What is Safety Net

A safety net is a critical protective measure used mainly in construction to prevent injuries or deaths caused by falls or falling objects. Safety nets are usually made from strong materials like nylon or polypropylene, designed to catch and safely stop a falling person or debris. This helps reduce the risk of serious injuries or fatalities.

In construction, safety nets are vital parts of fall protection systems. They provide passive safety, meaning that once installed, they work automatically without needing any action from workers. This is a big advantage over active safety measures, like harnesses, which depend on workers’ correct use and maintenance.

Types of Safety Net

There are several types of safety nets, each designed for specific uses and levels of protection. The main types are debris nets, fall protection safety nets, etc. Knowing the different types of safety nets helps in choosing the right one for a specific situation.

Debris Net

Debris nets are designed to catch and hold falling objects, preventing them from injuring workers or damaging property below. These nets are typically used on construction sites where materials, tools, or debris might fall from higher work areas. The main purpose of debris nets is to enhance site safety by creating a barrier that catches falling objects, reducing the risk of accidents.

Debris nets are usually made from high-density polyethylene (HDPE) or other tough materials that can handle the impact and weight of falling debris. Besides protecting workers, debris nets also help keep the worksite cleaner and more organized by containing debris in one place.

Fall Protection Safety Net

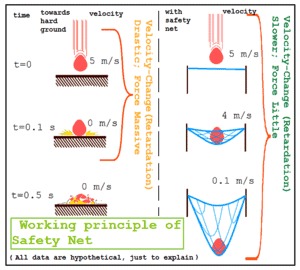

Fall protection safety nets are designed to catch workers who might fall from heights. They provide a critical layer of protection on construction sites, bridges, high-rise buildings, and other elevated work environments. These nets are made from strong materials like nylon or polypropylene, which are capable of absorbing the energy of a falling person and reducing the impact force.

The main function of fall protection safety nets is to stop a fall and minimize the potential for injury. They are usually installed below the work area and must be securely anchored to a stable structure. Fall protection safety nets are rigorously tested to ensure their effectiveness and reliability in real-world conditions.

Vertical Safety Nets (Façade Nets)

Definition: Large nets used as façade wraps or vertical barriers.

Function: Prevent debris from leaving the work zone and sometimes serve a visual barrier.

Applications:

High-rise façades under construction.

Façade scaffolding in city centers.

Bonus: Often combined with branding or advertising mesh, turning a safety measure into a marketing opportunity.

Specialized Safety Nets

Beyond standard categories, projects sometimes demand custom net solutions:

Helideck nets: Used offshore to prevent skids/slips on helicopter landing pads.

Tunnel nets: Installed in underground or mining projects to catch falling rock/debris.

Custom nets: With UV stabilizers, anti-static coatings, or flame-retardant treatments for extreme environments.

How to Install the Safety Net

Proper installation of safety nets is crucial for their effectiveness in protecting workers and preventing accidents. Here are the general steps for installing a safety net:

- Site Assessment and Planning: Conduct a thorough assessment of the site to determine where safety nets are needed. Consider the height, potential fall distance, and types of hazards present. Based on this assessment, create a detailed installation plan.

- Select Appropriate Safety Nets: Choose safety nets that meet the site’s specific needs and the type of work being done. Ensure that the nets comply with relevant safety standards and regulations.

- Anchor Points: Identify and establish strong anchor points for securing the safety nets. These anchor points must be capable of withstanding the forces generated by a fall or falling debris. Common anchor points include structural beams, columns, and other fixed elements of the building or structure.

- Net Placement: Position the safety nets below the work area or along the perimeter of the structure, ensuring they cover the necessary zones where falls or debris might occur. The nets should be installed with adequate overlap to prevent gaps.

- Secure the Nets: Use appropriate hardware, such as clamps, hooks, or ropes, to securely attach the safety nets to the anchor points. Ensure that the nets are taut and free from sagging, as loose nets may not effectively stop a fall or catch debris.

- Inspection and Testing: After installation, conduct a thorough inspection to verify that the nets are properly installed and free from defects. Perform load testing, if required, to ensure the nets can handle the expected forces.

- Maintenance and Monitoring: Regularly inspect and maintain the safety nets to ensure their continued effectiveness. Look for signs of wear, damage, or environmental degradation, and replace any compromised components promptly.

How to Choose the Safety Net

Proper installation of safety nets is crucial for their effectiveness in protecting workers and preventing accidents. Here are the general steps for installing a safety net:

- Site Assessment and Planning: Conduct a thorough assessment of the site to determine where safety nets are needed. Consider the height, potential fall distance, and types of hazards present. Based on this assessment, create a detailed installation plan.

- Select Appropriate Safety Nets: Choose safety nets that meet the site’s specific needs and the type of work being done. Ensure that the nets comply with relevant safety standards and regulations.

- Anchor Points: Identify and establish strong anchor points for securing the safety nets. These anchor points must be capable of withstanding the forces generated by a fall or falling debris. Common anchor points include structural beams, columns, and other fixed elements of the building or structure.

- Net Placement: Position the safety nets below the work area or along the perimeter of the structure, ensuring they cover the necessary zones where falls or debris might occur. The nets should be installed with adequate overlap to prevent gaps.

- Secure the Nets: Use appropriate hardware, such as clamps, hooks, or ropes, to securely attach the safety nets to the anchor points. Ensure that the nets are taut and free from sagging, as loose nets may not effectively stop a fall or catch debris.

- Inspection and Testing: After installation, conduct a thorough inspection to verify that the nets are properly installed and free from defects. Perform load testing, if required, to ensure the nets can handle the expected forces.

- Maintenance and Monitoring: Regularly inspect and maintain the safety nets to ensure their continued effectiveness. Look for signs of wear, damage, or environmental degradation, and replace any compromised components promptly.

FAQs on Safety Nets in Construction

Q1: What is the difference between a personnel safety net and a debris net?

A: The two serve different but complementary purposes.

Personnel safety nets are designed to catch and arrest a falling worker, absorbing the impact forces through the net’s elasticity. They must meet stringent standards like EN 1263-1 (Europe) or OSHA Subpart M (U.S.), ensuring they can handle the weight and dynamic force of a person falling from height. They are installed horizontally, close beneath the work surface, for maximum effectiveness.

Debris nets, on the other hand, are not designed to stop people. Their role is containment — catching falling materials, tools, or fragments from demolition, thereby preventing injuries to those below and avoiding property damage. These nets are lighter, with smaller mesh sizes (often 2–10 mm) made from polyethylene or flame-retardant fibers.

On many sites, you’ll see both types used together: a heavy-duty fall arrest net beneath a bridge deck, with debris netting layered over scaffolding to stop tools from striking pedestrians.

Q2: Are safety nets mandatory under OSHA or EN standards?

A: Yes, safety nets are legally required in specific scenarios where fall hazards exist and other fall protection systems (like guardrails or personal fall arrest harnesses) are impractical.

Under OSHA 1926.105 and related provisions, safety nets must be used whenever workplaces are more than 25 feet above the ground or water and guardrails are not feasible.

In the EU, EN 1263-1 and 1263-2 define requirements for fall arrest nets, and many local regulations (such as the UK Work at Height Regulations 2005) mandate collective protection measures like nets as a priority before relying solely on PPE.

- In Australia and New Zealand (AS/NZS 1891 & 4389), safety nets are considered part of the hierarchy of controls, often required in bridge works, roof jobs, and industrial maintenance.

The key message: regulators increasingly favor collective protection like nets, because they protect all workers in the zone instead of just those wearing harnesses.

Q3: How often should safety nets be inspected?

A: Inspections are not optional — they are a critical part of compliance and safety assurance.

Before every use: Nets must be visually checked for tears, cuts, abrasions, or loose knots.

After adverse weather: Storms, high winds, or exposure to chemicals can compromise fibers.

At regular intervals: Weekly checks are standard in most jurisdictions, with inspection logs kept for traceability.

After any fall or heavy impact: A net that has arrested a fall or caught a large object must be removed from service and either tested or replaced.

Q4: Can safety nets be reused after a fall?

A: Reuse depends on the extent of impact and the net’s condition after inspection.

If a worker or heavy object has fallen into the net, the fibers, knots, and edge ropes may be stretched beyond safe limits.

A competent person must carry out a detailed inspection — checking for elongation, broken mesh strands, and damaged border ropes.

In many cases, especially under EN 1263, nets that have arrested a fall must be taken out of service or sent for manufacturer testing.

My advice: treat nets like airbags in cars — once they’ve absorbed an impact, assume they are compromised unless proven otherwise.

Q5: What mesh size is standard for debris nets?

A: Mesh size is determined by what you need to contain.

- For general construction debris, 2–10 mm mesh is common.

- Smaller mesh (2–5 mm) prevents screws, nails, and fine fragments from escaping — ideal for urban façade scaffolding where public protection is critical.

- Larger mesh (up to 10 mm) may be used in demolition zones where heavy debris is already managed through controlled drop zones, but dust and smaller fragments are less of a concern.

Always balance weight, airflow, and containment: too small a mesh may act like a sail in high winds, stressing the scaffold. Too large, and objects slip through.

Conclusion

Safety nets in construction are vital for protecting workers and the public. There are different types of safety nets for different needs. Debris nets catch falling objects, keeping areas below safe. Fall protection safety nets catch workers who fall from heights. Specialized nets, like perimeter and scaffold nets, provide extra protection. Each type of net is made from strong materials and must meet safety standards.

Proper installation and maintenance are crucial. Choosing the right net involves considering the type of work, strength, compliance, size, installation, maintenance, and cost. Safety nets save lives and reduce injuries on construction sites.

They create a safer work environment and help ensure projects are successful. Understanding the types of safety nets and their uses is essential for improving safety in construction.