RINGLOCK LEDGER

The Ringlock Ledger is a critical horizontal element in the Ringlock scaffolding system, designed to provide robust support and safety on construction sites.

Ledgers are connected to the vertical Standards using the cast end with the captive wedge, which can be used as horizontal support for planks or act as guardrail edge protection. This connection is extremely strong and prevents the possibility of loose components.

APAC has been offering Hot Dipped Galvanized Ringlock Ledger Used For Construction Scaffolding for over 10 years. Our Ring lock System strictly conforms to EN 12810/EN12811, ANSI/SSFI SC100-5/05, AS/NZS 1576 etc standard.

Q235 Hot-Dipped Galvanized Ringlock Ledger

Customizable cast steel ringlock ledger head

ringlock double ledger / truss ledger

The ledger is laser-welded at both ends to laser plugs, which are then inserted into the rosettes, forming a secure and stable connection. This system is designed to provide maximum stability and safety for the entire scaffolding structure, making it a reliable choice for various construction projects.

APAC Ringlock Scaffolding System with hot dip galvanized surface treatment is easy to install & disassemble. Compared to steel tubes with couplers, ringlock scaffold system is 2~3 times the installation & dismantling efficiency higher than the cuplock scaffolding system, but only with half steel usage and 75% investment cost.

Our Ringlock system with 200 KN high loading bearing capacity is buyers’ safe & professional choice, providing the users with higher safety & benefits.

Learn more about the Scaffold Ledger

Defination And Bascis

Why choose APAC Ringlock Scaffolding?

Focus on construction

We supply ringlock scaffolding to commercial client. Whether you are a large construction company, a distrbuter or wholesaler, we have the right products to meet your projects needs.

Driven by quality

Committed to keep site worker's healthy & safe, We follow a strict quality inspection procedure which means we are always prepared for any order no matter how big or small.

More than products

We have lots of years of experience in the scaffolding industry, this means we always conduct our work in a professional manner and give our customers the solutions they need.

exceptional reputation

We are proud of our exceptional reputation for service and price. As a leading Chinese worksite safety products supplier, customer satisfaction is at the heart of everything we do.

Ringlock ledgers Supplied by APAC

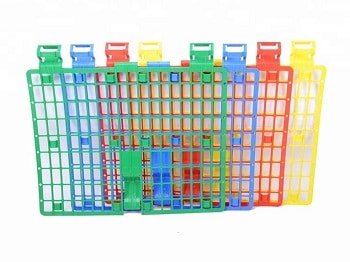

APAC provides scaffolding to Unite States and Canada. We also provide scaffolding to Singapore, New Zealand, Australia, the size of the ledger normally is metric size, such as 1.4m, 1.57m, 2.57m. etc.

There are several different types of ledger heads for your choice. We can also produce your design if the CAD drawing or sample is offered.

ringlock scaffolding in construction

The ringlock Scaffolding system is popularly used in construction, formwork support, Facade scaffolding, bridge & tunnel, Stairway access, mobile work scaffolding tower, trenches and emergency structure, stage construction etc. and it’s welcomed by construction & decoration companies, petrochemical industry, media & advertising companies and other users.

ledger/horizontal Wholesale Supplier

APAC manufactures the high-quality Ringlock scaffolding ledger, the surface treatment is hot-dip galvanized. Painted or powder-coated Ringlock scaffolding Standard is also workable based on customer’s requirements.

With APAC, you will have good quality welding Ringlock scaffolding Standard, which is based on EN 1090-1 and ISO 3834-2 standard.

If your project just needs our Ringlock scaffolding Standard, please don’t hesitate to contact us. Free samples and competitive price will be afforded.

Boost Your Business with APAC ringlock LEDGER

With years of expertise in the scaffolding sector, APAC offers specialized services and solutions to satisfy your construction demands.

Get in touch with APAC right now to learn more or to get a quote, and find out how our scaffolding solutions might help your upcoming project.

FAQs

Precision casting and sand casting are two ways in the casting industry, each has its own advantages and disadvantages, the following is an introduction to the differences between precision casting and sand casting.

1) Precision casting.

First make wax parts is the end of the casting, and then hang slurry on the wax mold, sticky sand, so that it forms a strong shell on the outside of the wax parts, the next heating, the wax drain, pouring steel or aluminum water into the empty shell, cool down and vibrate the shell, you can get the desired casting. High quality of the external appearance of fine castings and precise dimensions.

2)Sand casting.

Sand casting, also known as sand turning, first made of wood to make the casting, usually the material selected is wood, but also useful metal type, the wood type buried in the sand, and then remove the wood type, so that the sand type into a cavity. Pour the steel out of the cavity, after cooling is the desired style of casting. Sand castings are poor in external quality, the size is not as accurate as fine casting, but the cost is lower than fine casting.

If the batch is very large, it is better to accept die-casting mold, high output, low cost per piece; compared with precision casting mold and sand casting mold, die-casting mold cost is higher.