Edge Protection for Steel Structure

Steel structures require specific edge protection systems that are designed to ensure the safety of workers during construction and maintenance activities. Steel structure edge protection is an essential component in providing a secure working environment for operators.

Steel structure edge protection systems are designed to be compatible with the construction methods used in steel structures. They are often adjustable, allowing for easy adaptation to various heights, angles, and configurations of the steel framework. This flexibility ensures that workers can safely access different areas of the structure during the construction process.

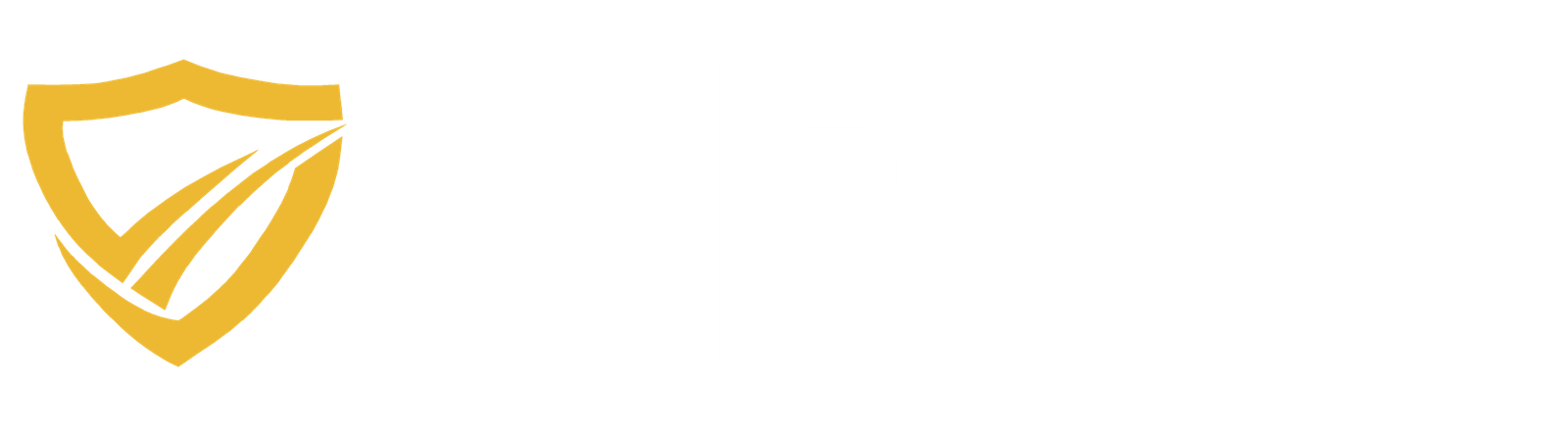

steel structure edge protection solutions

We mainly provide several ways to operate the system for steel structure edge protection solutions, such as top bolted, clamped, and welded to horizontal steelwork.

These systems above for the steel structure edge protection are classified by the fixing operation.

Why Choose Our Steel Structure Edge Protection

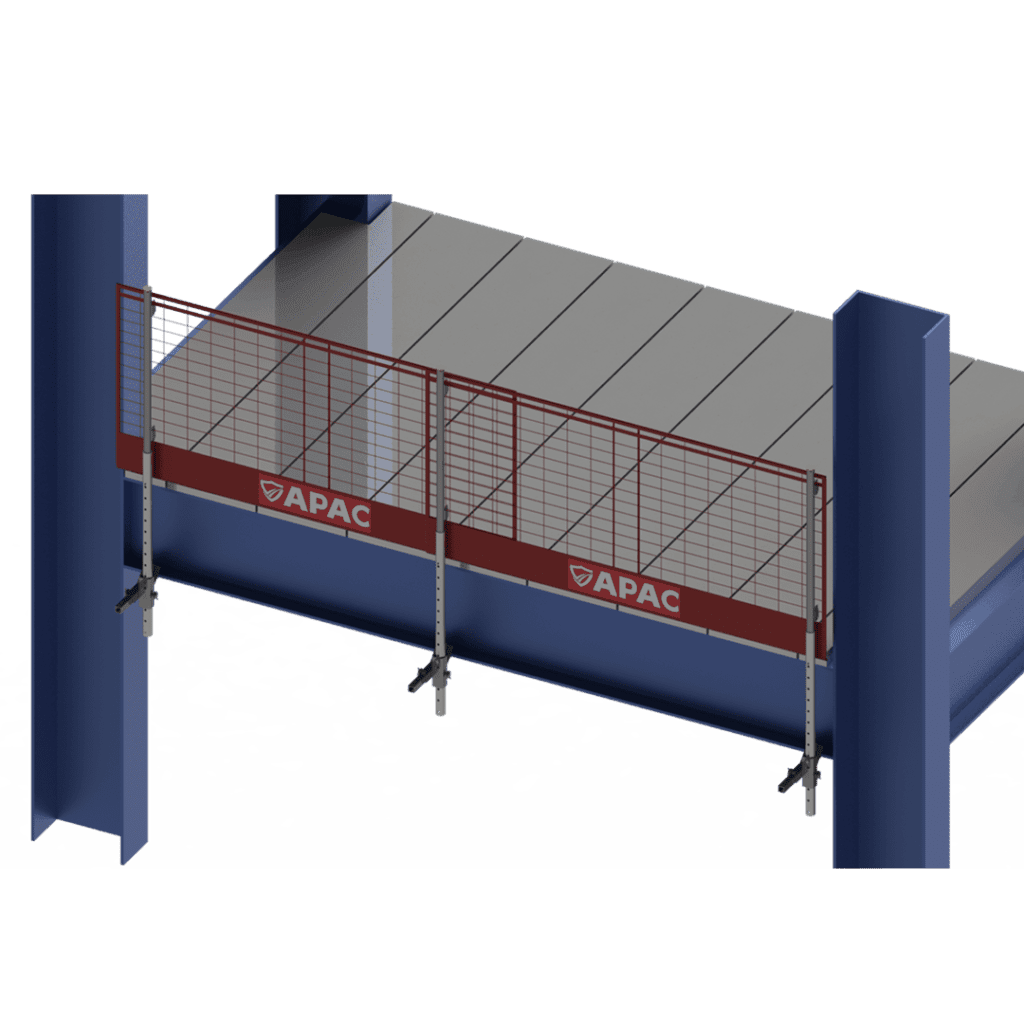

APAC has engaged in edge protection systems since 2014, our edge protection system is suitable for concrete structures, steel structures, frame structures, formwork, stairway, etc.

We place a high value on quality assurance in our business. Keeping quality control at the top of our priorities ensures the highest quality in all products we deliver. Our quality assurance team regularly inspects raw materials, finished goods, incoming materials, and outgoing products to ensure compliance with standards.

The APAC edge protection system for steel structures can accommodate several applications, such as surface-mounted, non-drilling clamps that avoid anchor fixings.

So if you have a steel structure project, and you want to improve the safety condition of the worksite for your workers. APAC is your best choice. We can supply more competitive prices with exceptional products than your local market.

We are also committed to providing excellent customer service. You can reach us by phone or email, and we will always respond within 24 hours.

Steel Structure Edge Protection:

Fast installation

Where possible, the APAC edge protection system can be installed at ground level before the erection of the steel frame, thus significantly reducing the risk of working at height.

- For the I-beam Facade Bracket system for the steel structure edge protection, the fixing component is an i-beam facade bracket anchored to the steel column’s edge.

- For the steel structure I-beam facade bracket system, the steel sections should be checked to ensure that the pre-drilled holes are to the correct spacings before securely fixing the components.

- Positional (i.e., vertical) adjustments can be made before attachment to the steel structure frame. Ensure that the minimum gap is left between the final steel structure work surface level and the bottom of the obstruction, eliminating the need to reposition the system at a later stage as much as possible.

Even our clients are from different countries, we ensure you can use our systems for your steel structure project without any concerns. Because all the APAC edge protection systems strictly conform to EN 13374, Class A, Class B, AS/NZS 4994.1 , AS/NZS 1170, OHSA 1926.502.

We are delighted to offer you the opportunity to download our latest catalog. It contains comprehensive information about our products. Whether you are a prospective customer or a business partner, this catalog will provide you with valuable insights into our offerings.

APAC Edge Protection Systems Catalog

However, if you require more in-depth technical information, we recommend visiting our website. There, you can access detailed datasheets for each product, providing you with a comprehensive understanding of their technical specifications, performance metrics, and compatibility details.

surface treatment for you

All of our metal products undergo surface treatment before shipping in order to achieve color and corrosion resistance.

The most common treatment was powder coating and zinc galvanizing. We give pre-treatment of metal prior to treatment, to ensure the coating is durable and long-lasting.

- Powder-coated – Also known as electrostatic powder coating, is a surface treatment method in which plastic powder is sprayed on the parts to increase the luster of the mesh barrier so that a protective coating is attached to the surface.

- Hot-Dip Galvanized – Steel immerses in a molten zinc bath to create durable and tough zinc alloy layers. It provides maximum corrosion protection for steel when used outdoors.