Introduzione

Le impalcature H Frame sono un componente essenziale nel settore edile, in quanto forniscono una piattaforma stabile e sicura per i lavoratori che svolgono attività ad altezze elevate. Noto per la sua facilità di montaggio, durevolezza e convenienza, questo sistema di impalcature è ampiamente utilizzato in vari settori, tra cui edilizia, progetti infrastrutturali e manutenzione industriale. Questa guida esplora la struttura, le caratteristiche, le applicazioni, i protocolli di sicurezza e l'utilizzo globale delle impalcature H Frame, offrendo preziose informazioni per professionisti e appaltatori.

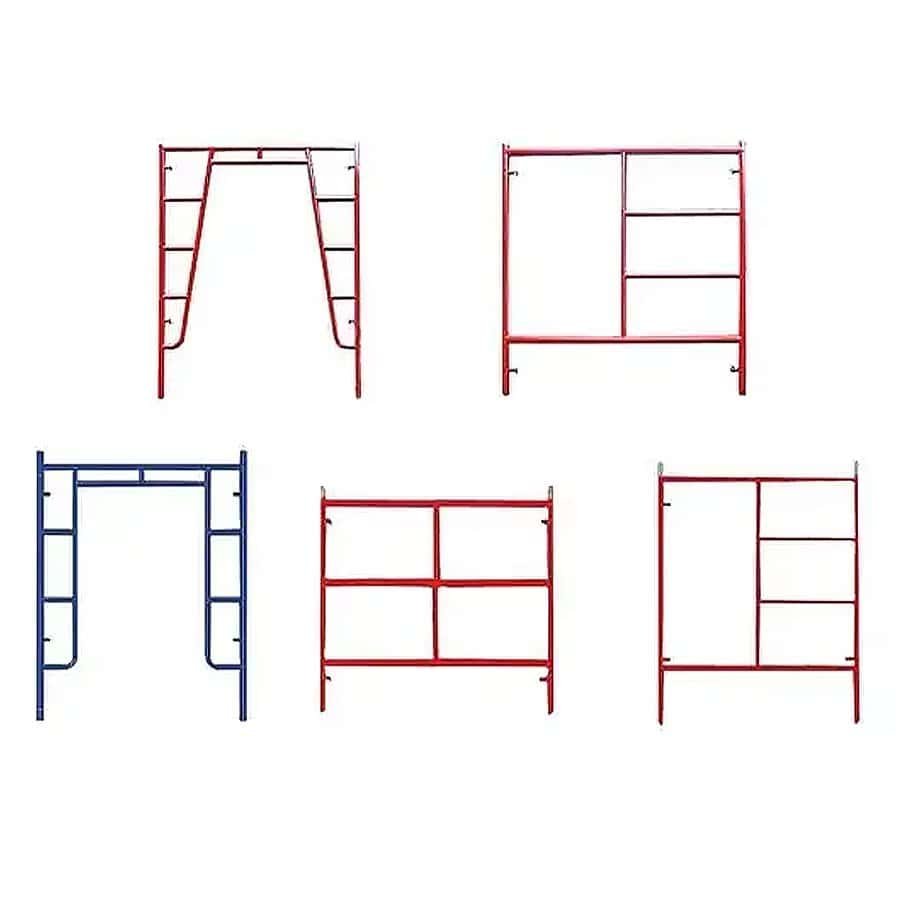

Che cosa sono le impalcature a telaio H?

I ponteggi con struttura ad H sono un sistema di supporto temporaneo ampiamente utilizzato e svolgono un ruolo fondamentale nei progetti di costruzione e manutenzione, grazie alla loro esclusiva progettazione strutturale e ai vantaggi multidimensionali.

Questa impalcatura è caratterizzata da un telaio verticale a forma di "H" come nucleo, collegato da controventi orizzontali per formare un sistema portante stabile. Il telaio è solitamente realizzato in acciaio ad alta resistenza o in lega di alluminio leggero, garantendo durevolezza e robustezza, mentre i componenti della piattaforma sono realizzati in tavola da ponteggio o compensato, bilanciando sicurezza e praticità.

Come sistema prefabbricato modulare, l'impalcatura a telaio H è rinomata per la sua facilità di assemblaggio, consentendo una rapida installazione in loco. Vanta un'eccellente capacità di carico e adattabilità spaziale, garantendo la sicurezza dei lavoratori in quota e adattandosi a diversi scenari di costruzione.

Con i suoi vantaggi combinati di stabilità, economicità e flessibilità, l'impalcatura a H è diventata la soluzione preferita per le piattaforme di lavoro elevate nell'edilizia moderna. Migliora significativamente l'efficienza del lavoro e riduce i costi del progetto, rendendola una risorsa inestimabile nel settore.

Componenti principali del ponteggio a telaio H

Le impalcature a telaio H comprendono telai verticali a forma di H, controventi e traverse orizzontali. Questi componenti si incastrano per formare una struttura rigida che supporta lavoratori e materiali a varie altezze.

Le impalcature a telaio H sono costituite da diversi componenti chiave che lavorano insieme per fornire una struttura stabile e sicura:

Telai H – Le strutture verticali primarie che forniscono supporto e stabilità.

Traverse trasversali – Connettori diagonali che aumentano la rigidità e impediscono il movimento.

- Registri orizzontali – Travi di supporto che aiutano a distribuire il peso in modo uniforme.

- Piastre di base – Posizionato nella parte inferiore per fornire una base stabile.

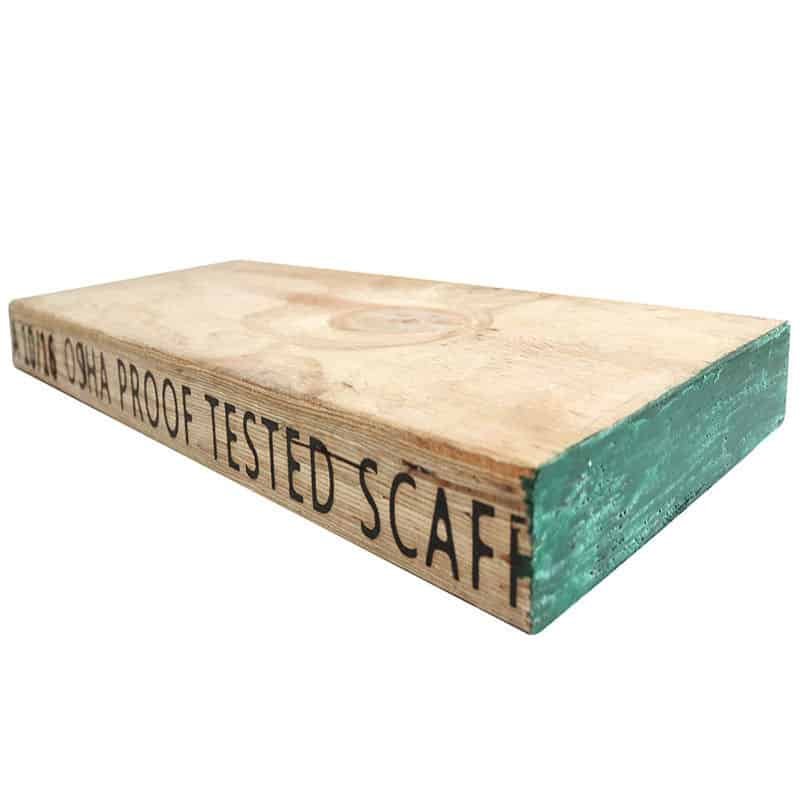

- Tavole di legno/piattaforme di compensato – Utilizzati come passerelle per consentire ai lavoratori di sostare e operare in sicurezza.

- Parapetti e Tavole di battiscopa – Aggiunto per la sicurezza dei lavoratori per prevenire cadute e lesioni.

- Perni di giunzione e giunti – Collegare in modo sicuro le diverse sezioni dell’impalcatura.

Caratteristiche principali delle impalcature a telaio H

1. Montaggio e smontaggio rapidi

Il ponteggio a telaio H è progettato come un plug-and-play sistema:

Telai, rinforzi e traversi prefabbricati si incastrano tra loro tramite perni e semplici meccanismi di bloccaggio

Per le baie di base non è richiesta alcuna complessa disposizione di tubi e giunti

Meno tempo speso nella misurazione e nell'allineamento dei singoli tubi

Questa semplicità riduce ore di lavoro, tempo di erezione, e il rischio di errori di assemblaggio, soprattutto sulle facciate degli edifici ripetitive.

2. Versatile per diversi progetti

I ponteggi con struttura a H possono essere adattati per:

Costruzione di edifici: muratura, rivestimento, intonacatura, verniciatura

Manutenzione di ponti e infrastrutture: accesso a moli, ponti e spalle

Impianti industriali: accesso a serbatoi, tubi e attrezzature

Organizzazione dell'evento: piattaforme e tribune temporanee dove sono consentite le impalcature a telaio

Variando:

Altezza e larghezza del telaio

Numero di ascensori

Posizioni della piattaforma

è possibile adattare l'impalcatura alle diverse forme degli edifici e ai requisiti del progetto.

3. Durata e capacità di carico

Le montature sono solitamente realizzate in:

Acciaio di alta qualità (spesso zincati a caldo per protezione dalla corrosione), o

lega di alluminio per sistemi più leggeri e facili da maneggiare

Se utilizzato secondo le tabelle di carico del produttore e i limiti di progettazione, il ponteggio con telaio a H offre:

Elevata capacità portante verticale

Buona resistenza alle forze laterali se adeguatamente rinforzato e legato

Lunga durata con una corretta manutenzione

4. Rapporto costo-efficacia

I componenti standardizzati e riutilizzabili riducono i costi delle apparecchiature a lungo termine

La geometria semplice riduce i tempi di progettazione e di montaggio

Ideale per appaltatori che gestiscono progetti edilizi residenziali o commerciali ripetitivi

Installazione di ponteggi a telaio

L'installazione di un ponteggio con struttura a H segue un processo semplice:

Le piastre di base sono posizionate in modo da garantire la stabilità.

I telai a H sono collegati tramite controventi e correnti trasversali.

Per garantire la sicurezza dei lavoratori vengono aggiunte piattaforme e ringhiere.

Per verificarne la stabilità vengono effettuati test di carico e ispezioni.

Le specifiche tecniche variano in base al produttore e ai requisiti del progetto, tra cui l'altezza del telaio, la larghezza e la composizione del materiale.

Applicazioni di ponteggi a telaio H

Le impalcature con struttura a H sono comunemente utilizzate in vari progetti edili e industriali.

- Nella costruzione di edifici alti, garantisce un accesso sicuro ai lavoratori a diverse altezze.

- È essenziale per la manutenzione dei ponti, poiché offre una piattaforma sicura per riparazioni e ispezioni.

- Nella verniciatura e nell'intonaco, garantisce stabilità agli addetti ai trattamenti superficiali.

- Inoltre, è ampiamente utilizzato nella cantieristica navale, negli impianti industriali e nell'allestimento di eventi, dove sono necessarie strutture di supporto temporanee ma resistenti.

L'adattabilità del sistema lo rende una soluzione indispensabile per le attività che richiedono un accesso elevato.

Altri suggerimenti per la sicurezza

Per garantire un utilizzo sicuro, le impalcature H Frame devono essere conformi alle normative di sicurezza del settore, come gli standard OSHA, ANSI ed EN. Tali normative definiscono aspetti critici, tra cui la capacità di carico, le specifiche dei materiali e i requisiti di protezione dei lavoratori.

Si dovrebbero effettuare ispezioni regolari per identificare potenziali pericoli come usura strutturale, connessioni allentate o danni ai componenti chiave. Il personale qualificato deve supervisionare il processo di installazione e manutenzione, assicurando che tutti i protocolli di sicurezza siano rigorosamente rispettati.

Una formazione adeguata dei lavoratori è essenziale per prevenire cadute e altri incidenti. I dipendenti devono avere familiarità con le procedure di assemblaggio sicure, i limiti di peso e i protocolli di emergenza. Inoltre, l'uso di dispositivi di protezione individuale (DPI), come imbracature, caschi e calzature antiscivolo, è fondamentale per ridurre al minimo i rischi.

Inoltre, le impalcature devono essere erette su una superficie stabile e piana, con piastre di base e stabilizzatori utilizzati per migliorare la stabilità. La distribuzione del carico deve essere attentamente monitorata per evitare sovraccarichi, che potrebbero compromettere l'integrità strutturale. Implementando queste misure di sicurezza, il rischio di incidenti può essere notevolmente ridotto, garantendo un ambiente di lavoro sicuro per il personale edile.

Conclusione

Le impalcature H Frame sono una risorsa fondamentale nell'edilizia, offrendo un equilibrio tra sicurezza, durata e facilità d'uso. Il loro design modulare, la convenienza e la conformità agli standard di sicurezza internazionali le rendono una scelta preferita in vari settori e regioni. Che si tratti di edifici alti, manutenzione delle infrastrutture o progetti industriali, le impalcature H Frame forniscono una soluzione affidabile e adattabile per lavorare in quota. Mentre le richieste di costruzione globali continuano ad aumentare, questo sistema di impalcature rimane uno strumento indispensabile per garantire efficienza e sicurezza dei lavoratori.

Se stai cercando un'impalcatura H Frame di alta qualità per il tuo prossimo progetto, prendi in considerazione la possibilità di consultare un fornitore o un esperto di costruzioni di fiducia. Rimani informato sulle ultime tecnologie di impalcature e sugli standard di sicurezza per massimizzare l'efficienza e la sicurezza in loco. Contattaci oggi stesso per saperne di più su come l'impalcatura H Frame può migliorare i tuoi progetti di costruzione!