشبك شد.

مشبك الربط / دعامة الأنابيب

يستخدم لمحاذاة قوالب الجدران أو الأعمدة بشكل دقيق، وضبط التوتر بسهولة.

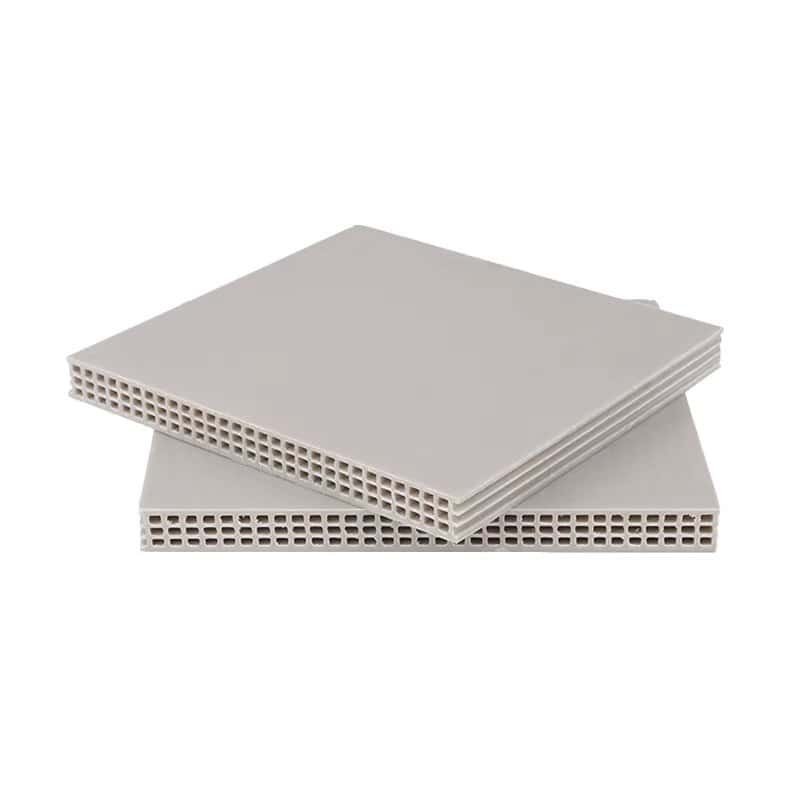

لوحة القوالب البلاستيكية

خفيف الوزن وخالٍ من التآكل؛ مثالي للتجميع السريع ودورات إعادة الاستخدام العالية.

لوحة قالب الخشب الرقائقي

سطح مغطى بطبقة من الفيلم أو مطلي بالفينول للحصول على لمسة نهائية ناعمة للخرسانة؛ يمكن إعادة استخدامه من 5 إلى 10 مرات.

لماذا تختار ملحقات قوالب APAC؟

ملحقات القوالب الخرسانية قطع صغيرة ذات تأثير كبير: المحاذاة، والتحكم في التسرب، وثبات الصب، وكفاءة الفك. صُممت مجموعتنا لمساعدة فرق المشتريات وفرق العمل في المواقع على الحصول على قطع غيار متوافقة بسرعة أكبر، وتقليل المكونات غير المتطابقة، والحفاظ على سير أعمال صب الخرسانة بسلاسة.

توفير شامل لأنظمة قضبان الربط، والمشابك، والعوارض، والخشب الرقائقي

بدلاً من تقسيم طلبات عروض الأسعار بين موردين متعددين، يمكنك توحيد المواد الاستهلاكية الرئيسية وعناصر الطلب المتكرر في مكان واحد.

مكونات نظام قضبان الربط: قضبان الربط، والصواميل المجنحة/صواميل التثبيت، وصفائح التثبيت، وسدادات المياه، والأكمام والمخاريط

المشابك والوصلات: مشابك قفل إسفينية، مشابك محاذاة، مشابك زنبركية/مشابك سريعة، مشابك تيكو، مشابك تثبيت القوالب

عوارض وألواح القوالب: عوارض H20، عوارض ألومينا، خشب رقائقي مغطى بغشاء رقيق

توافق نظام القوالب

نقوم بتنظيم المنتجات وفقًا لأنظمة المواقع الحقيقية، حتى تقضي وقتًا أقل في التحقق من توافق الأجزاء معًا.

ملحقات نظام يورو فورم (دبابيس، أسافين، روابط، خطافات، قطاعات)

ملحقات قوالب الألمنيوم (الأوتاد/الدبابيس، والعوارض الخشبية، والأجزاء ذات الصلة كما هو موضح)

مشابك من نوع دوكا وبيري وخيارات المشابك ذات الصلة

مراقبة الجودة ودعم التوثيق للموافقات

عندما تتطلب المشاريع إمكانية التتبع والإثبات، فإننا نشير إلى ضوابط مراقبة الجودة ونقدم الملفات الداعمة المذكورة في محتوى الصفحة.

مراقبة جودة التصنيع وفقًا لمعيار ISO 9001 (كما هو مذكور)

فحص نموذج أولي للتأكد من التوافق (أذرع الربط، والصواميل، وتركيب الملحقات)

تتوفر تقارير اختبار MTC والاختبارات للطلبات

موثوق به من قبل المقاولين في جميع أنحاء العالم

التطبيقات

تضمن الملحقات المتينة محاذاة دقيقة، وكفاءة تجميع محسّنة، وظروف عمل أكثر أمانًا، وجودة خرسانة ثابتة - حتى في ظل ظروف الموقع الصعبة. تُستخدم ملحقات قوالب APAC على نطاق واسع في:

الجدران الأساسية وجدران القص للمباني الشاهقة

بناء بلاطات سكنية وتجارية

أرصفة الجسور والبنية التحتية للطرق السريعة

الأعمدة والعوارض الصناعية

هياكل الاحتفاظ بجدار الطابق السفلي

الأنفاق وخزانات الاحتفاظ بالمياه

أنظمة القوالب الجاهزة والوحدات النمطية

ملحقات القوالب | الأسئلة الشائعة

1. هل ملحقات قوالب الخرسانة من شركة APAC متوافقة مع العلامات التجارية الأخرى؟

نعم. تتوافق أنظمة تحديد المقاسات وقطر الخيوط والتوصيل لدينا مع معايير الصناعة الشائعة، بما في ذلك PERI وDoka وSateco وMeva وأنظمة القوالب التقليدية.

2. ما هي المعالجات السطحية المتاحة؟

نقدم خدمات الجلفنة بالغمس الساخن، والجلفنة الكهربائية، والطلاء بالمسحوق. يمكن اختيار معالجة السطح بناءً على المناخ، ومخاطر التآكل، ومدة المشروع.

3. هل يمكنني تخصيص الأبعاد أو مواصفات الخيوط؟

بالتأكيد. ندعم تخصيص OEM/ODM، بما في ذلك الطول، ودرجة الصوت، ونمط الرأس، والعلامة التجارية. لا تتردد في طلب الرسومات أو العينات.

4. كم مرة يمكن إعادة استخدام الملحقات؟

بالتأكيد. ندعم تخصيص OEM/ODM، بما في ذلك الطول، ودرجة الصوت، ونمط الرأس، والعلامة التجارية. لا تتردد في طلب الرسومات أو العينات.

5. هل تقدمون تقارير أو شهادات فحص؟

نعم. يمكننا تقديم شهادات المواد، ونتائج اختبارات الشد، وتقارير سُمك الطلاء السطحي، وشهادات مطابقة المواد عند الطلب.

6. ما هو وقت التسليم المعتاد لديكم؟

يتم شحن المنتجات القياسية خلال 15 إلى 30 يومًا اعتمادًا على حجم الطلب ومتطلبات التخصيص.

7. هل توفرون الملحقات كحزم كاملة؟

نعم. يمكننا تجميع قضبان الربط، والصواميل، والألواح، والأقماع في مجموعات تغليف للموزعين أو شركات التأجير.