Formwork solutions

- Easy assembly, reducing installation time and labor costs. With modular components, can be quickly adapted to meet the unique needs of any construction project.

- Personalized approach to every project, offering customized formwork solutions that meet your specific site and design requirements.

- Trusted supplier to top construction firms and contractors worldwide.

what is Formwork

Formwork is a temporary structure used in construction to hold and shape concrete while it sets and hardens. It acts as a mold or frame that supports wet concrete until it gains enough strength to support itself. Once the concrete has cured, the formwork is removed, and the final concrete structure, such as walls, beams, columns, or slabs, is left behind.

Formwork Solutions for Construction

APAC offers a comprehensive range of formwork solutions designed to provide efficiency, strength, and safety across a variety of construction projects. Our formwork systems are ideal for high-rise buildings, bridges, tunnels, and industrial projects, ensuring reliable and cost-effective solutions for all your formwork needs.

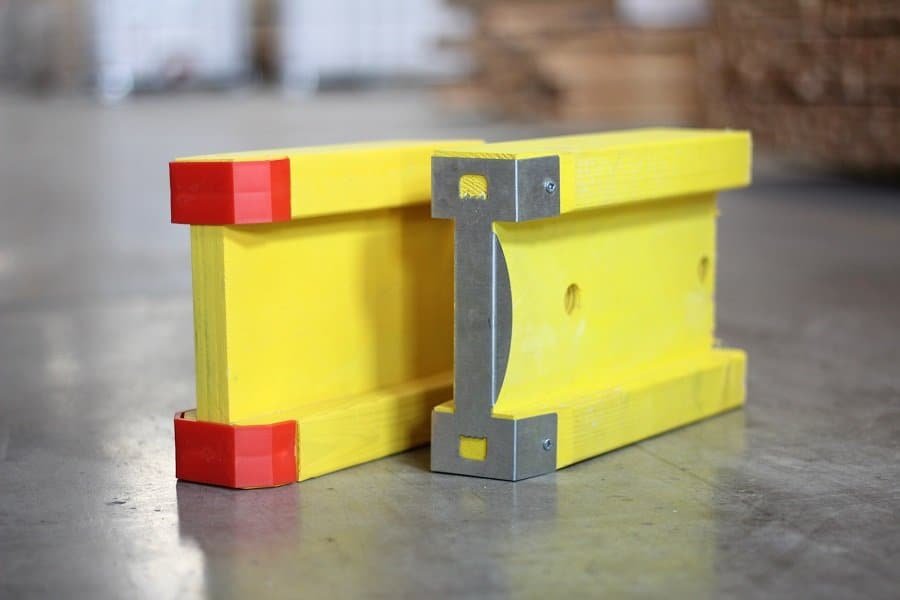

h20 Beam

Manufactured from high-quality materials, they provide strong support for large formwork panels, making them ideal for slabs, walls, and shoring systems.

قوالب الخشب الرقائقي

Plywood formwork is designed for quick and easy setup while providing a smooth, high-quality finish for concrete surfaces.

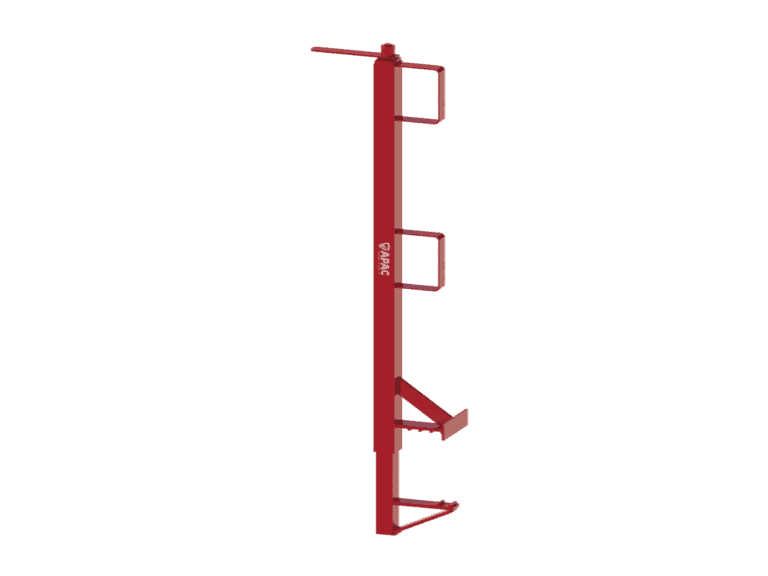

دعامة الدعم

APAC’s shoring props provide temporary support for formwork during the curing process of concrete. Our props are designed to withstand high loads and are fully adjustable, allowing for easy height adjustment to suit various formwork needs.

formwork accessories

APAC offers a wide range of formwork accessories to complement our formwork systems, ensuring seamless installation and operation. From clamps, pins, and connectors to wall ties and brackets, etc.

Contact APAC for More Formwork Solutions Details

Why Choose APAC Formwork Solutions

APAC’s formwork solutions provide the reliability and efficiency you need to complete projects on time and within budget. From H20 beams to formwork accessories, we have everything you need to create a solid foundation for your construction site.

High-Quality Materials for Durability and Performance

APAC formwork systems are constructed from high-strength materials like H20 beams and plywood formwork, designed to withstand heavy loads and provide long-lasting durability. Our systems are weather-resistant, corrosion-proof, and can be reused across multiple projects, delivering reliable performance at every stage of the construction process.

- Durable, reusable components

- Weatherproof and corrosion-resistant

- Long-lasting performance with minimal maintenance

Comprehensive Support from Start to Finish

At APAC, we provide more than just formwork products. We offer complete solutions, including project tracking, technical guidance, customized design, and installation support. Our team of experts ensures that your formwork system is tailored to your specific needs, providing end-to-end support for your project’s success.

- Customizable formwork solutions

- Complete project support, from design to installation

- Expert guidance for efficient setup and operation

Cost-Effective and Efficient

APAC’s formwork systems are designed to reduce labor costs and installation time, increasing overall project efficiency. Our solutions help you complete tasks faster, minimizing delays and ensuring that your project stays within budget. With modular components, our systems are adaptable and can be easily configured for various types of work, providing flexibility and cost savings for your projects.

- Fast, easy installation

- Modular systems for maximum flexibility

- Cost-effective solutions that help reduce labor and project costs

موثوق به من قبل المقاولين في جميع أنحاء العالم

تطبيقات القوالب

Formwork is an essential component in construction, used to create temporary molds or structures to support concrete until it hardens. APAC’s formwork solutions are ideal for a wide range of applications, providing reliable support and precise shaping of concrete structures.

- المباني الشاهقة

- الجسور والجسور العلوية

- Tunnels and Underground Structures

- Industrial Projects

- Residential and Commercial Buildings

- Infrastructure Projects

Formwork Solutions | The Ultimate FAQ Guide

1. Why is formwork used in construction?

Formwork is used to create the shape of concrete structures and provide support during the curing process. It ensures the proper alignment, dimensions, and strength of the concrete, contributing to the stability and integrity of the structure once hardened.

2. What materials are used in formwork?

Formwork is typically made from materials like timber, steel, aluminum, or plywood. Some systems use plastic or composite materials for specialized applications. The choice of material depends on factors like durability, strength, and the ease of assembly required for the project.

3. How long can formwork be reused?

Formwork systems can often be reused several times depending on the material and condition of the components. Steel and aluminum formwork systems are particularly durable, while timber formwork may have a shorter lifespan. Proper maintenance and quality inspection are essential to ensure that the formwork is safe for reuse.

4. What are the benefits of using modular formwork systems?

Modular formwork systems, such as H20 beams or Ringlock scaffolding, are highly flexible, allowing for easy assembly, disassembly, and adjustment on-site. They are ideal for projects that require customized shapes and sizes, reducing labor time and costs and improving overall efficiency.

5. Is formwork reusable?

Yes, most formwork systems, particularly those made from steel or aluminum, are designed for multiple uses across different projects. They are highly durable and cost-effective when reused, offering great value for large-scale and long-term construction projects.

6. How do you ensure the quality of formwork?

Quality control of formwork involves rigorous inspection during production, assembly, and after installation. It is essential to inspect for defects, ensure that components are correctly aligned, and check that the formwork is securely fastened to withstand the pressure of wet concrete.

7. What are the safety considerations when using formwork?

Safety is critical when using formwork, as improper installation can lead to collapses or injuries. Key safety measures include:

Ensuring the formwork is properly secured and braced

Ensuring correct alignment to avoid defects in the finished structure

Regular inspections to identify potential issues before they arise

8. How is formwork removed after the concrete hardens?

Formwork is typically removed once the concrete has cured and reached sufficient strength. The process involves carefully disassembling the formwork to avoid damaging the concrete. Timing for removal depends on environmental conditions, the type of concrete, and the specific project requirements.

APAC’s formwork solutions offer reliable, safe, and efficient methods for shaping concrete structures. With our high-quality materials and systems, you can ensure that your construction project meets both safety and performance standards.