Introduction

Heavy-duty shoring posts are essential tools for any construction project that involves excavation or trenching. These posts are used to support the weight of the surrounding soil and prevent it from collapsing inward, providing a safe and stable environment for workers. In this ultimate guide, we will explore everything you need to know about heavy-duty shoring posts, including their uses, benefits, and key features.

First, we will discuss the different features of heavy-duty shoring posts available on the market and how to choose the right one for your specific needs. We will also cover applications for shoring posts. Additionally, we will provide tips for maintaining your heavy-duty shoring posts and extending their lifespan.

This guide will equip you with the knowledge and skills necessary to use heavy-duty shoring posts safely and effectively.

What is a Heavy-duty Shoring Post?

A heavy-duty shoring post is essentially a vertical support used to temporarily bear the load of formwork, slabs, beams, or other structural components during construction. Think of it as the adjustable backbone that props up your project while concrete sets and gains strength.

Now, you might be wondering: “Aren’t all props the same?” Not quite. Here’s the difference:

Light-duty props: Designed for smaller loads, usually in residential or low-rise works. They’re economical but limited in capacity (often under 20 kN).

Heavy-duty props: Engineered for large-scale projects with higher load requirements, typically ranging from 20 kN up to 50 kN or more. These are the ones you’ll see on mega-projects like airports or highway bridges.

Industry names vary by region:

In the UK and Australia, you’ll hear Acrow Props.

In the US, they’re often called jack posts.

Elsewhere, terms like telescopic props or adjustable props are common.

But at the end of the day, no matter what you call them, they serve one core purpose: keeping your structure stable, safe, and upright until it can support itself.

Key Components and Design Features Of Heavy-duty Shoring Post

If you’ve ever handled a heavy-duty shoring post, you’ll know it’s more than “just a steel tube.” Let’s break down the components:

Outer and Inner Tube Construction

Usually made from Q235 or Q355 high-strength steel.

The outer tube is the fixed element; the inner tube slides inside to adjust length.

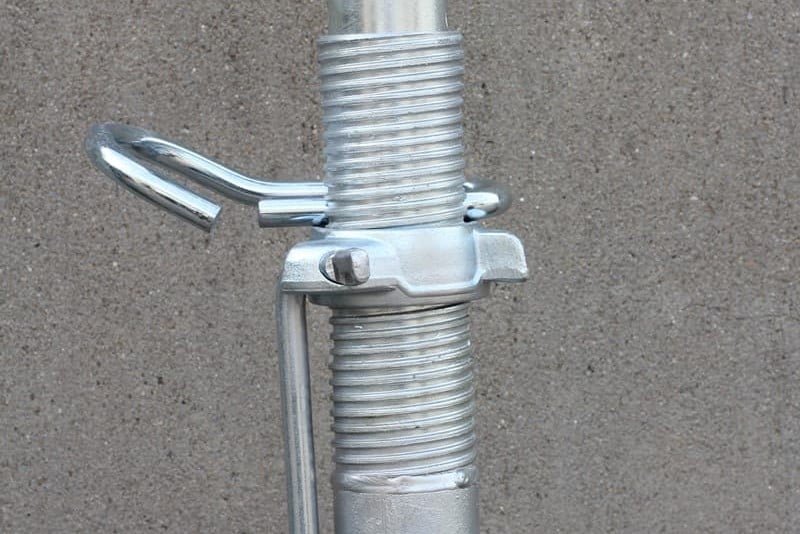

Thickness matters: a 3.0–4.0 mm wall can handle far more load than a 2.0 mm one.Adjustable Nuts and Handles

The nut allows for fine-tuned adjustments to height.

Good props feature ergonomic handles so workers can easily tighten them without injury.Base Plates and Top Plates

Distribute load evenly to prevent sinking or punching into slabs.

Can be flat, cupped, or even U-shaped, depending on application.Surface Finish: Galvanized vs Powder-Coated

Hot-dip galvanized: Best for durability and corrosion resistance, especially outdoors.

Powder-coated: Cost-effective and available in colors (often used for branding).Safety Locking Systems

Anti-slip pins and double locking features prevent accidental collapse.

These are not optional — they’re lifesavers on-site.

Load Capacity

Heavy-duty shoring posts are designed to carry a significant amount of weight, ranging from a few hundred pounds to several tons. The load capacity of the shoring posts must be determined based on the weight of the structure that needs support.

Typical Ranges:

- Light-duty props: 10–20 kN.

- Heavy-duty props: 20–50+ kN depending on length and tube thickness.

Adjustability

One of the essential features of heavy-duty shoring posts is their adjustability. These posts can be extended or retracted to fit different heights and angles, making them versatile and adaptable to different construction projects.

Safety Features

Heavy-duty shoring posts come equipped with safety features such as locking mechanisms, base plates, and stabilizers that ensure stability and prevent accidents. These features are critical in ensuring the safety of workers and preventing the collapse of temporary structures.

Shoring Posts vs Other Support Systems

When should you use shoring posts, and when should you consider alternatives?

Vs. Scaffolding Frames

Frames are ideal for larger spans and higher heights.

Posts are more flexible and space-efficient for slabs.

Vs. Lightweight Props

Lightweight props save money on small projects.

Heavy-duty props are mandatory for heavy loads or repeated use.

In short: use frames for scale, lightweight props for economy, and heavy-duty props for safety-critical projects.

Applications Of Heavy-duty Shoring Post

One of the most common applications of heavy-duty shoring posts is in supporting structures during construction. The posts are used to provide temporary support for concrete slabs, beams, walls, and other structural elements. This is especially important in cases where the structure is being built in stages, and the weight of the upper levels could cause the lower levels to collapse.

Another application of heavy-duty shoring posts is temporary shoring during renovation or repair work. This is necessary when sections of a building are being renovated or repaired, and the existing structure needs additional support to ensure that it does not collapse. Heavy-duty shoring posts are often used to provide this support and keep workers safe while they carry out their tasks.

Heavy-duty shoring posts are also used in supporting excavations and trenches. They are installed to prevent the sides of the excavation or trench from collapsing, which can cause injury or death to workers. The posts can be used in combination with other equipment, such as trench boxes, to create a safe working environment.

Advantages Of Heavy-duty Shoring Post

- Increased safety on construction sites

One of the primary advantages of using heavy-duty shoring posts on construction sites is increased safety. Construction sites are known for being hazardous environments, and any mistake could lead to serious injury or even death.

With shoring posts in place, the risk of structural failure and collapse is minimized, ensuring that workers can carry out their tasks without fear of accidents. The use of heavy-duty shoring posts provides a solid foundation for the construction process, which ultimately reduces the risk of structural damage.

- The more efficient construction process

In addition to increased safety, the use of heavy-duty shoring posts can also make the construction process more efficient. Shoring posts help to distribute the weight of the materials used during construction, ensuring that they are evenly distributed across the entire structure. This reduces the risk of uneven weight distribution, which can lead to structural failure.

Additionally, heavy-duty shoring posts can be quickly installed and removed, reducing the time required for the construction process.

- Cost-effective solution for temporary support

Another advantage of using heavy-duty shoring posts is cost-effectiveness. Temporary support structures are essential during the construction process, but the cost of building a permanent structure for temporary support can be prohibitive.

Heavy-duty shoring posts offer a cost-effective solution for temporary support, as they are reusable and can be easily transported to other sites. This reduces the cost of constructing temporary support structures and ultimately leads to cost savings for the construction project.

Maintenance And Care Of Heavy-duty Shoring Post

- Regular inspection

Regular inspection is one of the most critical aspects of shoring post-maintenance. Inspect the posts for any visible signs of wear and tear, such as cracks or deformities. Check the locking mechanisms to make sure they are working correctly and inspect the baseplates for damage.

- Cleaning and lubrication

Cleaning and lubrication are also crucial to maintaining heavy-duty shoring posts. Dirt and debris can accumulate on the posts, causing friction and making them more challenging to use. Clean the posts thoroughly using a damp cloth and mild detergent. Lubricate the locking mechanisms with a high-quality lubricant to ensure they work smoothly.

- Replacement of damaged parts

If any parts are damaged, it is essential to replace them promptly. Do not attempt to repair damaged parts as this could compromise the structural integrity of the shoring posts. Replace any damaged parts, including locking mechanisms, baseplates, and hydraulic components, to ensure the shoring posts function correctly.

OSHA regulation and requirement

OSHA (Occupational Safety and Health Administration) has rules and guidelines regarding shoring, including heavy-duty shoring posts, to ensure safety on construction sites.

OSHA standards related to shoring are primarily found in 29 CFR 1926 Subpart K, which covers scaffolds, fall protection, and other construction-related safety issues, as well as in the 1926.705 regulation specifically related to shoring operations.

Here are some key OSHA requirements related to shoring and heavy-duty shoring posts:

Design and Engineering

OSHA requires that any shoring system, including heavy-duty shoring posts, be designed by a qualified engineer when it is used to support more than 20 feet of vertical height or if it is used for a load greater than a standard scaffold can handle.

For heavy-duty shoring, the system must be designed to support the maximum expected loads, including any additional loads from workers, equipment, or other activities occurring on the site.

Inspection and Maintenance

The shoring system, including posts, should be inspected regularly (before and after each use) to ensure that it is functioning as designed and is free from defects, corrosion, or other damage.

Any damaged or defective equipment should be repaired or replaced immediately.

Training

Workers involved in erecting, dismantling, or working near shoring systems must be trained in the proper use and safety procedures. This includes understanding the risks associated with shoring systems and recognizing the signs of structural failure. Or trenching and excavation competent person training to help workers gain more understanding of the site.

It’s important for employers to ensure that the use of shoring systems complies with all relevant OSHA regulations to protect workers from potential injuries or fatalities. Checking local regulations in addition to OSHA’s requirements is also recommended, as some states may have more stringent safety requirements.

FAQs on Heavy-duty Shoring Posts

Q1: How much weight can a heavy-duty shoring post support?

A: Anywhere from 20 kN to 50 kN+, depending on size and material.

Q2: What’s the difference between EN 1065 and non-certified props?

A: EN 1065 props are tested and guaranteed for safety. Non-certified props? You’re gambling.

Q3: How long do shoring posts last on site?

A: With proper maintenance, 5–8 years is common.

Q4: Can shoring posts be reused safely?

A: Absolutely — provided they pass inspection after each use.

Q5: Where to buy heavy-duty shoring posts?

A: Direct from manufacturers or trusted distributors. Always check compliance documents.

Conclusion

The ultimate guide to heavy-duty shoring posts covers various essential aspects related to these critical construction tools. From their features, and applications, to their maintenance, this guide provides a comprehensive overview for anyone working with shoring posts.

The guide emphasizes the importance of selecting the right type of shoring post for the job, understanding their load capacity, and ensuring proper installation to ensure safety and avoid accidents.

Additionally, regular inspection, cleaning, lubrication, and replacement of damaged parts are crucial to maintaining shoring posts’ effectiveness and longevity. By following this guide’s recommendations, you can make sure that your shoring posts perform optimally, ensuring the safety and success of your construction projects.