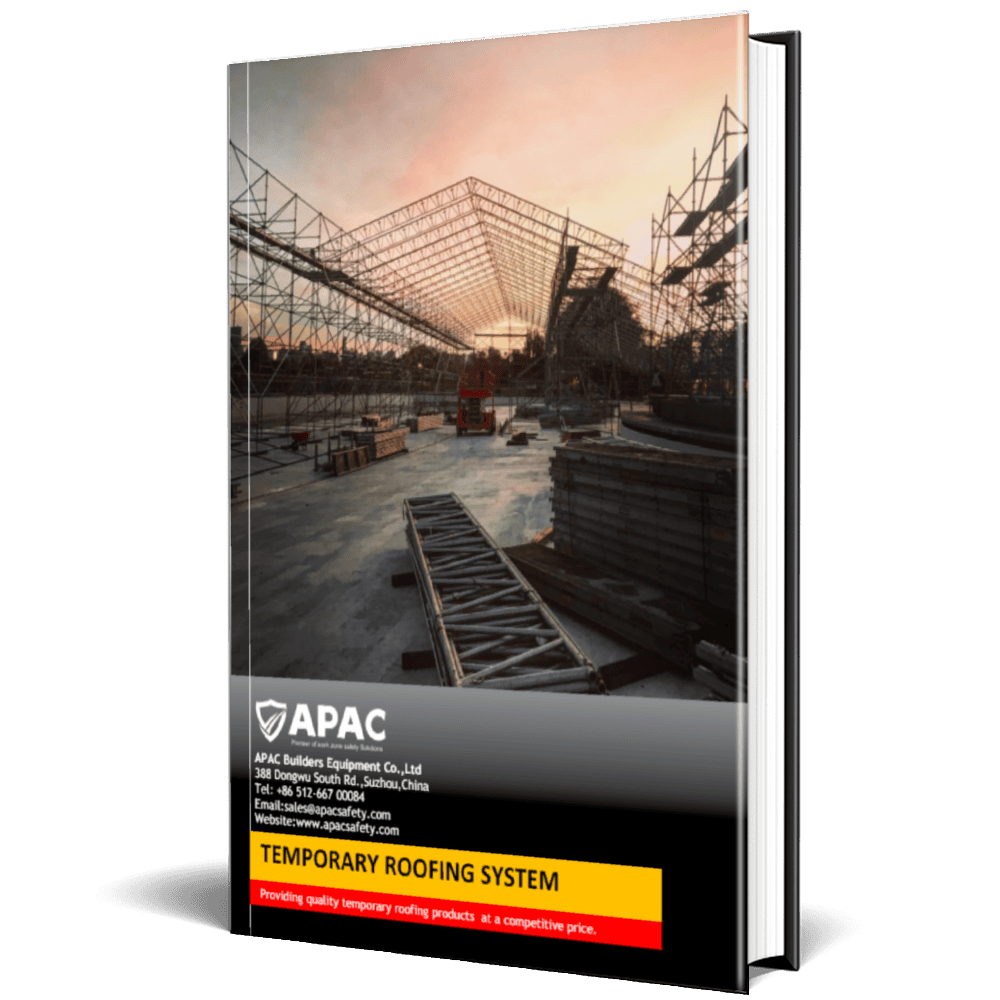

Keder Roof

- Fully compatible with common modular scaffolds, deploy the same roof kit across different site setups without redesigning everything.

- Engineered for small to large covers, with layouts that can span beyond 40m when the support scaffold and bracing strategy.

- Lightweight aluminium build, Low self-weight components are easier to move and assemble on site, speeding up build/strike cycles.

what is Keder roof

Keder Roof, also known as a temporary roof system or weather protection system, offers unparalleled efficiency and versatility for various construction and industrial applications. Made from lightweight aluminum materials, the Keder Roof system is designed to be both durable and easy to install.

The Keder is a roof structure consisting of aluminum trusses. The roof itself is made of PVC tarpaulin and is mounted into Keder rails on the trusses. The finished result is always tight, neat, and durable.

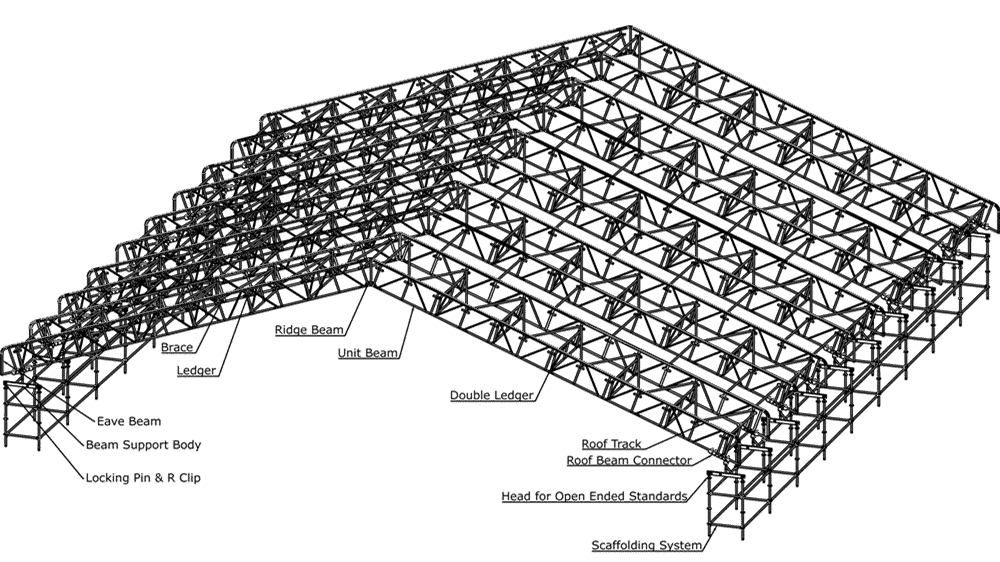

Components of APAC Keder Roof

APAC is the China Leader supplier for the keder roof, we can provide complete solutions for the kede roof system. The products have already been successfully sent to Europe, North America, Australia, etc.

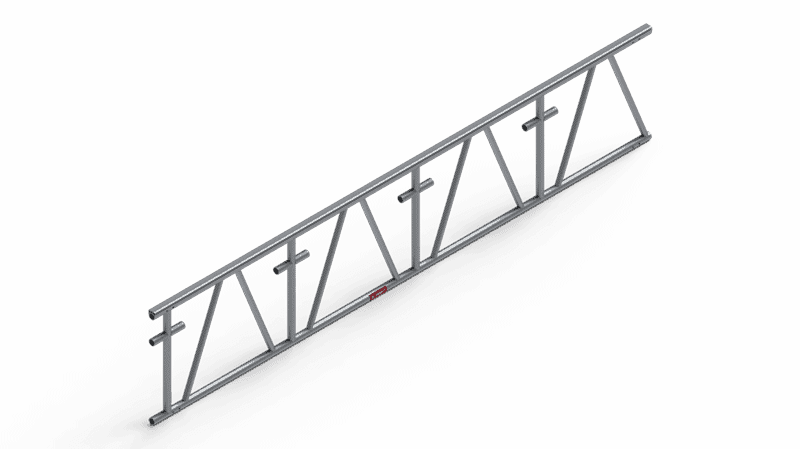

Ridge Beam

The Ridge Beams help to form an 18 degree duo pitch roof depending on the requirements of the project.

Unit Beam

Manufactured from EN AW 6082 T6 Alloy, these form the main structural member of the APA keder roof.

Beam Spigot

Four holes spigot used in conjunction differing lengths of Unit Beams, Ridge Beams and Eaves Beams to one another.

quick release pins

12mm quick release pins are used in conjunction with the four holes Beam Spigot, to connect differing lengths of APAC Beams.

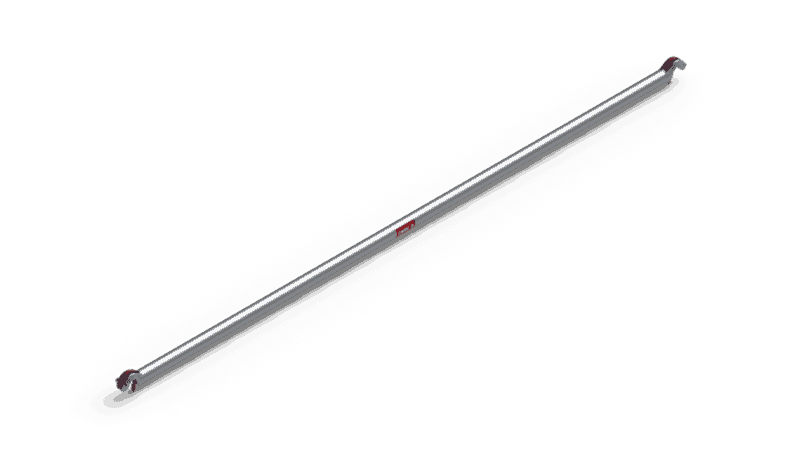

Horizontal Brace

Used to connect two adjacent beam lines (trusses) together, attached to the top and bottom chords of the beams.

Diagonal Brace

Attached diagonally between the top of the vertical posts of the Unit beams at the position of the Brace Frames.

Ratchet Strap

2″ (50mm)width ratchet straps secure and tension the roof sheeting to the supporting structure at the eaves

Double Horizontal Brace

Used to connect two adjacent beam lines (trusses) together, attached to the vertical posts of the beams using a special claw casting.

Eave Spigot

Positioned within the top chord of the Unit Beam at the eaves and fixed in position with a Quick Release Pin.

Sheet Pull Bar Assembly

Inserted through the Sheet Tension Bar at one side of the sheet, guiding the sheet smoothly over the roof.

Sheet Tension Tube

Special length tubes to be used in the ends of each Roof Sheet to enable installation and tensioning.

Sheet End Coupler

Fixed the coupler to the bottom chord of the beam and make sure the PVC sheet be tensioned tightly.

keder roof sheeting

APAC Keder roofing sheet is a temporary roof covering that provides excellent weather protection.

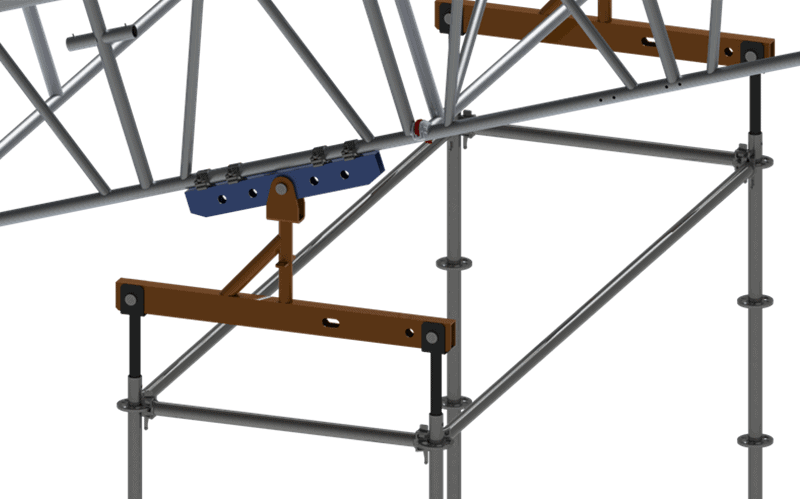

Moveable Rail System

The moveable roof rail system consists of Rail Beam, wheels, wheels connector and roof beam connector.

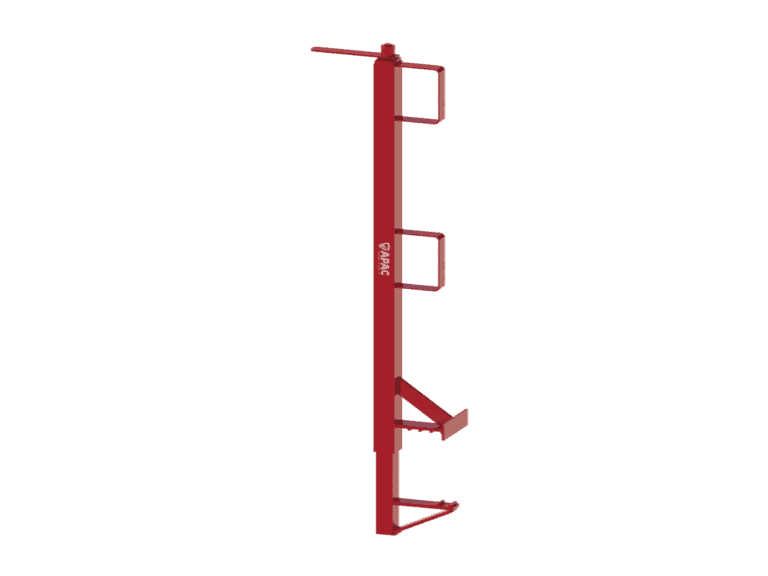

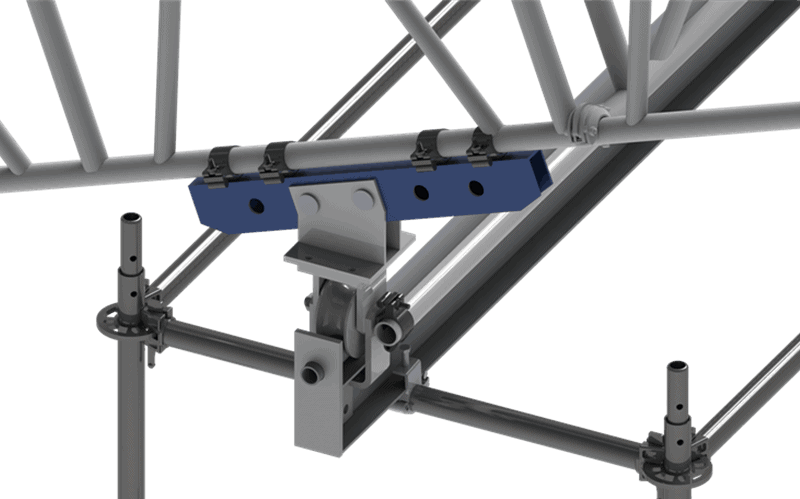

Fixed Beam Support System

The fixed beam support system consists of U head for open ended scaffold, Beam Support Unit, and beam connector.

Professional Keder Roof to Support Your Business

The system’s smart joints and aluminum roof components significantly reduce labor requirements, streamlining the setup process. Components are pre-assembled on the ground and can be swiftly installed using a crane, saving both time and resources. This system is perfect for protecting work areas from adverse weather conditions, ensuring a tight, neat, and durable finish.

All APAC Keder roofs are designed to allow simple, clear, and efficient assembly, and the lightweight aluminum material makes heavy manual labor unnecessary.

Part dimensions designed with practical applications in mind make it unnecessary to take up valuable storage space.

The APAC Keder roof is particularly suitable for short-term requirements. Thanks to its versatile system technology and short assembly times, APAC keder roof is also a very economical and very attractive total solution for lightweight assembly.

APAC keder roof has many areas of application, from the implementation of roofs and timber roofs and coverings during additions, weather protection of new structures or renovation work on highways and bridges, to a variety of events and normal working applications.

Why Choose APAC Keder Roof

Compatible with multiple scaffolding systems, APAC Keder Roof supports wide spans up to 40 m with lightweight, corrosion-resistant aluminium trusses—and we back it up with project-specific design + 3D visualisation to confirm layout and BOM before delivery.

Scaffold Compatibility (Layher-ready, multi-system fit)

APAC Keder Roof is designed to interface cleanly with multiple scaffolding platforms—including all Layher systems—so your roof layout follows your scaffold grid, not the other way around. This reduces interface surprises and keeps RFQ scope clear.

Compatible with all Layher scaffolding systems + other common scaffold setups

Standard truss bay options: 2.57 m and 3.07 m

Common span compatibility: 7’ (2.1 m) and 10’ (3.05 m)

Custom truss spacing available to match your site bay size

Wide Span + Lightweight Aluminium (up to 40 m)

For projects where coverage width is the bottleneck, APAC Keder Roof can be engineered to reach up to 40 m roof width. The aluminium truss structure keeps self-weight low, improves handling, and naturally resists corrosion for long-term outdoor use.

Engineered roof width: up to 40 m (project-dependent)

Standard builds: up to 18 m can be installed without a crane

>18 m spans require additional structural design

Aluminium = corrosion-resistant (no rust) + lower self-weight for faster handling

Snow load support available (must be specified and designed separately)

Project Design + 3D Visualisation

APAC doesn’t treat a Keder roof as “parts you figure out on site.” We turn your site inputs into a defined roof configuration—so the roof form, interfaces, truss spacing, and key supports are aligned before production. With 3D visualisation, your team can review the build logic early, reduce coordination gaps between scaffold, temporary works, and procurement, and lock a BOM that’s easier to receive, check, and install.

Project-specific design support based on your span / height / bay size / scaffold type

3D visualisation for roof form: double-pitch / mono-pitch / arch (polygonal barrel)

Layout clarity improves internal approval and site handover

Planning support with material & loading capacity tables for quicker decision-making

Trusted by contractors worldwide

Applications of the Keder Roof System

The APAC Keder Roof system is incredibly versatile and appropriate for a number of applications.

Refurbishment & reroofing — keep trades working in a dry zone.

Industrial shutdowns — protect critical maintenance windows from weather delays.

Scaffold access & working platforms — cover walkways and workfaces for safer movement.

Residential & commercial construction — reduce material damage and re-handling in rain.

Infrastructure & shipyard maintenance — reliable cover for outdoor repair works.

Event / stage areas — clean appearance + weather protection where aesthetics matter.

Keder Roof | The Ultimate FAQ Guide

Q1 Is the roof fully waterproof?

The PVC keder sheet slides into the keder rail to form a tight, continuous connection, creating a rainproof cover. Like most temporary roofs, condensation and dripping may occur depending on temperature and humidity.

Q2 Is the system compatible with my scaffolding?

APAC Keder Roof can be designed to integrate with common systems such as ringlock, tube & clamp, and modular scaffolds. Send your bay size and scaffold type—we’ll confirm the interface and produce a matched BOM.

Q3 Can it handle wind and snow loads?

Yes, but wind exposure and snow load must be specified early so the bracing and tie strategy can be engineered accordingly. The final capability is project-dependent and should follow your temporary works requirements.

Q4 Can the Keder Roof be installed without a crane?

Yes, many standard-width projects can be built without a crane thanks to the lightweight aluminium components. Final method depends on working height, access, and the build sequence required by your site.

Q5 How fast is assembly on site?

Yes, but wind exposure and snow load must be specified early so the bracing and tie strategy can be engineered accordingly. The final capability is project-dependent and should follow your temporary works requirements.