First-Rated Ringlock Scaffold Exporting Globally Over 10 Years

APAC is a pioneering ringlock scaffolding company that supplies a wide range of ringlock scaffolding system. We guarantee quality and services, catering to brand owners, wholesalers, and distributors overseas.

- High load-bearing capacity: makes it ideal for heavy-duty construction projects.

- Flexibility: it can be easily adjusted to fit different heights and shapes of buildings.

- Cost-effective: due to its modular design, llows it to be reused on multiple projects.

factory direct

Strictly comply with standard AS/NZS 1576 and EN 12810, EN 12811.

EXPERTISE IN SCAFFOLDING

Engaged in Ringlock Scaffolding manufacturing for over 10 years.

oem&odm service

Provide full OEM services, quickly expanding your business.

door to door service

Over 100+ Parts.

More Than 30 Countries.

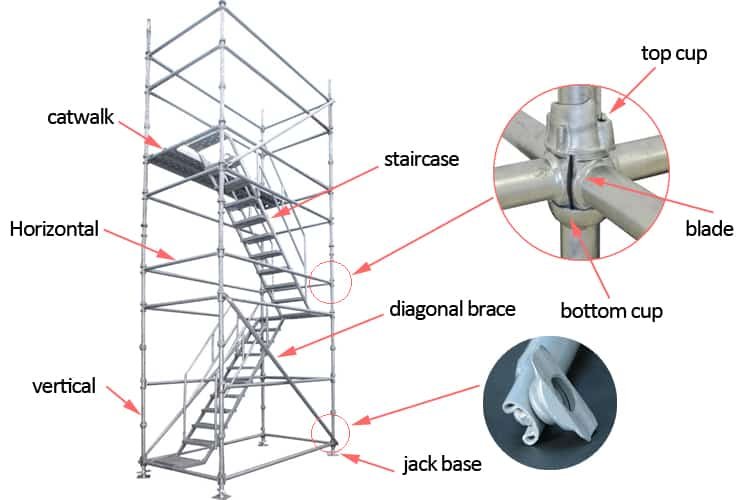

RINGLOCK SCAFFOLD COMPONENTS FOR SALE

Ringlock Scaffolding is a modular scaffolding system for industrial and construction applications.

Compared to the traditional scaffolding system, it has the characteristics of being easy to install, long service life, saving labor, and cost-saving, so ringlock scaffolding is an economic solution for you.

MORE DETAILS ABOUT APAC RINGLOCK SCAFFOLDING

APAC is a leading ringlock scaffolding manufacturer in China. APAC ringlock scaffolding is widely used for various industrial and construction applications.

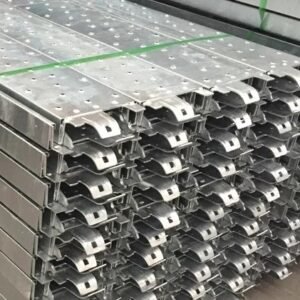

APAC can supply premium grade ringlock scaffolding components in small MOQ. From vertical standards and steel planks to diagonals, we have it all at a great price. Different surface treatments can be chosen for your demands.

Throughout the manufacturing process, APAC keeps a watchful eye on every step, from the inquiry to delivery. To be your trustworthy manufacturer & supplier of Ringlock scaffolding systems in China, we wish to deliver the value of excellent Chinese products and quality to stand the test of time.

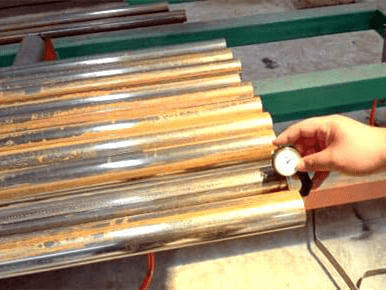

Raw Material Control

In order to let the materials meet the standard of EN10024, before producing, all APAC’s raw materials will have the chemical and physical test.

Metal Physical Test Equipment Wall Thickness Test

Welding Quality Control

APAC Scaffolding gears are welded by experienced and skilled welders or automatic welding machine result in a good quality of the welding surface and have very good penetration of the weldings.

Automatic Welding Welding Quality

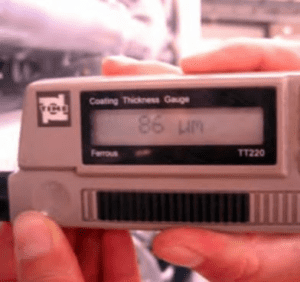

Galvanization Quality

APAC APAC Scaffolding products have reached a high standard of the galvanization, the thickness of the ZINC can be 86 um, and even more.

High Quality Galvanization Thickness of the Galvanization

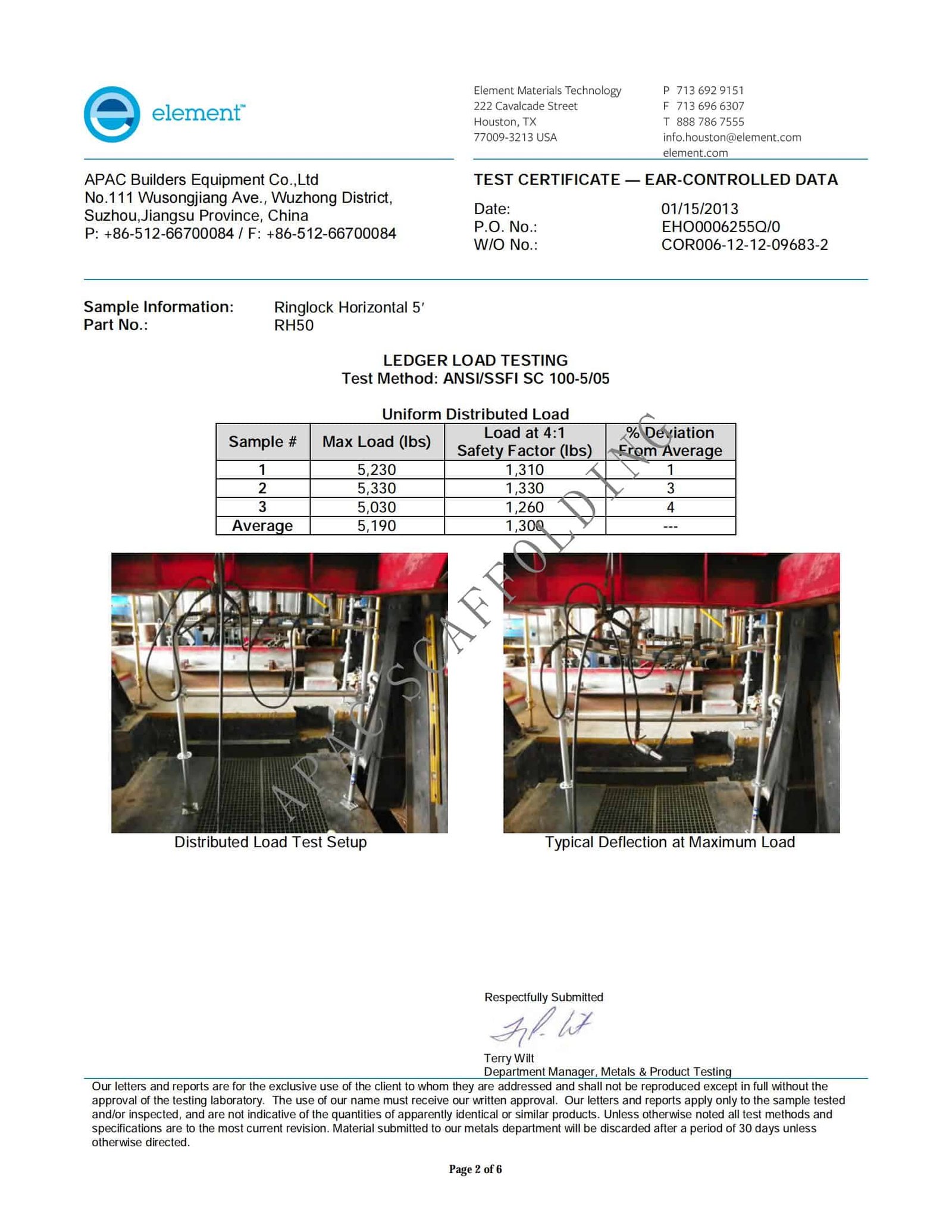

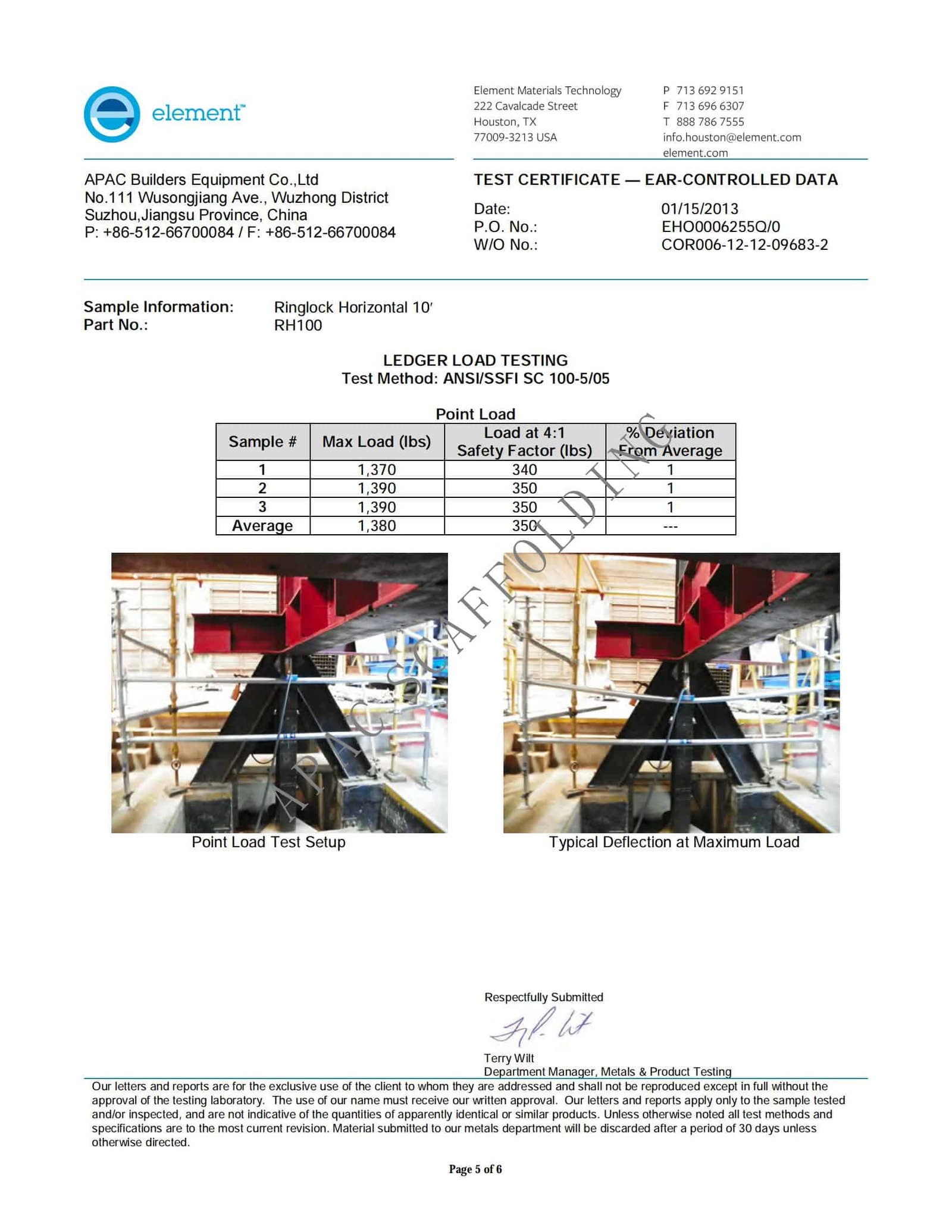

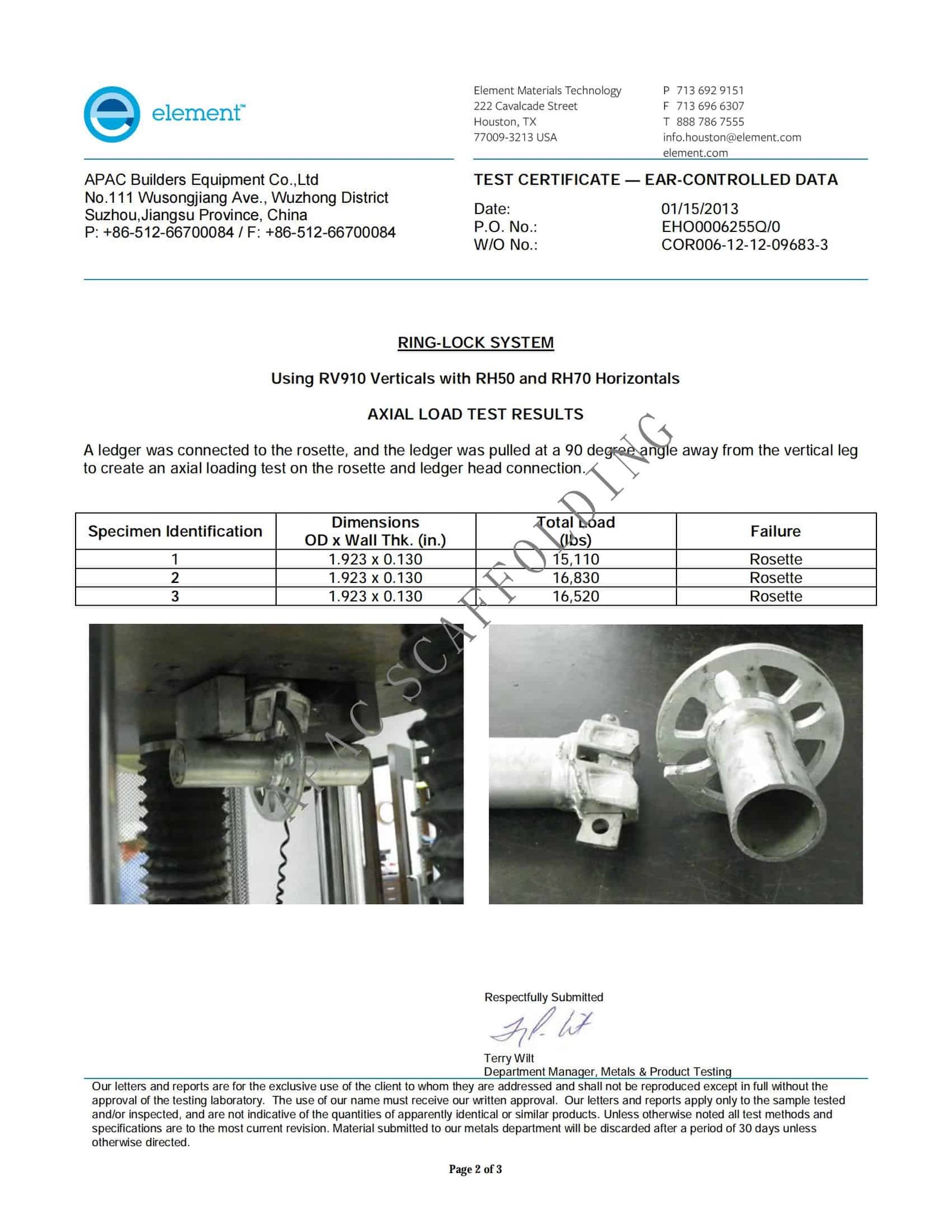

Products In–house Testing

The standard, ledger, screw jack, and plank can be tested before shipment and customer will get the in-house testing certificate. This is very important for the safety of the project.

Plank Loading Test Screw Jack Test

IN APAC, QUALITY IS NOT BOASTFUL BUT CORNERSTONE.

Why you should choose apac

Excellent Support

Professional Technical Team can provide solutions for your construction projects.

Quality Control

Including steel grade testing, dimensional inspection, and weld line testing, etc

Quality Assurance

APAC scaffolding is made of high-quality Q235 or Q355 grade steel.

After-sale Service

Active and dedicated team handle your project in every step.

Competitive price

5 manufacture bases, over 20,000 square meters of factory space

Fast delivery

Extensive experience and expertise in handling and transporting goods.

APAC Faq Guide

As a leading manufacturer, we always receive several questions from our clients all over the world.

Therefore we prepared this beginner’s guide on ringlock scaffolding. If you need any specific information, you are always welcome to send us an inquiry.

1.Can you provide sample?Is it free or extra ?

Yes, we could offer the sample if it’s in stock. But you need to pay the cost of freight.

2.How long can i receive the products?

It’s according to the quantity of your order. About 2-4 weeks after your payment.

3.What kind of payment can I take?

You can make the payment to our bank account, 30% deposit in advance, 70% upon sending the copy of Bill of Lading. Bulk order can be negotiable according to the order status.

4.What materials are used to manufacture Ringlock Scaffolding?

The ringlock scaffolding consists of a tube, plate, collar, and planks. The tube is made of aluminum or steel.

The used steel grade is hot rolled steel. If the construction area has overhead cables, a fiberglass wound tube in a polyester matrix or nylon can be used.

Aluminum alloy is used in ringlock scaffolding. They are three times lighter than steel and highly durable.

For the board you can use steel, aluminum, or wood planks. You can choose one according to your project’s requirements.

5.How Easy Is Your Ringlock Scaffolding System to Assemble?

We can tell many advantages of using a ringlock scaffolding system. But effortless assembling is the most important of all of them.

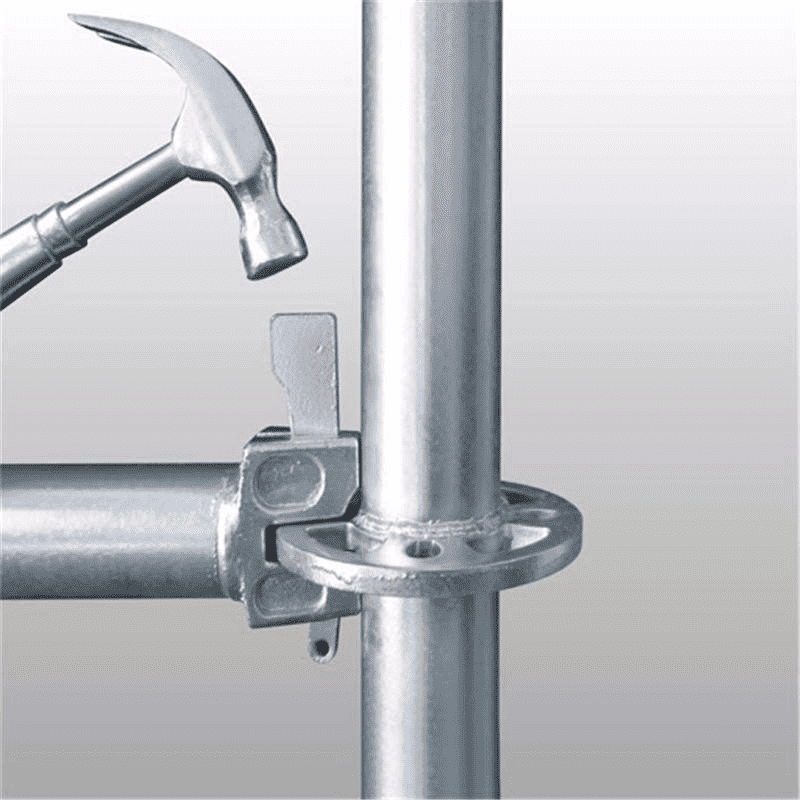

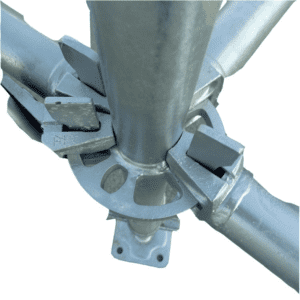

This system consists of three main parts – Rosette, Base collar, and wedge pin. Vertical and horizontal braces are used for linking. Here are the steps for assembling ringlock scaffolding:

- First, the base plates are placed on the ground or surface.

- Then the vertical braces are mounted.

- The horizontal braces are placed between the vertical elements in order to lock the locking mechanism.

- The next phase is to mount other horizontal braces on the locked frame.

- Then vertical braces are mounted by using the upper adjustment shafts to build the upper structure of the system.

Figure 9 – Only hammer is enough to assemble ringlock scaffolding

Assembling ringlock scaffolding is very easy and less expensive. It demands less labor cost and no additional tools. You can set up the entire structure with just one tool – a hammer.

We have demonstrated the assembly process of ringlock scaffolding in the following video

6.What are the benefits of Ringlock Scaffolding compared to Kwikstage Scaffolding?

Both scaffolding systems are made of prefabricated components with specific functionalities. These scaffolding systems are manufactured with high-strength galvanized steel.

The most significant difference between the two lies in the way they are connected.

Figure-10-Ringlock Scaffolding connection

Figure-11 Kwikstage Scaffolding connection

Ringlock scaffolding comes with a unique rosette-type central connector, which can be connected to 8 components. This connector allows ringlock scaffolding to exhibit complex geometries.

Kwikstage scaffolding welds 4 “V” iron plates on the high tensile steel tube as the connection point for standards.

Although Ringlock scaffolding and Kwikstage scaffolding are widely used in the construction industry, Ringlock scaffolding has some advantages over Kwikstage scaffolding. Let’s look at some of the key differences.

- Surface treatment:Ringlock scaffolding is hot-dip galvanized. Kwikstage is normally powder-coated. On the other hand, Kwikstage scaffolding may be refurbished with paint hiding rust, corrosion and traceability.

- Load-handling strength: Ringlock scaffolding has more components to share the pressure resulting in a more stable structure, and the service life is also pretty high. From this point of view,Kwikstage scaffolding is not as durable as ringlock scaffolding.

- Time advantage: Layher Allround scaffolding is a type of Ringlock scaffolding. Back in 2010, Layher already did a comparative test of the installation.

The test results showed that the erection time of Ringlock scaffolding can save over 50% than Kwikstage scaffolding for the same size and height of the assigned structure.

7.How about price? Can i have a discount for the first order?

We are factory direct. It is certainly we do quote for the best price we can do.

If you want to add quantity, we could reduce the price as well to the extent that it afforded us an additional economy of scale. We can accept a lower margin if we do a larger job.

As everyone knows, price is usually not the single most important factor in a purchasing decision. It is one of many factors that determine how much value a product or service has to a customer.

If you only insist to chasing “lower price”, then you may get:

Maybe there are hidden pitfalls such as quality, service, and so on behind the “lower price”.

Pls trust the quotation we would give you, it is professional because of our high level of expertise in handling scaffolding equipment requirements overseas.

8.What is your after sale service?

Our products are manufactured strictly according to international standard, and we take a test on every step before delivered out.

APAC Ringlock Scaffolding have an extended warranty of 2 years post purchase date against manufacturer defects and machine failure. Warranty does not cover light surface rust, or damaged due to negligence or misuse. We are happy to replace or pay compensation faulty goods within their period.

9.What is the general lifespan of Hot-dip galvanized Ringlock Scaffolding?

Hot-dip galvanized steel comes with strong protective zinc. This process makes steel corrosion-resistant to ensure a longer life span. Hot-dip galvanized steel can last as long as 50 years. But as ringlock scaffolding is made for bearing the weight of construction workers and their tools, they don’t survive that much.

But still, the life span of ringlock scaffolding is quite astonishing. Ringlock scaffolding can survive more than 20 years.

Apart from a longer lifespan, the hot-dip galvanization process has another advantage. Hot-dip galvanizing coating is self-maintaining. Therefore, the maintenance cost of ringlock scaffolding is extremely low.

10.What Is The OSHA Safety Guideline Before Disassembling Ringlock Scaffolding?

OHSA has some specific safety guides for ringlock scaffolding. They can be categorized in multiple sectors:

Capacity requirements

- The scaffold must be capable of bearing four times the recommended weight.

- Designed by a certified person.

- Only rated load should be placed

- Must be built with construction-grade lumber.

Construction Safety Requirements

- The platform should be fully planked and decked. The space between uprights and platforms should not exceed 25 cm.

- If the side brackets create a wider opening between uprights and platforms, the space should not exceed 24.1 cm.

Scaffold planking

- Scaffold planks of ringlock scaffolding must be able to bear four times the intended load.

- The fabricated planks, platforms should be used following the manufacturer’s instructions.

11.Does APAC provide technical support for the Ringlock Scaffolding System?

Yes, as a leading scaffolding system manufacturer in China, we have expertise in ringlock scaffolding. Ringlock scaffolding is a relatively new product. In APAC, we have the best experts from China and manufacture using one of the best factories in China.

Here are some factors why we are considered as one of the leading ringlock scaffolding manufacturers in China:

- We are equipped with the best designers, engineers, and workers.

- We ensure the proper metal management in the manufacturing steps.

- Our products are produced by TS EN 10219-1 certification and mechanical tests.

- According to EN ISO 3834-3 standards, we use gas metal arc welding.

- We always follow the rules and regulations applied by OSHA.

Scaffolding is not just a construction tool. Workers’ life depends on the quality of the scaffolding system. Ringlock scaffolding is safe, and that’s why contractors prefer this system over other scaffolding. We maintain all the safety measures so that contractors can have full trust in us, so do the workers.

If you have any queries or any project in your mind, send us an inquiry. A dedicated expert on Ringlock scaffolding will contact you shortly.

Still not finding your needed Ringlock Scaffolding Products?

Contact our experts for professional & cost-effective solutions.

RELATED products

In addition to Ringlock scaffolding, APAC also offers other types of scaffolding. For any inquiries or further information, please feel free to reach out to us. Let’s work together to build a safer construction industry!