aluminium scaffold tower

APAC aluminum scaffold towers, called 3T Industrial Scaffold Towers, are manufactured from Alloy 6061 T6 or Alloy 6063 T6 materials. They strictly conform to European standard EN 1004 and Australia/New Zealand Standard AS/NZS 1576.

Our alloy scaffold towers fully comply with the latest EN 1004 (Class 3) industrial standard and conform entirely to the requirements of the 3T erection and dismantling method as set out by HSE (Health & Safety Executive) and PASMA.

aluminium scaffold tower components

Aluminum scaffold tower Components include 150mm Locking Castors,2 Rung 1m Ladder Frame,2 Rung 1m Span Frame,3 Rung 1.5m Ladder Frame,3 Rung 1.5m Span Frame,4 Rung 2m Ladder Frame,4 Rung 2m Span Frame, Trap Door Platform, FixeD Platform, Horizontal Brace (red trigger), Diagonal Brace (blue trigger), Folding Toeboard, Small Outrigger, Medium Outrigger, and Large Outrigger.

Fixed Platform

Fixed Platforms have a non-slip finish for additional safety, with damage-resistant claws for maximum safety and reassurance whilst on the tower.

Horizontal Brace

The APAC Horizonal Brace offers customary security and structural rigidity within the APAC access scaffold tower builds.

Diagonal Braces

The APAC Diagonal Braces offer customary security and structural rigidity within the APAC access scaffold tower builds.

Folding Toe Board

Unique folding, single piece toeboard set made from plywood, making it much easier to transport and fit than heavier aluminium alternatives.

2 Rung Ladder Frame

2 Rung 1m Ladder Frames are used to increase the height of a mobile tower. The single width is 0.75m wide, and double-width is 1.35m.

3 Rung Ladder Frame

2 Rung 1.5m Ladder Frames are used to increase the height of a mobile tower. Single width is 0.75m wide, and double width is 1.35m.

4 Rung Ladder Frame

4 Rung 2m Ladder Frames are used to increase the height of a mobile tower. Single width is 0.75m wide, and double width is 1.35m.

Trap Door Platform

The trapdoor platforms provide access through the platform to move from one level to another, allowing the user to remain inside the scaffold.

150mm Castor w/Leg

The Castor is desingned to provide mobility to scaffolding tower, allowing the tower to roll across flat surfaces.

2 Rung Span Frame

2 rung 1m span frames are used to increase the height of a mobile tower. Single width is 0.75m wide, and double width is 1.35m.

3 Rung Span Frame

3 rung 1.5m span frames are used to increase the height of a mobile tower. Single width is 0.75m wide, and double width is 1.35m.

4 Rung Span Frame

4 rung 2m span frames are used to increase the height of a mobile tower. The single width is 0.75m wide, and double-width is 1.35m.

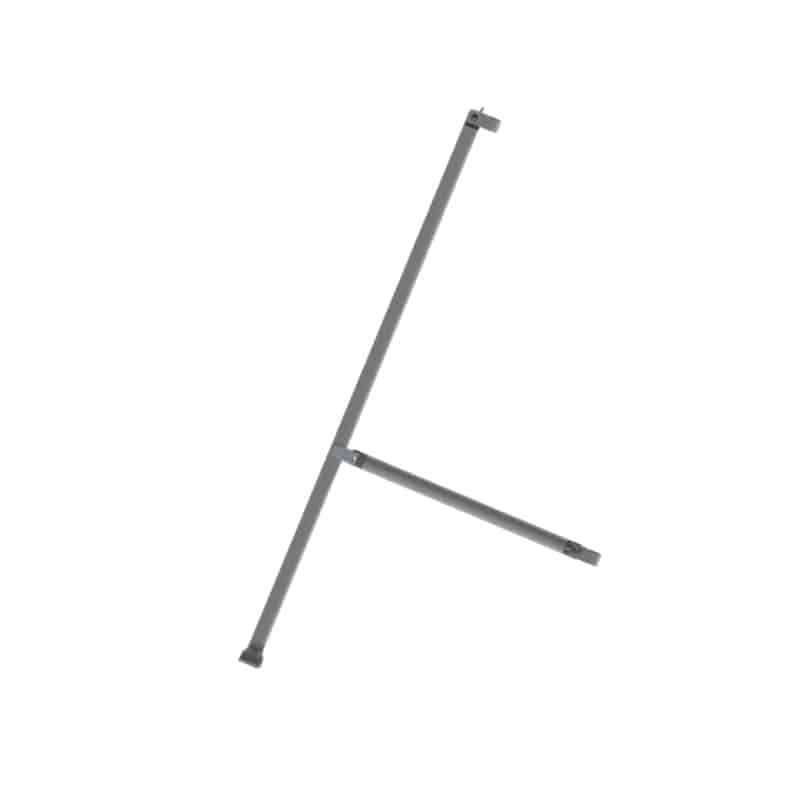

Small Outrigger

Static small outriggers/stabilisers and mobile outriggers provide increased stability for taller structures.

Medium Outrigger

Static medium outriggers/stabilisers and mobile outriggers provide increased stability for taller structures.

Large Outrigger

Static Large Outriggers/stabilisers and mobile outriggers provide increased stability for taller structures. Ideal for extremely high tower.

more details about aluminium scaffold towers

APAC design and manufacture the aluminium tower in China but not inferior products, we have very good quality products for you. The load of the alloy scaffold tower is extremely strong, 950kg weight rating. Height adjustable wheels from APAC enable you to use our scaffold towers on uneven surfaces, offering an adjustment of up to 300mm.

APAC unique piece, folding toeboard made from marine quality plywood – lighter than the aluminum equivalent and much easier to handle. We provide you with a color-coded bracing system for easy identification – simplifying assembly. APAC scaffold towers platform has a huge loading rating of 275kg.

APAC heavy-duty, dual locking casters are individually tested to 700kg, APAC unique frame locking pins for the scaffold towers are secured to the frame for safe holding. Non-slip, marine plywood platform provides you with great durability and grip in all weather conditions.

APAC Extra strong ladder section incorporated into the framework, to make climbing the scaffold towers effortless. Our frame tube diameter is 50.8mm – offering you superior strength and rigidity. Our articulated swivel rubber feet on outriggers have more contact with the ground–making the aluminium scaffold tower much safer.

Double Width Aluminium Scaffold Tower Specification

SPECIFICATION | CODE | HEIGHT | WIDTH & LENGTH | SLEF-WEIGHT(KG) | ||

| PLATFORM HEIGHT | TOWER HEIGHT | WORKING HEIGHT | ||||

| 2.0m Double Width Scaffold Tower | AST-DW-020 | 2000 | 3000 | 4000 | 1350*2000 | 100.59 |

| 3m Double Width Scaffold Tower | AST-DW-030 | 3000 | 4000 | 5000 | 1350*2000 | 121.72 |

| 3.5m Double Width Scaffold Tower | AST-DW-035 | 3500 | 4500 | 5500 | 1350*2000 | 160.3 |

| 4m Double Width Scaffold Tower | AST-DW-040 | 4000 | 5000 | 6000 | 1350*2000 | 162 |

| 4.5m Double Width Scaffold Tower | AST-DW-045 | 4500 | 5500 | 6500 | 1350*2000 | 185.47 |

| 5m Double Width Scaffold Tower | AST-DW-050 | 5000 | 6000 | 7000 | 1350*2000 | 202.05 |

| 5.5m Double Width Scaffold Tower | AST-DW-055 | 5500 | 6500 | 7500 | 1350*2000 | 203.75 |

| 6m Double Width Scaffold Tower | AST-DW-060 | 6000 | 7000 | 8000 | 1350*2000 | 213.45 |

| 6.5m Double Width Scaffold Tower | AST-DW-065 | 6500 | 7500 | 8500 | 1350*2000 | 232.88 |

| 7m Double Width Scaffold Tower | AST-DW-070 | 7000 | 8000 | 9000 | 1350*2000 | 234.58 |

| 7.5m Double Width Scaffold Tower | AST-DW-075 | 7500 | 8500 | 9500 | 1350*2000 | 251.16 |

| 8m Double Width Scaffold Tower | AST-DW-080 | 8000 | 9000 | 10000 | 1350*2000 | 252.86 |

| 8.5m Double Width Scaffold Tower | AST-DW-085 | 8500 | 9500 | 10500 | 1350*2000 | 309.17 |

| 9m Double Width Scaffold Tower | AST-DW-090 | 9000 | 10000 | 11000 | 1350*2000 | 310.87 |

| 9.5m Double Width Scaffold Tower | AST-DW-095 | 9500 | 10500 | 115000 | 1350*2000 | 316.61 |

| 10m Double Width Scaffold Tower | AST-DW-100 | 10000 | 11000 | 12000 | 1350*2000 | 318.31 |

APAC scaffold towers are suitable for indoor and outdoor use by professionals and DIY users. You can use our scaffold tower in a wide range of applications, such as when working on building walls, in a production plant, or in other facilities. Whether you are a scaffold towers distributor, reseller, wholesalers, or end-user like a contractor, APAC is always your best choice.

APAC has supplied aluminium tower since the year 2014, completely made in China factory. Based on the ISO9001 Quality Management System, APAC professional team strictly examines every procedure, from supplier verification to examination of raw materials, production, and finished products, to ensure the high quality of the scaffold tower products.

The value of APAC aluminum scaffold tower is clients’ interests first, quality. We always use the best quality components and add values where we can.

How to erect Aluminium Scaffold Towers

APAC aluminum tower can be set at 0.5m increments, ensuring supreme flexibility to work at a variety of heights.

As one of the best scaffold tower suppliers, APAC has a strict I9001 quality control system to guarantee you consistently top quality.

Our aluminum towers fully comply with the “3T” method of erecting and dismantling and comply with the policies of HSE (Health & Safety Executive).

APAC Builder Equipment is the vendor of some world’s top 50 construction companies and has been trading for many years of Scaffold Towers, so this peace of mind is worth having.

APAC offers you the manual in written form with the scaffold towers or you can download our PDF files directly, it is comprehensive and written in a way that is easy to understand.

Aluminium Scaffold Tower | The Ultimate FAQ Guide

Aluminum scaffold towers are highly demandable due to their lightweights. This gives them a high mobility advantage.

Moreover, aluminum scaffold towers’ high durability and heavy-duty support make them a popular choice in the scaffolding marketplace.

This FAQ content will guide you through some basic information and features about aluminum scaffold towers.

1. What Are Single-width And Double-width Aluminium Scaffold Towers?

The single-width aluminium scaffold towers are narrower compared to the double-width towers. Typically, they are 780 mm to 900 mm wide.

There are space limitations in different areas like corridors, balconies or staircases, etc. In these areas with space constraints, you can support your workers with the single-width working platform.

On the other hand, the double-width aluminium scaffold towers are wider. Generally, they are 1300 mm to 1500 mm wide. They have a larger base as well. This feature contributes higher stability to your scaffold tower.

So, your worker will get a more spacious and convenient working platform to work at an elevated height. You can use the extra space to store the materials while working temporarily.

The single-width and double-width aluminium scaffold towers are similar in terms of height. The typical aluminium scaffold towers have a height range of 9m to 14m with subsidiary variations.

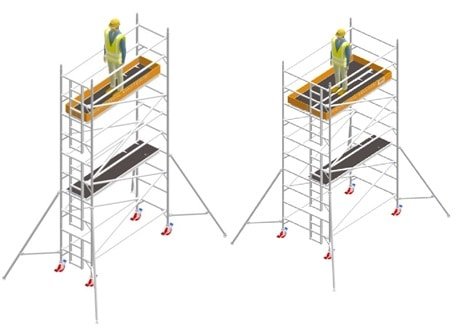

Figure 3 Single-width and Double-width Aluminium Scaffold Tower

Figure 3 Single-width and Double-width Aluminium Scaffold Tower

2. Can You Use Aluminium Scaffold Towers At High Wind Speeds?

It is strictly restricted to continue work on aluminium scaffolding towers at very high wind speeds. The restriction is applicable for all kinds of scaffold towers, regardless of size, material, or type.

If the wind speed exceeds designated levels, you must remove all the workers and any kinds of materials temporarily being stored from all working platforms. This is to conform to the safety precautions for your site.

You have to follow the different standard set of precautions for scaffolding towers at different wind speeds. This table is summarized for your easy considerations.

Wind speed (Km/hr) | Guidance |

29 | Cease all operations and using the aluminium scaffold tower. |

50 | Tie the aluminium scaffold tower to a rigid structure. |

74 | Dismantle the aluminium scaffold tower. |

3. What Are The Differences Between The Aluminium Scaffold Towers And The Traditional Scaffoldings?

The differences between the aluminum scaffold towers and traditional scaffoldings are:

Points of difference | Aluminum scaffold towers | Traditional scaffold towers |

Manufacturing material | Manufactured from aluminum or aluminum alloys | Manufactured from other types of metals |

Weight to body ratio | Lighter weight to body ratio | Heavier weight to body ratio |

Dead load consideration | Due to lightweights, you can avoid excess dead load for the total load calculation | Due to heavier material, you have to consider excess dead load for the total load calculation |

Maintenance | Requires less maintenance | Requires more maintenance |

Corrosion resistance | More resistant to corrosion | Less resistant to corrosion |

Erection efficiency | Requires less labor to erect | Requires more labor to erect |

Assembling and dismantling time | Can assemble and dismantle very quickly | Need more time to assemble and dismantle |

Interior usage | More efficient to set up at interior spaces | Less efficient for interior usage due to heavier weight |

Cost-effectiveness | Offers more cost-effectiveness in long-term considerations. | Less cost-effective over a long-term usage |

4. How Many Workers Can Simultaneously Work On An Aluminium Scaffold Tower?

The safe working load (SWL) determines how many workers can simultaneously work on an aluminium scaffolding tower. There are different sizes of aluminium scaffold towers with variable capabilities.

If you analyze the specifications provided by the manufacturer, you can find two SWLs mentioned. These are SWL per platform, and SWL per tower. The SWL or safe working load expresses the safe weight-bearing capacity.

It indicates the maximum weight each platform or tower can safely carry at a time. Divide this value with the average weight of a normal human being. The calculated value will let you determine how many workers can simultaneously work on each platform or tower.

5. Are The Aluminium Scaffold Towers Mobile?

Figure 4 – Lightweight Components Combined With Castor Wheels Provide Excellent Mobility Feature For Aluminium Scaffold Towers

Figure 4 – Lightweight Components Combined With Castor Wheels Provide Excellent Mobility Feature For Aluminium Scaffold Towers

You can make your aluminium scaffold towers portable by installing castor wheels at the lower base. Since the aluminium scaffold towers are very light, you can easily reposition them by rolling over a flat surface.

Before repositioning the tower, remove all kinds of weight from all the platforms. Dismantle the stabilizers and safety ties, followed by unlocking the safety lever in the castor wheel. Once you have repositioned the tower, lock the safety lever to cease the rolling scope.

More Question?

We are the scaffold towers experts having sold many thousands over the past 7 years.

APAC owns a knowledgeable sales team and sales service.

We offer 24/7 service to our clients, you can get in touch with us easily by phone call or email.