Qu'est-ce qu'un échafaudage Ringlock ?

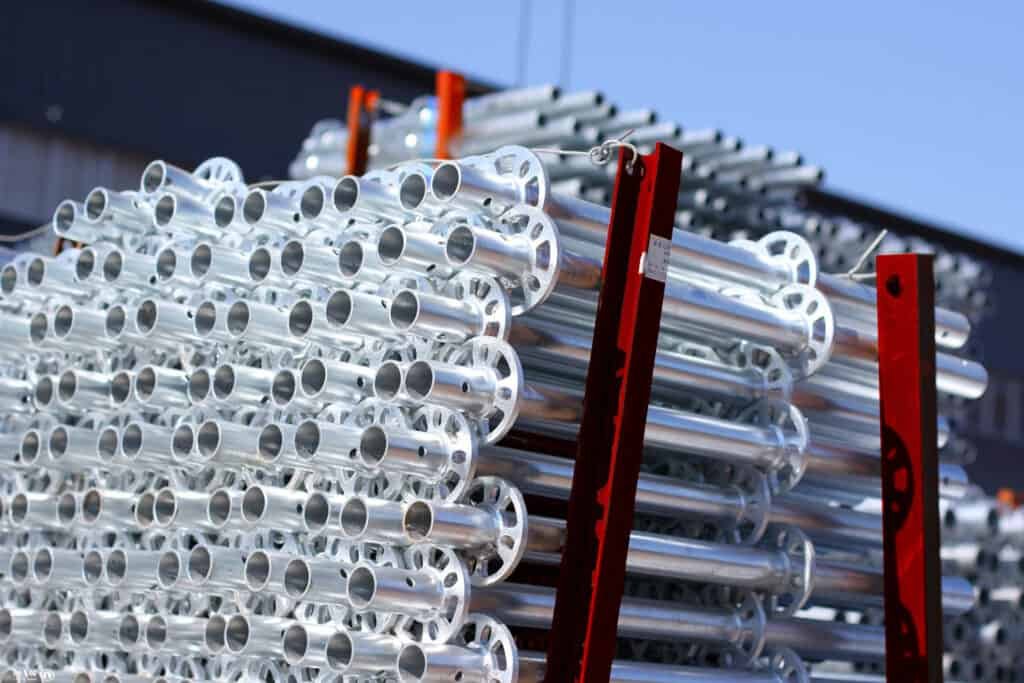

L'échafaudage Ringlock est un système modulaire polyvalent conçu pour un assemblage efficace et rapide. Il utilise un connecteur à rosace pour relier les éléments horizontaux, verticaux et diagonaux selon différents angles. Contrairement aux échafaudages traditionnels à tubes et raccords, qui reposent sur des boulons et des colliers, Ringlock utilise un système à clavettes et rosaces, plus rapide, plus sûr et plus fiable. Ce système s'adapte facilement à différentes formes et hauteurs de bâtiments, ce qui le rend idéal pour les structures simples comme complexes.

Concept de base :

Les standards (verticaux) ont des rosaces soudées à intervalles fixes.

Les grands livres (horizontaux) et les supports se connectent à la rosace avec des têtes de coin.

Un marteau fixe la cale — aucun boulon, écrou ou clé n’est requis.

Bref historique :

Développé à la fin du 20e siècle comme une amélioration des systèmes Cuplock et tube-et-coupleur.

Conçu pour accélérer le montage, augmenter la sécurité et réduire la complexité des composants.

Popularité mondiale :

Largement adopté en Europe, au Moyen-Orient, en Amérique du Nord et en Asie-Pacifique.

Privilégié dans les industries où les projets sont de grande envergure, complexes et urgents.

Caractéristiques principales

Connecteur à rosace

- Permet jusqu'à 8 connexions à différents angles.

- Permet de réaliser des échafaudages complexes et multidirectionnels (idéal pour ponts, réservoirs, façades courbes).

Conception modulaire

- Normes, grands livres, traverses et contreventements préfabriqués.

- Les composants standardisés simplifient la logistique et l’assemblage.

Assemblage sans outil

- Système de coin et de marteau.

- Aucun écrou, boulon ou clé requis, ce qui réduit les pièces perdues et accélère le travail.

Capacité de charge élevée

- Conçu pour les projets lourds avec des charges de travail sûres (SWL) testées selon les normes EN 12810/12811 et OSHA 1926.451.

Versatilité

Fonctionne pour les structures droites, circulaires, inclinées ou irrégulières.

Également efficace pour les échafaudages de façade, les tours d'étaiement ou les échafaudages suspendus.

Quels sont les avantages des échafaudages Ringlock ?

L'échafaudage Ringlock offre plusieurs avantages clés qui en font un choix populaire pour les projets de construction :

Avantage | Explication |

Facile à assembler | Moins de composants le rendent plus rapide et plus simple à assembler par rapport aux autres systèmes d'échafaudage. |

Capacité de charge élevée | Assez solide pour supporter des matériaux et équipements lourds, réduisant ainsi le besoin de structures de support supplémentaires. |

Flexibilité | Adaptable aux grands et petits projets de construction, permettant des modifications de hauteur et de structure. |

Rentabilité | Moins de pièces signifie des coûts globaux inférieurs, tant en termes de matériaux que de main-d'œuvre. |

Durabilité | La finition galvanisée à chaud résiste à la rouille et à la corrosion, ce qui la rend adaptée à une utilisation à long terme, en particulier à l'extérieur. |

Quel est le matériau de l'échafaudage Ringlock ?

Les échafaudages Ringlock sont principalement fabriqués à partir de acier, généralement Acier Q355, qui est à la fois solide et durable. Il est souvent recouvert de galvanisation à chaud pour le protéger de la corrosion, garantissant une utilisation à long terme même dans des conditions climatiques difficiles. L'acier est le matériau de choix pour les échafaudages en raison de son rapport résistance/poids, offrant à la fois stabilité et facilité de manipulation.

Acier | Solide, porteur et facilement soudable ou fabriqué pour différentes configurations. |

Acier galvanisé | Résiste à la corrosion, ce qui le rend idéal pour les environnements extérieurs et très humides. |

Aluminium | Alternative légère — jusqu'à 30% plus léger que l'acier. |

Finitions de surface

Galvanisation à chaud:Assure une longue durée de vie et une résistance à la rouille, notamment dans les environnements côtiers ou industriels.

Revêtement en poudre:Ajoute des options de marquage et une protection supplémentaire contre la corrosion.

Quelles sont les tailles des échafaudages Ringlock ?

Les composants d'échafaudage Ringlock sont disponibles dans une variété de tailles pour s'adapter à différentes hauteurs et types de bâtiments. longueurs de poteaux verticaux vont de 1,5 mètre à 3 mètres, alors que croisillons horizontaux peut varier en fonction de la portée requise pour chaque projet.

Taille | Longueur | Cas d'utilisation |

Standard | 1,5 m, 2,0 m | Le plus courant, adapté aux structures de taille moyenne. |

Étendu | 2,5 m, 3,0 m | Utilisé pour les bâtiments plus hauts ou les plates-formes plus grandes. |

Horizontal | Varie | Les entretoises horizontales relient les poteaux verticaux et assurent la stabilité. |

Quel est le diamètre d'un échafaudage Ringlock ?

Le diamètre des poteaux verticaux dans les échafaudages à anneau sont généralement 48,3 mm, qui est la taille standard de la plupart des systèmes d'échafaudages. Cette taille offre un juste équilibre entre résistance et facilité de manipulation, garantissant que l'échafaudage peut supporter des charges importantes tout en restant facile à gérer.

Composant | Diamètre | Cas d'utilisation |

Poteaux verticaux | 48,3 mm | Taille standard pour la plupart des applications de construction. |

Mécanisme de verrouillage | 48,3 mm | Diamètre constant pour un assemblage facile et une stabilité optimale. |

À quoi sert un anneau de verrouillage ?

Le anneau de verrouillage est l'élément central du système, utilisé pour relier les poteaux verticaux et les supports horizontaux. Il garantit que les composants restent en place, formant une plate-forme sûre et stable. Le mécanisme de verrouillage permet un montage et un démontage rapides, ce qui le rend idéal pour les projets qui nécessitent flexibilité et rapidité.

Composant | Fonction |

Anneau de verrouillage | Fixe ensemble les poteaux verticaux et les supports horizontaux, formant ainsi une structure stable et fiable. |

Poteaux verticaux | Fournit le support de charge principal pour le système d’échafaudage. |

Applications des échafaudages Ringlock

Les échafaudages Ringlock sont utilisés dans une large gamme d'applications dans le secteur de la construction, des bâtiments résidentiels aux projets industriels à grande échelle. Certaines applications courantes incluent :

- Construction de bâtiments:Idéal pour les petits et les grands bâtiments, y compris les projets à plusieurs étages.

- Ponts et viaducs:Utilisé pour les échafaudages sur des infrastructures à grande échelle comme les ponts et les viaducs autoroutiers.

- Mise en scène d'événements:Utilisé dans la construction de scènes temporaires pour des événements en plein air et des concerts.

- Entretien:Parfait pour une utilisation dans les projets de maintenance et de réparation industriels, en particulier dans les endroits difficiles d'accès.

Catalogue d'échafaudages Ringlock

Vous recherchez un aperçu détaillé de tous les composants et spécifications de Échafaudage Ringlock? Téléchargez notre Catalogue d'échafaudages Ringlock Accédez dès maintenant à des informations complètes sur toutes les tailles, composants et détails techniques disponibles. Ce catalogue vous aidera à choisir les bons matériaux pour votre prochain projet et vous assurera de disposer de tout ce dont vous avez besoin pour une installation d'échafaudage sûre et efficace.

FAQ sur les échafaudages Ringlock

Quelle est la capacité de charge de l'échafaudage Ringlock ?

La capacité de charge varie selon la configuration et les composants utilisés, mais elle supporte généralement entre 500 et 750 kg par baie. Consultez toujours les tableaux de charge du fabricant pour obtenir des données précises.

L'échafaudage Ringlock peut-il être utilisé pour des formes complexes ?

Oui, l'échafaudage Ringlock est très polyvalent et peut être utilisé pour les échafaudages droits, circulaires et inclinés grâce à son système de connexion multidirectionnel.

En combien de temps peut-on monter un échafaudage Ringlock ?

La conception modulaire et l'assemblage sans outil permettent un montage plus rapide par rapport aux échafaudages traditionnels, réduisant ainsi les coûts de main-d'œuvre et les délais des projets.

L'échafaudage Ringlock est-il sûr ?

Oui, Ringlock est conforme aux normes OSHA et de sécurité internationales. Les connexions sécurisées et la structure modulaire du système offrent une stabilité et une résistance accrues aux travailleurs en hauteur.

Comment stocker les échafaudages Ringlock ?

Entreposez-les au sec, à l'abri du sol et évitez d'exposer les composants aux intempéries pendant de longues périodes. Vérifiez régulièrement l'absence de rouille ou de dommages et réparez les composants si nécessaire.