Shoring Props

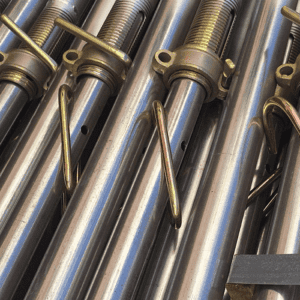

Shoring props are retractable tubular steel props consisting of an outer tube, an inner tube, and adjustable fittings. The inner and outer tubes are usually fitted with a flat metal plate at one end to provide additional support areas.

APAC’s adjustable shoring prop also called Acrow Prop, adjustable jack post, adjustable steel post, adjustable steel column, adjustable steel prop, adjustable steel shoring post, and even the lally column. They are designed to support a range of formwork and falsework applications, floors, ceilings, openings, and temporary beams.

Shoring Props : Made in China,Used Worldwide

APAC shoring prop strictly conforms to BS4360 and EN1065 standard, we also provide you simple and innovative design, and use high yield strength steel materials.

Our shoring props are available in five sizes covering a range from 1040mm to 4900mm with axial compression working load limits ranging from 7kN to 42.5kN. The outer tube diameter of the shoring prop is 60.3mm, the head and base plates normally are 150x150x6mm, on the center of the plate has a 38mm diameter hole.

APAC shoring prop is fast to erect in three simple steps, and are able to be handled by a single person, ensuring reliable and economical formwork and scaffolding applications.

Your Well-made Shoring Props

Shoring Props are used in the construction industry for temporary support of ceilings, walls and trenches (shoring). To install, first stand the shoring prop into the work area, adjust the height so that it almost fills the gap, and insert the pins to lock the inner and outer shoring prop tubes. Any remaining gap is then closed with screws until it is securely fastened to the support area.

Shoring props are mostly used for shoring: temporary support during building repair or alteration work, rather than scaffolding: an access platform for workers. Typical use is to support existing horizontal beams for table moldings.

You can have an inner tube in diameter of 40mm and 48mm for APAC’s shoring prop as well. When the inner tube diameter is 40mm/48mm, the outer tube will be 48mm/56mm.

APAC’s shoring prop jacks are widely used in scaffolding and concrete formwork support in Europe. The height of the props is adjustable, you can ask APAC to design and customize the height according to your slab /floor height.

The components of the shoring prop include prop outer tube, inner tube, G pins/ straight pins, top and bottom steel plates, prop nuts and handles etc.

APAC shoring prop can be used for multiple applications, such as the construction of slabs, pier caps, tunnel vaults, bridge decks, or any other concrete structure that requires the use of falsework.

Post Shore Prop Size to UK Concrete Construction

Item No. | Height | Weight (kgs) | Wall Thickness (mm) | Diameter of the tube(mm) | ||

Closed (mm) | Extended (mm) | kgs | Outside | Inside | ||

No.0 | 1040 | 1830 | 12.95 | 3.6/3.2 | 60 | 48 |

No.1 | 1750 | 3130 | 18.64 | 3.6/3.2 | 60 | 48 |

No.2 | 1980 | 3350 | 19.55 | 3.6/3.2 | 60 | 48 |

No.3 | 2590 | 3960 | 22.57 | 3.6/3.2 | 60 | 48 |

No.4 | 3200 | 4880 | 26.36 | 3.6/3.2 | 60 | 48 |

Steel Material S235 Or S355 Upon Option. Top and Base Plate : 150x150x6mm. Special size avaliable.

Middle Duty Post Shores to United States of America

Item No. | Height | Weight (kgs) | Wall Thickness (mm) | Diameter of the tube(mm) | ||

Closed (inches) | Extended (inches) | kgs | Outside | Inside | ||

PS-1F | 5’1″ | 9′ | 9.3 | 2.00 | 56 | 48 |

PS-2F | 6′ | 11′ | 9.7 | 2.00 | 56 | 48 |

PS-3F | 8′ | 13′ | 11 | 2.00 | 56 | 48 |

PS-4F | 10′ | 15′ | 15.9 | 2.00 | 56 | 48 |

Steel Material S235 Or S355 Upon Option. Top and Base Plate : 110x110x5mm. Special size avaliable.

Heavy Duty Post Shores to United States of America

Item No. | Height | Weight (kgs) | Wall Thickness (mm) | Diameter of the tube(mm) | ||

Closed (inches) | Extended (inches) | Outside | Inside | |||

PS-1B | 5’9″ | 10’3″ | 17.2 | 2.5/3.6 | 60 | 48 |

PS-2B | 6’6″ | 11′ | 18.8 | 2.5/3.6 | 60 | 48 |

PS-3B | 8’6″ | 13′ | 20.6 | 2.5/3.6 | 60 | 48 |

PS-4B | 10’6″ | 16′ | 25.4 | 2.5/3.6 | 60 | 48 |

Steel Material S235 Or S355 Upon Option. Top and Base Plate : 150x150x5mm Special size avaliable

Quality assurance

Choose your material and surface treatment

We usually use S235 steel or S355 steel, both of which are commonly used in the industry. S355 steel will make the shoring prop have a better loading rating, so we recommend you use S355 steel.

APAC provides OEM service for the shoring prop, the surface treatments you can find here are hot-dipped galvanized, galvanized steel, painting, and powder coated.

APAC is able to offer you shoring prop based on the weight load requirements. You can not only find the normal light-duty props. Other medium-duty and heavy-duty steel acrow props are available too.

What Can We Offer ?

Ringlock Scaffolding

APAC Ringlock scaffolding is used for all forms of access and support structures in the building, aviation, events, construction industries,ship building, industrial maintenance, ffshore construction.

Scaffold Towers

APAC scaffold towers also called 3T Industrial Scaffold Tower, is manufactured from Alloy 6061 T6 or Alloy 6063 T6 materials. They strictly conform to European standard EN 1004 and Australia/New Zealand Standard AS/NZS 1576.

H20 BEAM

APAC always believe that the values of the section modulus and the geometrical moment of inertia apply to new or used concrete formwork H20 beam. And you have to add analogously increased factor of safety needs for severely worm beams.

Brick Guards

APAC sales the only one-piece plastic brick guards, they are made in IS9001 certificated factory in China. We are a professional supplier with over 7 years experience, you can purchase directly from us.

Scaffold Tags

APAC Scaffold Tags are often designed to keep workers safe, but also to keep passersby safe. Construction Scaffold Tags prevent intruders and inform readers that entry may result in injury or death, ensuring that the site remains safe even without any workers present.

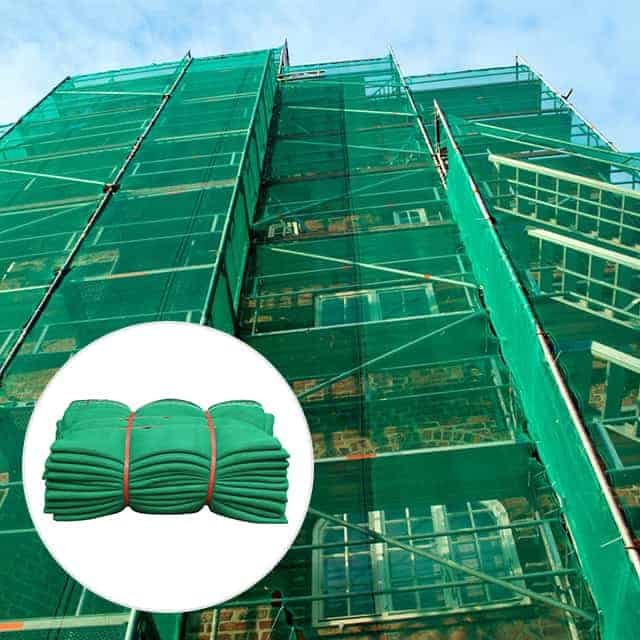

Scaffold Netting

APAC is one of the best construction site safety products supplier in China. We are committed to providing ranges of high-quality scaffold nets meet the safety standard.

More Question ?

When you are looking for shoring props for sale, APAC would be your best choice. We don’t only ensure you the quality by a strict quality control system, but also bring you more benefits in professional consulting. price, and service.

If you would like a door-to-door delivery service, simply tell us your address. APAC has a wide international forwarder and agents, we are able to send the shoring prop to your door.

Contact us now, let APAC help you get more shoring prop business, we believe it will be a win-win relationship for us.