Debris Net

Debris netting is made of HDPE, with the advantages of high strength, light weight, heat insulation,fireproofing and dust prevention.

It is mainly used in construction sites, shipbuilding & repairing, large equipment installation and other high-altitude workplaces, preventing people and objects from falling or to avoid injury from falling objects.

The debris netting can also be used as protective nets, fences, bird protection nets, etc. for a variety of purposes.

As A Debris Netting Supplier, APAC Is Your #1 Choice

Debris Netting is mainly used on scaffolding to keep any rubbish or debris contained on a building site. It improves site safety by reducing the risk of objects falling outside the working area. The containment of debris creates a safer working environment for workers and the general public.

The fine mesh design allows a good around of air circulation, but reduces the amount of wind and rain that can get through which makes for an improved and safer working environment.

APAC Debris Netting Series

Debris Netting is your important source of protection from debris that falls from the working deck. APAC debris netting series will help you improve the safety of on-the-street pedestrians, construction workers and adjacent properties.

Our heavy-duty, fire retardant, OSHA-compliant debris netting is made to wrap a building or job site in a cocoon of safety. It is the most economical and cost-effective solution for ultimate safety on your job site.

scaffold debris netting

Provide containment for scaffolding projects around your job site as a control debris mesh tarps and safety barriers, keeping continuous air movement

horizontal debris netting

Durable netting installed horizontally to provide worker safety, protecting workers from penitential falls and falling debris and objects on the ground

vertical debris netting

Designed for scaffolding enclosure and vertical debris protection, increasing the safety of workers and debris falling during construction.

heavy duty debris netting

Made from high tenacity knotless polypropylene and go through rigorous testing to ensure they meet construction industry standards

fire retardant debris netting

Made from knitted polyethylene with a reinforced edge boarder. It is typically used at construction jobsites and is UV treated.

printed debris netting

Adequate advertising on your construction project, it can be custom debris netting banners or temporary fence panel covers

DEBRIS NET by color

As a debris netting supplier, APAC has exported for over 5 years. Our debris netting is heavy-duty and durable.

We have many types of debris netting:

- white debris netting

- green debris netting

- grey debris netting

- blue debris netting

- black debris netting

- red debris netting

- orange debris netting

- pink debris netting

- Other colors on request

Premier debris netting Supplier in China

For top-quality debris netting, discover us – APAC Builders Equipment Co.,Ltd.

From small construction jobs to large industrial or commercial projects, we’ll meet and exceed your expectations with a reliable cost-effective service, giving you the benefit of more than 10 years in construction site safety business.

• Made from 100% high quality virgin material

• UV protection for sunlight exposure

• Tear resistant and remains flexible even in cold weather

• Provie an enclosure which allows air to pass through

• Contain tools and debris from falling, protecting worker and pedestrian safety

• FR (Flame Retardant NFPA 701) or NFR (Non-Flame Retardant) optional

• Application in both construction and agriculture industry

1) By Rolls +Poly bags

2) By packages + PE bag or wire wraped

For securing the debris netting, we advise using cable ties for a long term fitting or our elasticated Bungee Ties for use where the netting will be erected and taken down on a regular basis.

High Quality Debris Net

The debris netting design provides containment of small and chunk debris and is highly tear resistant. Debris Netting rolls include finished hemmed edges with reinforced eyelet button holes for fastening allowing for an easy, safe, and secure installation. All netting rolls are tightly packaged into clear poly bags with branded labels for easy shipping and handling.

All APAC Debris Netting is tested and approved to meet the standards in the industrial and construction industry.

Debris net for Wide Applications

● Contains Jobsite debris, tools & other materials

● Protects workers & pedestrians from falling objects

● Provides visual safety barrier

● Guardrail debris protection

● Scaffold & construction building enclosure

● Industrial plant & refinery maintenance

● Temporary jobsite barrier netting

● Safety fence, snow fence, barrier net

Debris Netting | The Helpful Guide for Importers

Q1 What Is Debris Netting?

Debris nettings are used in construction sites to protect construction workers and pedestrians from the risk of falling debris. The debris nettings are featured with small mesh sizes so that the construction wastes cannot escape through the small holes.

They are also helpful to contain other construction materials, worker’s tools, or any falling object. The debris nettings are frequently used in renovation and rehabilitation works on buildings at elevated heights. Common application scope for debris netting can be utilized in demolition projects with high frequency and risk of falling debris.

Figure 1 – Debris Nets In Construction Sites

Figure 1 – Debris Nets In Construction Sites

Q2 What materials are used in manufacturing debris netting?

The common material used in manufacturing debris netting is HDPE or high-density polyethylene due to its unique and beneficial properties. The material is suitable to withstand heavy abuse against tear. This feature is very useful prominently because of how the shape of debris is shaped.

The debris has sharp edges that might damage the net after frequent use. Moreover, the net’s high-strength property helps prevent small to large-sized debris or other falling objects.

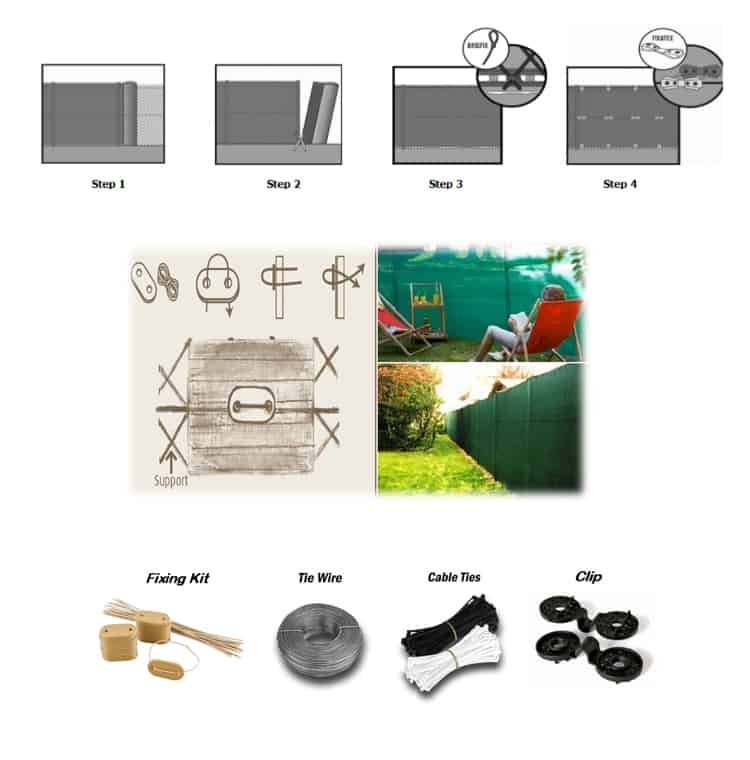

Q3 How to install debris netting for structures with open sides?

There are two methods of debris netting installation. You can either install them horizontally below a certain height to catch any falling scrap. Or you can install them vertically at the outer perimeter to stop any kinds of waste material from falling over.

You can use both these methods, but the vertical installation method at each edge perimeter is more suitable for buildings with open sides. Follow these steps for installation:

- The debris nets are required to be attached with vertical members like columns or scaffolding pipes, etc. So, before installation, you have to make sure these vertical components are ready.

- Mark the height at which you need to install the net. Common heights used in the construction sectors are at 5’, 3’6” heights. You can use other height options as long as it conforms to legal standards.

- The debris net should have an additional height that you need to fold inwards for toeboard overlap. According to legal standards, this toeboard overlap should be a minimum of 6 inches.

Figure 2 – Installation Procedure Of Nets In Open-sided Buildings

Figure 2 – Installation Procedure Of Nets In Open-sided Buildings

- Take the net and cut according to the perimeter length of the edge where you want to install it. You can also proceed with installation without cutting and finally trim once the installation is complete.

- You need to use wire ropes horizontally from one vertical member to the next to support the net. For the rope selection strictly follow the guidelines of the legal standards to choose strong rope to support the debris net at moderate wind speeds.

- Install the ropes from one end of the perimeter to the other end and rigidly attach at all the intermediate vertical posts. Make sure to attach them at the marked height.

- Install another piece of rope below the previous rope following the same method. The height should be in the middle between the previous height and the ground.

- Attach the top portion with the topmost wire rope using cable ties. You can also different kinds of plastic attachment clips for the attachment. But use them at close intervals to avoid any kind of sagging.

- Now, attach the net with the middle rope using the same techniques. In this case, you may use fewer attachment clips since this will help to hold against lateral force.

- Finally, fold the bottom part of the net with the toeboard overlap and use steel plates to attach them with the ground.

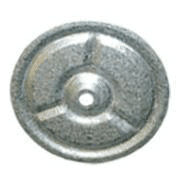

Figure 3 – Steel Plates For Toeboard Installation

Figure 3 – Steel Plates For Toeboard Installation

Q4 How Can The Debris Netting Benefit You?

The benefits of debris nets are as follows:

- Safety nets are critical elements of a fall protection system in any construction site. The risk of falling debris poses a huge threat as it may seriously injure any person passing by or working below. They will safeguard your workers from these risks.

- With a safe working environment, you can increase the efficiency of work in your job site by avoiding unnecessary disruptions and smooth workflow.

- With the usage of construction debris safety nets, you can conform to the mandatory legal standards in your construction site.

- Debris nets are very easy to install at the exterior border of the construction sites. So, this enables you with a cost-effective approach for safety elements.

- At elevated heights, material transportation is done by a crane system through the perimeter edge. The debris nets can benefit you for loading and unloading purposes since you can simply open up a space by removing the cable ties during material transportation. Once completed, you can again reinstall them very quickly.

- The debris nets are lightweight materials. So, with the high portability feature, you can easily transport and install them. You can also reuse them for different areas.

Q5 What are the legal requirements for debris netting in a construction site?

According to the occupational health and safety standards, the vertical debris nets should maintain a minim height of 42”±3” with sufficient toeboard safety facility. For horizontal safety nets, you should install them with an extension of 8’ from the working perimeter.

Q6 What mesh sizes are used in debris netting?

There are no fixed requirements on the mesh size, but you need to use a smaller mesh size to catch be able to trap all kinds of debris. In general, you can find debris nets with mesh sizes of 1/16”, 5/32”, or 1/4″.

Q7 Do debris bounce off from debris netting?

More Question ?

If you need debris netting or safety nets, you’re looking for scaffolding solutions for a large new build project, whatever your requirements, here is our three-point promise.

we’ll provide a free quote

We’ll comply with all the latest safety requirements

and we’ll make sure you’re totally satisfied before we consider our services done

Send the inquiry now, and contact APAC you can trust.

LET'S DISCOVER OUR OTHER WORKSITE SAFETY RANGES WHICH MIGHT INTEREST YOU!

why choose APAC

● 10+year OEM & ODM experience & one-stop solution

● Expert guide through the process to keep your project on time and on budget

● Regards quality as a basic factor for enterprise development

● Strict quality control system, guarantee TOTALLY customer satisfaction

● Fully worksite safety solutions with interchangeable components

● Capability to supply both bulk orders and smaller volumes

● Fast and efficient delivery to the whole world