LVL Scaffold Planks

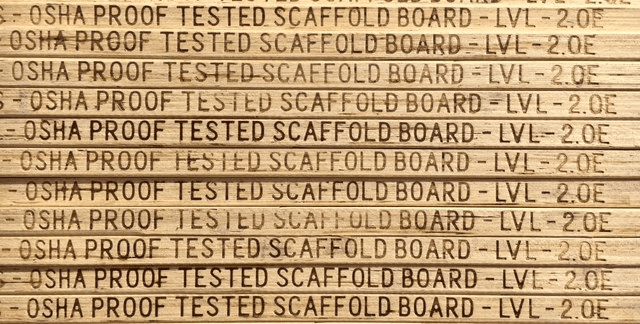

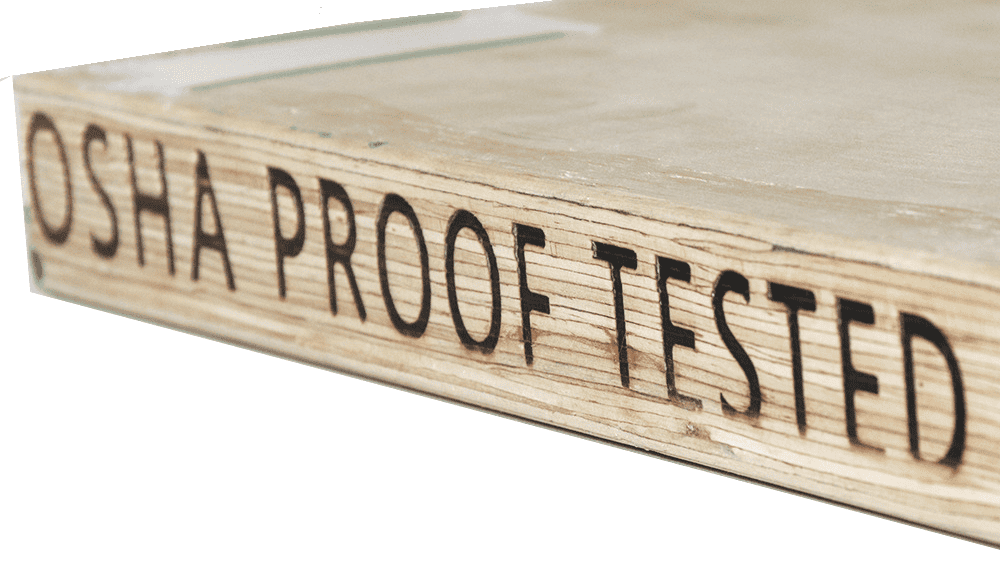

- Tested and certified to meet OSHA and ANSI safety requirements.

- Automated production + strict QC for repeatable batches—better for multi-project supply.

- Made with A-grade WBP phenolic glue, boiled at 100°C for 72 hours with no delamination—built for harsh site exposure.

- 10% lighter than solid wood, lower handling cost, faster install/dismantle, higher daily productivity for crews and rental turnarounds.

What is lvl scaffold planks

The LVL (laminated veneer lumber) scaffold plank is a high-strength and lightweight LVL scaffold plank used extensively throughout the construction industry.

The LVL Scaffold Plank is superior, lightweight, and reliable. Each plank undergoes stringent quality control and testing by AS/NZS standards, ensuring unmatched strength and safety.

Types of Scaffold Planks

We have a wide range of LVL scaffold plank products available, including various sizes and grades, to meet the diverse needs of our clients. Our dedication to quality and customer satisfaction has made us a trusted partner for businesses around the world.

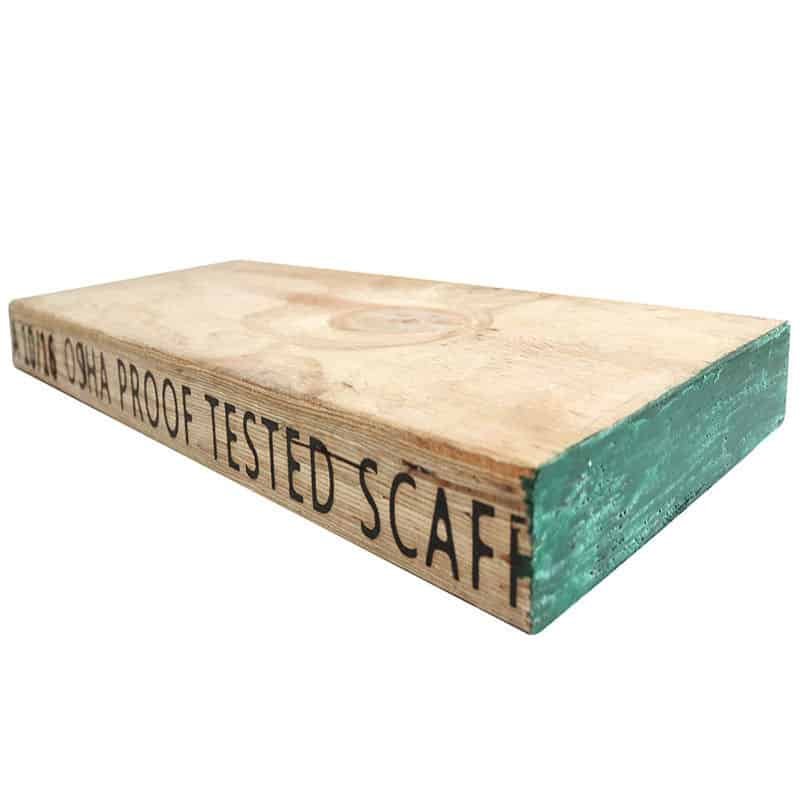

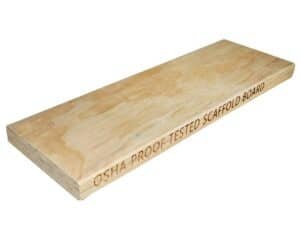

lvl scaffold plank without painting

The basic model of plank, which meets the standard requirements.

- MOQ: 17 Cubic Meter

lvl scaffold plank with painting

Customizable eye-catching colors, more suitable for worksite use.

- MOQ: 17 Cubic Meter

lvl scaffold plank with mental end

Fix the edge of LVL planks to prevent the board from splitting.

- MOQ: 17 Cubic Meter

LVL Scaffold Boards: Durable and Safe Solution for Construction

The wood scaffold boards are essential during construction, which provide a platform for workers to stand on while working at heights.

- 10% Lighter than Solid Wood.

- 100% Sustainable and Quality Spruce and Pine.

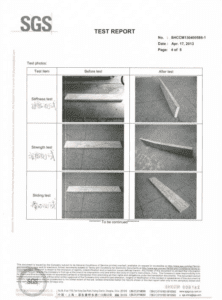

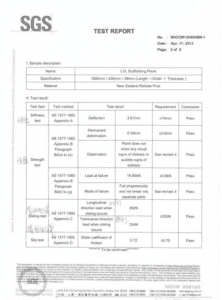

- Individually Proof Test Report by SGS.

- Strong, Lightweight, and Reliable Compared to Conventional Timber.

- Excellent Corrosion and Chemical Resistance.

- Customise Sizes to Perfectly with Your Scaffolding.

- Multiple Options for End Seal.

- Embossed Production Date and Company Logo.

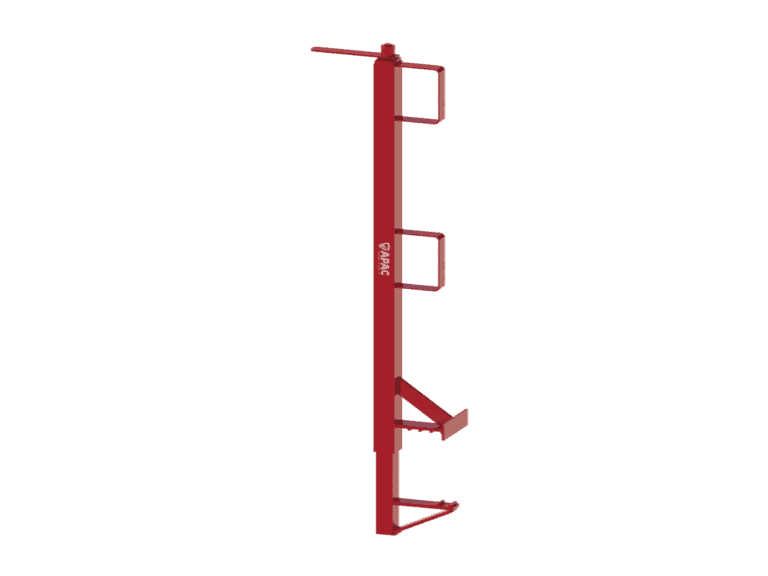

APAC is a manufacturer and supplier with many years of experience in exporting large quantities of LVL planks in China.

We have a strong reputation in the industry for producing high-quality scaffold planks that meet international OSHA Standards.

Our team is committed to delivering the best possible service to our customers and ensuring that each order is fulfilled to their satisfaction.

Why Choose APAC lvl plank

APAC LVL planks are built to give you repeatable platform performance, easier site control, and lower lifecycle cost across repeated jobs.

Factory Direct Scaffold Planks

We are a factory-direct manufacturer. So, we take pride in providing high-quality lvl planks at competitive prices.

Our production process includes the use of state-of-the-art, fully automated machinery. This allows us to produce products that meet and exceed industry standards with precision and consistency. We take pride in providing our customers with reliable and long-lasting planks.

Certified LVL Planks

LVL scaffold planks are tested and certified to meet strict safety standards, such as OSHA and ANSI, which ensure that they can withstand the rigors of construction work.

The planks are also treated with a non-slip surface to prevent workers from slipping and falling while working at heights.

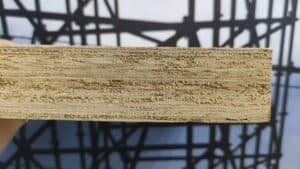

WBP Phenolic Glue / Waterproof

LVL scaffold planks are made from thin layers of wood veneers that are glued together with a strong adhesive. This process creates a strong and stable plank that is resistant to warping, twisting, and splitting.

Our LVL Scaffold Planks are manufactured using “A” grade WBP Phenolic Glue. The planks have been tested and boiled in hot water at 100 degrees for 72 hours without any delamination.

Strict Quality Control

To ensure quality, APAC LVL Scaffold Planks are produced under strict quality control and product certification. The wood we use is legally imported from New Zealand.

Our plank has been tested for bending strength, vertical load capacity, and moisture resistance to ensure it meets or exceeds industry standards. You can trust that our LVL plank will provide reliable and long-lasting support for your construction or renovation project.

Packing

When it comes to packaging, our transportation services are reliable and efficient, and we use only the best carriers to transport your products to their destination.

In addition, we offer customized packaging options to meet your specific needs and requirements.

- Packed on pallets. Wrapped with plastic, strengthen by iron belts.

- According to requirements.

Trusted by contractors worldwide

Applications of lvl scaffold plank

LVL scaffold planks are used as working platforms across a wide range of scaffolding setups worldwide, providing a stable deck for trades during façade work, masonry, painting, MEP installation, and general access.

In practice, an LVL scaffold plank is most often installed on ringlock, cuplock, frame scaffolds, or tube-and-clamp transoms to create walkways, loading/landing zones, and continuous platform runs along building elevations.

LVL Scaffold Plank | The Ultimate FAQ Guide

1. What are the OSHA requirements for scaffolding planking?

OSHA doesn’t mandate one specific “plank type,” but it does require the platform and its components (including planks) to be safe for the intended load and setup. Key planking-related requirements include:

Capacity (4:1 safety factor): scaffold components must support their own weight + at least 4× the maximum intended load.

Deflection limit: platforms must not deflect more than 1/60 of the span when loaded.

Selection/identification guidance: OSHA’s Appendix A (non-mandatory) provides span tables and notes solid-sawn planks should be selected per recognized lumber grading rules and identified by grade stamp.

2. What is the purpose of a scaffold plank?

A scaffold plank’s job is to create a safe, continuous working platform—supporting workers, tools, and materials at height—while maintaining required capacity and limiting deflection under load (so the deck stays stable).

3. What is the best wood for scaffold planks?

Globally, “best” is less about species and more about rated performance + grading/traceability. In the U.S., OSHA emphasizes selecting planks using recognized grading rules (Appendix A guidance).

Practically:

North America: scaffold planks are commonly graded softwoods (e.g., Southern Yellow Pine is widely used), but the key is the grade/rating and span table, not just the species.

EU/UK: timber scaffold boards are commonly to local standards (e.g., UK BS 2482 for timber boards), again emphasizing defined dimensions and grading.

4. How thick should a scaffold plank be?

It depends on the market/standard you’re working under:

UK BS 2482:2009 (timber scaffold boards): specifies 225 mm width and 38 mm or 63 mm thickness.

OSHA (U.S.): OSHA focuses on capacity/deflection and provides span guidance in Appendix A (e.g., tables for nominal 2×10 solid-sawn planks), rather than a single mandatory “thickness.”

5. When should scaffold planks not be used?

Do not use planks that are defective, damaged, or weakened such that they create a hazard. OSHA requires damaged/weakened scaffold components be repaired/replaced (with competent person oversight), and OSHA has clarified that a defect like a split isn’t automatically disqualifying if it does not create a hazard and the plank still meets the load requirements.

Practical “pull from service” triggers usually include: severe splits, rot/soft spots, delamination (engineered planks), crushed ends, deep gouges, or damage that affects bearing areas/support contact.

6. How to make scaffold boards waterproof?

You generally shouldn’t “DIY waterproof” a plank in a way that changes its rating or makes it slippery—follow the manufacturer and your local compliance practice. Practical, widely used measures are:

Storage & handling: keep boards off the ground, dry, and out of standing water; good storage is often the biggest factor in service life.

End sealing/protection: use end bands/caps and ensure ends are sealed (ends are where moisture damage often starts).

Factory coatings (preferred): if you need water resistance, specify boards/planks supplied with approved coating/edge sealing and documented performance—avoid site-applied coatings that reduce slip resistance.