Tablones de andamio LVL

- Probado y certificado para cumplir con los requisitos de seguridad de OSHA y ANSI.

- Producción automatizada + control de calidad estricto para lotes repetibles: mejor para el suministro de múltiples proyectos.

- Fabricado con pegamento fenólico WBP de grado A, hervido a 100 °C durante 72 horas sin delaminación, diseñado para exposición en sitios hostiles.

- 10% más liviano que la madera maciza, menor costo de manipulación, instalación/desmontaje más rápido, mayor productividad diaria para las tripulaciones y los plazos de entrega de alquileres.

¿Qué son los tablones de andamio nivelados?

El tablón de andamio LVL (madera laminada enchapada) es un tablón de andamio LVL liviano y de alta resistencia que se usa ampliamente en toda la industria de la construcción.

El tablón de andamio LVL es superior, ligero y fiable. Cada tablón se somete a rigurosos controles de calidad y pruebas según las normas AS/NZS, lo que garantiza una resistencia y seguridad inigualables.

Tipos de tablones de andamios

Disponemos de una amplia gama de tablones para andamios LVL, en diversos tamaños y calidades, para satisfacer las diversas necesidades de nuestros clientes. Nuestra dedicación a la calidad y la satisfacción del cliente nos ha convertido en un socio de confianza para empresas de todo el mundo.

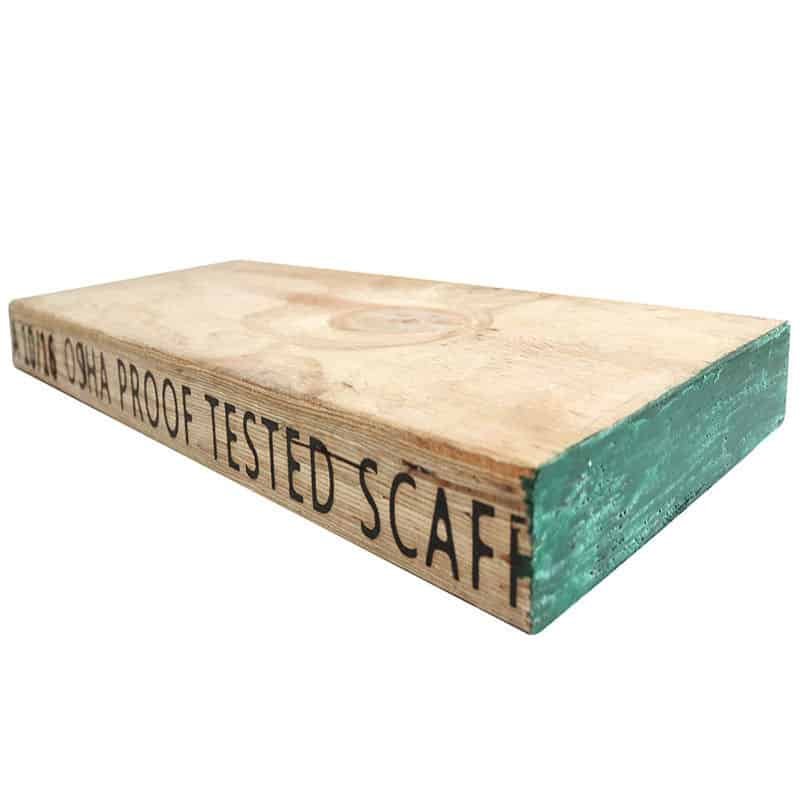

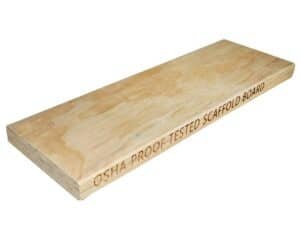

Tablón de andamio de nivel sin pintar

El modelo básico de tablón, que cumple con los requisitos estándar.

- MOQ: 17 metros cúbicos

Tablón de andamio de nivel con pintura

Colores llamativos personalizables, más adecuados para uso en el lugar de trabajo.

- MOQ: 17 metros cúbicos

Tablón de andamio de nivel con extremo mental

Fije el borde de los tablones LVL para evitar que la tabla se parta.

- MOQ: 17 metros cúbicos

Tableros de andamios LVL: una solución duradera y segura para la construcción

Las tablas de andamios de madera son esenciales durante la construcción, ya que proporcionan una plataforma sobre la que los trabajadores pueden pararse mientras trabajan en altura.

- 10% Más ligero que la madera maciza.

- 100% Abeto y pino sostenibles y de calidad.

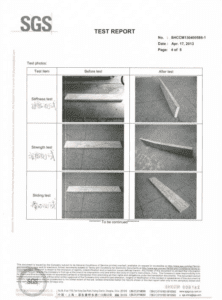

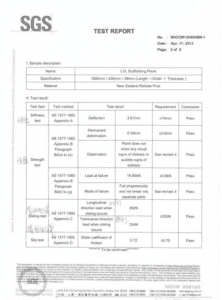

- Prueba individual Prueba Informe por SGS.

- Fuerte, ligero y confiable en comparación con la madera convencional.

- Excelente resistencia a la corrosión y a los productos químicos.

- Personalizar Tamaños que se adaptan perfectamente a su andamio.

- Varias opciones para el sello final.

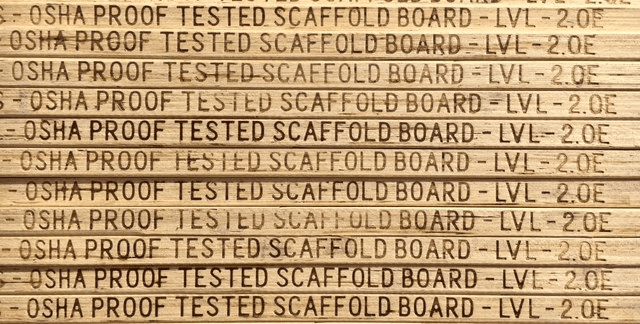

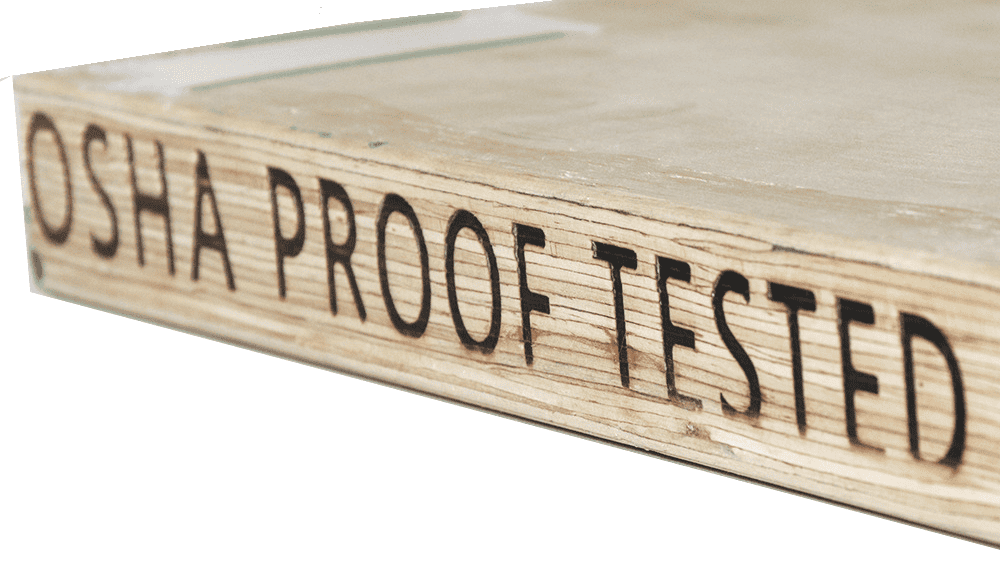

- Fecha de producción y logotipo de la empresa grabados en relieve.

APAC es un fabricante y proveedor con muchos años de experiencia en la exportación de grandes cantidades de tablones LVL en Porcelana.

Tenemos una sólida reputación en la industria por producir tablones de andamios de alta calidad que cumplen con las normas internacionales. OSHA Normas.

Nuestro equipo está comprometido a brindar el mejor servicio posible a nuestros clientes y garantizar que cada pedido se cumpla a su satisfacción.

¿Por qué elegir la plataforma APAC lvl?

Los tablones LVL de APAC están diseñados para brindarle un rendimiento de plataforma repetible, un control del sitio más fácil y un menor costo del ciclo de vida en trabajos repetidos.

Tablones de andamio directos de fábrica

Somos fabricantes directos de fábrica, por lo que nos enorgullecemos de ofrecer tablones de madera de alta calidad a precios competitivos.

Nuestro proceso de producción incluye el uso de maquinaria de última generación totalmente automatizada. Esto nos permite producir productos que cumplen y superan los estándares de la industria con precisión y consistencia. Nos enorgullecemos de brindarles a nuestros clientes tablones confiables y duraderos.

Tablones LVL certificados

Los tablones de andamios LVL están probados y certificados para cumplir con estrictos estándares de seguridad, como OSHA y Normas americanas, lo que garantiza que puedan soportar los rigores de las obras de construcción.

Los tablones también están tratados con una superficie antideslizante para evitar que los trabajadores resbalen y caigan mientras trabajan en altura.

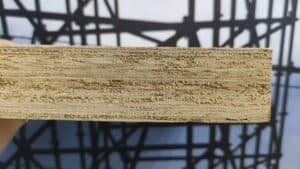

Pegamento fenólico WBP / resistente al agua

Los tablones de andamio LVL están hechos de capas delgadas de chapas de madera que se pegan entre sí con un adhesivo fuerte. Este proceso crea un tablón fuerte y estable que es resistente a la deformación, la torsión y el agrietamiento.

Nuestros tablones para andamios LVL se fabrican con pegamento fenólico WBP de grado “A”. Los tablones se han probado y hervido en agua caliente a 100 grados durante 72 horas sin delaminación.

Control de calidad estricto

Para garantizar la calidad, los tablones para andamios APAC LVL se producen bajo un estricto control de calidad y certificación de producto. La madera que utilizamos se importa legalmente de Nueva Zelanda.

Nuestras tablas han sido sometidas a pruebas de resistencia a la flexión, capacidad de carga vertical y resistencia a la humedad para garantizar que cumplen o superan los estándares de la industria. Puede confiar en que nuestras tablas LVL brindarán un soporte confiable y duradero para su proyecto de construcción o renovación.

Embalaje

Cuando se trata de embalaje, nuestros servicios de transporte son confiables y eficientes, y utilizamos solo los mejores transportistas para transportar sus productos a su destino.

Además, ofrecemos opciones de embalaje personalizadas para satisfacer sus necesidades y requisitos específicos.

- Embalado en palets, envuelto en plástico y reforzado con correas de hierro.

- Según requerimientos.

Con la confianza de contratistas de todo el mundo

Aplicaciones de los tablones de andamio nivelados

Los tablones de andamios LVL se utilizan como plataformas de trabajo en una amplia variedad de configuraciones de andamios en todo el mundo, proporcionando una plataforma estable para los oficios durante el trabajo de fachada, albañilería, pintura, instalación MEP y acceso general.

En la práctica, un tablón de andamio LVL se instala con mayor frecuencia en cerradura de anillo, cuplock, andamios de marco, o travesaños de tubo y abrazadera para crear pasarelas, zonas de carga/aterrizaje y plataformas continuas a lo largo de las elevaciones de los edificios.

Tablones de andamio LVL | Guía completa de preguntas frecuentes

1. ¿Cuáles son los requisitos de OSHA para los tablones de andamios?

OSHA no exige un “tipo de tablón” específico, pero hace requerir el plataforma y sus componentes (incluidos los tablones) para que sean seguros para la carga y la instalación previstas. Los requisitos clave para el entablado incluyen:

Capacidad (factor de seguridad 4:1): Los componentes del andamio deben soportar su propio peso + al menos 4 veces la carga máxima prevista.

Límite de deflexión: plataformas no debe desviarse más de 1/60 del tramo cuando está cargado.

Guía de selección/identificación: El Apéndice A de OSHA (no obligatorio) proporciona tablas de longitud y señala que los tablones aserrados de manera sólida deben seleccionarse según las reglas de clasificación de madera reconocidas e identificarse mediante un sello de clasificación.

2. ¿Cuál es el propósito de un tablón de andamio?

La función de un tablón de andamio es crear una plataforma de trabajo segura y continua—apoyar a los trabajadores, las herramientas y los materiales en altura—mientras mantiene la capacidad requerida y limita la deflexión bajo carga (para que la plataforma permanezca estable).

3. ¿Cuál es la mejor madera para los tablones de andamios?

A nivel mundial, “mejor” tiene menos que ver con las especies y más con rendimiento calificado + clasificación/trazabilidad. En los EE. UU., OSHA enfatiza la selección de tablones utilizando reglas de clasificación reconocidas (guía del Apéndice A).

Prácticamente:

América del norte: Los tablones de andamio son comunes maderas blandas clasificadas (por ejemplo, el pino amarillo del sur se usa ampliamente), pero la clave es la tabla de grados/clasificaciones y alcances, no sólo la especie.

UE/Reino Unido: Los tableros de andamios de madera suelen cumplir con los estándares locales (por ejemplo, UK BS 2482 para tableros de madera), lo que enfatiza nuevamente Dimensiones y clasificación definidas.

4. ¿Qué grosor debe tener un tablón de andamio?

Depende del mercado/estándar en el que estés trabajando:

Norma BS 2482:2009 del Reino Unido (tableros de andamios de madera): especifica 225 mm de ancho y 38 mm o 63 mm de espesor.

OSHA (EE. UU.): OSHA se centra en la capacidad/deflexión y proporciona una guía sobre la longitud en el Apéndice A (por ejemplo, tablas para tablones sólidos aserrados nominales de 2×10), en lugar de un único “espesor” obligatorio.”

5. ¿Cuándo no se deben utilizar tablones de andamio?

Hacer no Utilice tablones que sean defectuoso, dañado o debilitado de tal manera que creen un peligro. OSHA requiere que los componentes de andamios dañados o debilitados sean reparado/reemplazado (con la supervisión de una persona competente), y OSHA ha aclarado que un defecto como una división no descalifica automáticamente. si No crea ningún peligro y la tabla aún cumple con los requisitos de carga.

Los desencadenantes prácticos de “retirada del servicio” generalmente incluyen: grietas graves, puntos podridos o blandos, delaminación (tablones diseñados), extremos aplastados, hendiduras profundas o daños que afectan las áreas de apoyo o el contacto de soporte.

6. ¿Cómo hacer que los tableros de andamios sean impermeables?

Generalmente No debería "hacerlo usted mismo a prueba de agua"“ una tabla de una manera que cambia su clasificación o la hace resbaladiza: siga las fabricante y su práctica local de cumplimiento. Medidas prácticas y ampliamente utilizadas son:

Almacenamiento y manipulación: mantener tablas fuera del suelo, seco y fuera del agua estancada; un buen almacenamiento es a menudo el factor más importante en la vida útil.

Sellado/protección de extremos: usar bandas/tapas de extremo y asegúrese de que los extremos estén sellados (los extremos son donde a menudo comienza el daño por humedad).

Recubrimientos de fábrica (preferibles): Si necesita resistencia al agua, especifique las tablas/tablones suministrados con revestimiento/sellado de bordes aprobado y rendimiento documentado: evite recubrimientos aplicados en el lugar que reducen la resistencia al deslizamiento.