Shrink Wrap Roof

Shrink wrap roofs are used for temporary roofing projects. The shrink wrap is placed as the covering on the top scaffolding or some temporary frame. It acts as the main component of the roof’s weather coating layer.

The total shrink wrap roofing system will protect you against different weather agents like raindrops, wind, direct intense sunlight, heat, etc. So, your interiors will be safe from all the adverse damage.

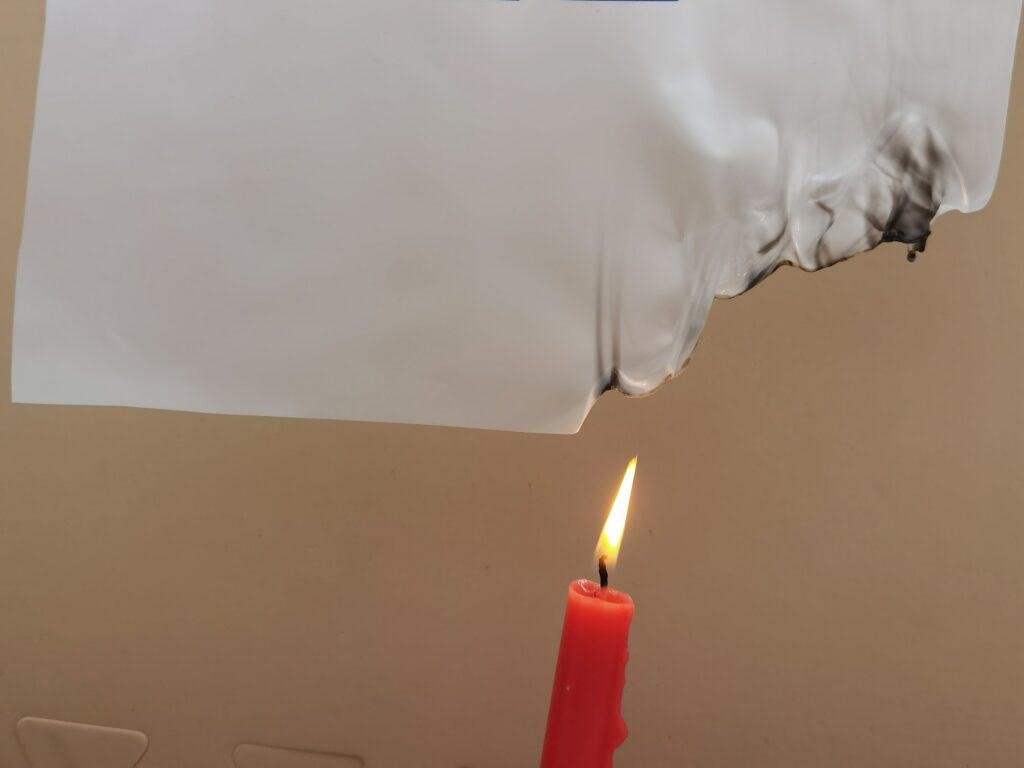

Fire Resistant

Conforms to fire protection standards DIN 4102 .

UV Protection

Effectively block ultraviolet rays and improve work efficiency.

High strength

Protect the workers from dust and scratch.

100% recyclable

Environmentally friendly, don't worry about causing pollution.

Why Our Shrink Wrap Roof is Your Best Choice?

APAC offers a complete line of shrink wrap roofing systems that can be used to wrap any size roof.This is a simple, easy-to-use temporary roof protection.

The shrink wrap film is wrapped around the roof, then the heat gun is used to melt the heat shrink wrap evenly, the film will shrink into the same shape as the roof, then you’ll get a waterproof, strong, and robust temporary roof.

The shrink wrap sheet is made of 100% PE and contains high-strength anti-ultraviolet (UV) components.

Its flexibility, elasticity, adhesion, abrasion resistance, and heat sealability are incomparable to ordinary roof sheets.

For most temporary roofing projects, a 300-micron thick white shrink film is used which has been tested for flame retardancy in accordance with European EN13501 standards.

Years of use in the temporary roofing industry have proven it to be effective in protecting roofs.

Your Leading Shrink Wrap Roof Supplier

The temporary roof industry has moved forward a tremendous amount in recent years with advances in safety and technology and standards. At APAC, we believe that roof sheeting should be moving forward also.

APAC gonna give you the most complete and honest guide to shrink wrap roofs, and how it’s different from every other product that’s on the market.

You can then decide for yourself if it’s going to be a good fit for you and your next project, and you’ll be able to advise your clients as well.

APAC’s production base has 5.4m and 7m wide multi-layer co-extruded shrink film blowing lines, as well as several imported German film blowing lines with a monthly output of 550 tons.

Fifteen years of production experience, QS certified production workshops, and ISO9001 quality management system provides reliable quality assurance for APAC’s shrink wrap sheet.

We usually packed rolls in pallets or carton or as customers requirements.

Quality Meets Excellence

We have a strict quality control management system to ensure that the best products are delivered to customers. We offer our clients a wide range of quality assurance services from product design and testing, material selection and sourcing, warehousing, distribution and delivery.

Our team of skilled professionals ensures that our products are manufactured under the highest standards of quality and safety. The entire manufacturing process is carried out in-house at our state-of-the-art facilities. Our in-house testing laboratories ensure that each and every product conforms to international standards.

Shrink Wrap Roof | The Ultimate FAQ Guide

1.What Material Is Used For Shrink Wrap Roofs?

A shrink wrap roof is a layer of plastic membrane. Manufacturers generally use low-density polyethylene (LDPE) in the manufacturing of shrink wrap roofs. Since the roofs are designed to experience harsh climatic conditions, they ensure that the material can withstand such abuse for a temporary period.

The shrink wrap roofs may vary in thickness from one manufacturer to another. But in general, you can find shrink wrap roofs with a 300-micron thickness that is sufficient to cover the purpose efficiently. The membrane is a lightweight and flexible plastic that you can easily install on the roof frame.

Another important feature why LDPE is used is due to its weather-resistant capabilities. The shrink wrap roofs have a good impact resistance. So, they can offer significantly high strength. Moreover, the UV ray cannot damage the shrink wrap roofs due to the anti-ultraviolet components.

2.What Are The Benefits Of Shrink Wrap Roofs?

The common benefits of shrink wrap roofs are:

- With shrink wrap roofs, you can ensure a tightly sealed containment system. It will help you to seal any gaps to avoid dust, moisture, pests, etc.

- The shrink wrap roofs are made from high-strength material. So, you can get robust protection for your structure.

The consideration of weight is a big issue for any temporary roofing project. With very lightweight shrink wrap roofing, you can totally keep the thoughts off the weight.

Figure 2 – A Shrink Wrap Roof Adds A Pleasing View To Your Temporary Roofing System

- Shrink roofs are made from materials with anti-UV components.

- Shrink wrap roofs are super cheap to install. So, this should be your perfect choice for the temporary roofing solution.

- Installing shrink wrap roofs requires very little effort and labor.

- You can install shrink wrap roofs for awkwardly shaped roofs.

- From small to large size of roofs, you can use shrink wrap for all sizes of roofs.

3.How To Set Up A Shrink Wrap Roof?

Follow these steps to set up a typical shrink wrap roof on a scaffolding.

- Make sure that the roof frame or scaffolding is complete where you want to install the shrink wrap roof.

- Install a handrail at the border perimeter of the roof to ensure the safety of the workers.

- If you are installing from a shrink wrap roll, then you need to cut them.

- Start by cutting a single piece first. Measure the length that is of greater length on your roof. You should keep an extra of 30 cm to 40 cm extra at each side to overlap the edge and fold. So, add 60 cm to 80 cm with the measured length. Use this measurement to cut from the shrink wrap roll through the length.

- Cut several similar-length pieces until you get enough to cover the width of the roof by placing them side by side. Place them to cover the whole roof maintaining a minimum overlapping sheeting length.

Figure 3 – Temporary Roof Scaffolding Using Shrink Wraps

- Keeping the extension overlap, fold the shrink wrap over the horizontal scaffold rail at one side. Cut the shrink wrap at positions with the vertical rail posts and place the two ends at two sides of the rail post. Tape the ends that you have placed at two sides. Use a rail clamp to secure the connection between the shrink wrap sheet and the horizontal scaffolding rail.

- Pull the shrink wrap gently at the other end to flatten its surface. Then fasten the other side following the same techniques. Then batten the shrink wrap sheet on the roof at regular intervals.

- Heat weld the extended portion you left at each side of the interior wall where you made the fold. Tape the edge of the welded extension.

- Again, tape the base of the vertical rail posts and the sheets. You must ensure that you are not leaving any gap to avoid water penetration.

- Finally, heat shrink the roof sheets using a heat blowing machine to complete the setup of the shrink wrap roofing.

The installation procedure may vary depending on the type of roof you are installing. For example, if you install on a double-pitched roof, you need to follow some additional steps. But for any type of roof structure, you can follow these general steps with small modifications.

4.How Long Can You Use A Shrink Wrap Roof?

Shrink wrap roofs are made for temporary usage. So, you cannot expect very long durability from this material. How long your shrink wrap roof will last depends on the weather conditions, especially the wind. In general, the manufacturers offer a warranty for six months, with some conditioning on wind speeds.

But you can use the shrink wrap roofs for about a year or more if the weather conditions are favorable. One of the great advantages of a shrink roof is that it does not get fragile, wrinkled, or weakened under the sun, which is a common concern with many materials.

Moreover, the sheet will remain as tight as you installed it at first. It will not be sagging with the passage of time. So, if you do not face too harsh weather conditions, you may use it for a very long time.

5.How do you set up a scaffold structure for a shrink wrap roof?

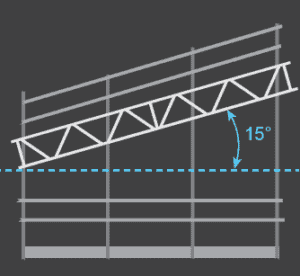

basic outline of a scaffold structure. On any structure we need a minimum of 10% pitch to avoid water puddling. So on a graph You’ll be looking at 10% minimum and also no more than a 30% maximum to allow safe working.

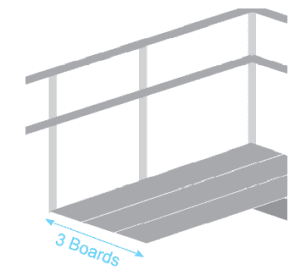

Now we have a basic outline of a structure, the first thing we would require as a triple boarded run around the perimeter of the roof.

You will need to be aware that any board installed on the roof. We need to be well clipped. So we were devised that board clipped in every corner, which will reduce the chance of the board coming loose in any movement as the sheeting will be fixed to these boards in places

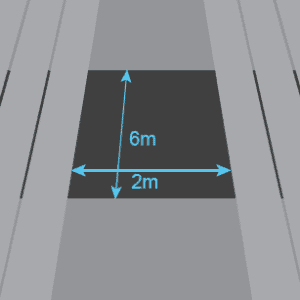

Next you will need to install triple boarded runs through the centre running parallel with the pitch of the roof. These boards would need to be spaced at a maximum of two m apart. Yeah. So that’s it for your boards on the roof.

Next you will need to install triple boarded runs through the centre running parallel with the pitch of the roof. These boards would need to be spaced at a maximum of two m apart. Yeah. So that’s it for your boards on the roof. The next thing you would require is a perimeter handrail. This will are safe working around the perimeter. Plus it would also act as anchor points for horizontal lanyard, horizontal lines,so you can install your lanyard so to allow safe working.

The next thing you would require is a perimeter handrail. This will are safe working around the perimeter. Plus it would also act as anchor points for horizontal lanyard, horizontal lines,so you can install your lanyard so to allow safe working.

6.How is the cost of shrink wrap roof VS blue tarp roof?

After a storm, shrink wrap roof is the most effective temporary roofing solution available.

let’s compare the cost to a blue tarp roof.

FEMA gov. states that the operation blue tarp roof material is designated to last 30 days.

Let’s take a 2000 square-foot roof for example.

A completed blue tarp on a roof this size including battens and sandbags is approximately two dollars and ten cents per foot.

In this example, it took six months for the insurance to approve the claim, and a new roof to be installed.

let’s assume you’re able to get double the lifespan that FEMA gov. suggests.

Then puts the blue tarps in our example being replaced three times before the new roof was installed.

Total cost for blue tarps in this example, $12600.

Some survey data shows that bule tarps fail an average more than five times, within six months of a major weather event during the life of an insurance claim.

Failed blue tarps cause additional internal damage, which can make you even more distracted.

Our complete shrink wrap roof system with one year warranty in this example is $8000.

If the roof took a year to be replaced instead of six months, the cost of bule tarps could be more than three times the cost of the shrink wrap roof system.

we know that insurance companies have 90 days to approve your claim.

why use a product that will often fail within that time frame, and cause more damage to your clients home?

The answer is simple.

Choose APAC shrink wrap roof, we give your client peace of mind, and give you the time you need to settle your quotes.

7.On What Types Of Roofing Systems Can You Install Shrink Wrap Roofs?

You can use shrink wrap roofs on different kinds of residential and commercial roofs like:

- Single-pitch roof

- Double-pitch roof

- Tiled roof

- Terrace roof

- Glass roof

- Mansard roof

- Gambrel roof

- Combined roof

- Butterfly roof, etc.

Figure 4 – Shrink Wrap Roofing Example

More Question?

If you’ve got an immediate question or you’ve got a project in mind that you’d like us to give you some help or advice.

Please give us a call or send us an inquiry, our super-specific and friendly team will be happy to help you.