Introduction

On November 26, 2025, the high-rise fire at Wang Fuk Court in Hong Kong shocked the construction industry. While investigations are ongoing, the rapid vertical spread of the flames has reignited a critical global conversation: Are the temporary materials on our sites—specifically scaffold nets—fueling the fire or fighting it?

Many procurement managers operate under the dangerous misconception that “flame retardant” means “non-combustible.” It does not. As verified by international standards like EN 13501-1 and NFPA 701, true fire-retardant nets are engineered to self-extinguish and prevent molten droplets, buying precious time for evacuation.

This article explores the international classifications and testing standards governing fire-retardant scaffold nets. We will unpack how different countries define flame resistance, what specific performance benchmarks these products must meet, and how buyers can validate supplier claims. Understanding these elements is essential for contractors, project managers, and procurement professionals committed to workplace safety and regulatory compliance.

Fire Retardant Standards by Country

1. China: GB 5725-2025 – Scaffold Nets

The updated Chinese national standard GB 5725-2025 builds upon the 2009 version with a greater emphasis on classification, test transparency, and safety assurance. It continues to serve as the mandatory regulation for construction scaffold nets, including flat, vertical, and canopy configurations, while aligning closer to international norms.

Applicable Products: Scaffold nets for fall protection, debris containment, and pedestrian shielding on active construction sites

Test Method: Enhanced vertical flame test (revised GB/T 5455), now requires testing at three vertical positions on the sample to improve reliability

Updated Performance Requirements:

After-flame time (average of three trials): ≤ 4 seconds

After-glow time: ≤ 4 seconds

Maximum char length: Not to exceed 150 mm (new addition)

Material Scope Expansion: The 2025 revision now explicitly covers synthetic fiber blends (e.g., PE/PVC composites) and mandates separate testing for edge ropes and support cords due to their critical load-bearing function.

Labeling and Compliance: Certified products must now carry standardized compliance labels with traceable batch codes and QR-linkable digital certificates.

These enhancements ensure GB 5725-2025 offers a more transparent, enforceable benchmark for both domestic projects and international buyers sourcing from Chinese manufacturers. to net components including the mesh body, border ropes, and tying cords. All parts must be tested individually to ensure consistent flame-retardant properties.

2. United States: NFPA 701

The NFPA 701 is widely adopted in the U.S. for evaluating the flame propagation of textiles and flexible membranes, including those used in temporary building protection.

- Applicable Materials: Drapes, curtains, tarpaulins, tents, and textile nets

- Testing Methods:

- Test Method 1: For lightweight fabrics under 700 g/m²

- Test Method 2: For heavier materials such as large drapes and vinyl-coated fabrics

- Test Parameters for Method 1:

- After-flame duration must not exceed 2.0 seconds

- Maximum char length defined by material type

- No flaming drips permitted

NFPA 701 compliance is typically confirmed by third-party lab certification and is often required for scaffold netting used in public-facing or indoor construction.

3. United Kingdom: BS 5867-2 (Type B/C)

BS 5867-2:2008 is the UK standard for flammability requirements of fabrics used in curtains and drapes, but it is commonly referenced for scaffold netting due to similar textile composition.

- Scope: Fabrics used in interior or temporary construction applications

- Classification:

- Type A: No specific flame resistance required

- Type B: Self-extinguishes within 2 seconds of flame removal

- Type C: Maintains performance after 12 launderings

- Type B Requirements (most relevant to scaffold nets):

- Flame must extinguish within 2 seconds post ignition

- No flaming debris or excessive char

Although not specifically developed for construction nets, Type B compliance is often cited in UK site safety documentation, especially for temporary sheeting.

4. European Union: EN 13501-1

EN 13501-1:2018 is the European harmonized standard used to classify the reaction to fire performance of construction products, including nets, membranes, and tarpaulins.

- Applies To: All construction materials intended for permanent or temporary installation

- Classification System:

- Main Classes: A1 (non-combustible) to F (highly flammable)

- Smoke Emission (s): s1 (low), s2 (medium), s3 (high)

- Flaming Droplets (d): d0 (none), d1, d2

- Typical Grades for Nets:

- B-s1, d0: Flame-retardant with low smoke and no flaming droplets

- C-s1, d0: Slightly less resistant but acceptable for many applications

EN 13501-1 is mandatory for CE marking in the EU and often required for netting used in public or commercial construction projects.

5. Germany: DIN 4102-1

Though gradually being replaced by EN 13501-1, DIN 4102-1 remains widely respected in Germany for classifying building materials based on fire performance.

- Classification Tiers:

- A1, A2: Non-combustible

- B1: Flame-retardant (Schwerentflammbar)

- B2: Normal flammability

- B3: Easily flammable (not suitable for construction use)

- B1 Classification Criteria:

- Material must first meet B2 requirements

- In flame test, residual length after combustion ≥ 150 mm

- No continued flaming; ignition temp must remain < 200°C

DIN B1 is commonly requested in German public construction tenders. Products are typically certified by recognized institutes like TÜV or MFPA to ensure traceability and compliance.

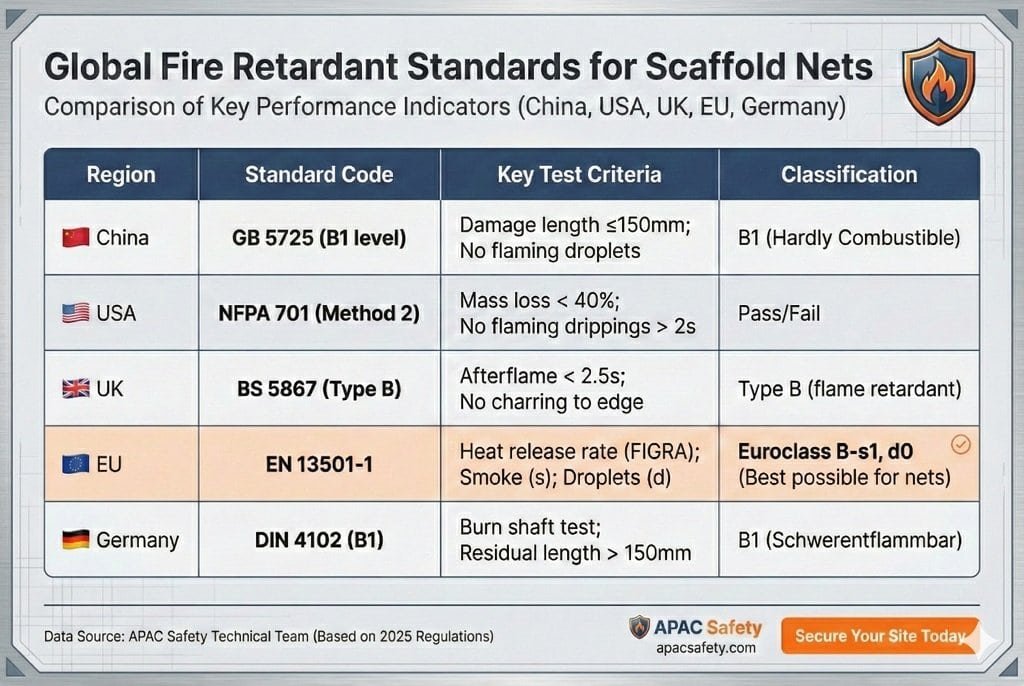

Comparison Table: International Standards at a Glance

Country | Standard | Application Scope | Fire Criteria | Classification |

China | GB 5725-2025 | Construction scaffold nets | After-flame ≤ 4s, After-glow ≤ 4s | Qualitative (Pass/Fail) |

USA | NFPA 701 | Drapes, fabrics, films | After-flame < 2s, No drip | Pass/Fail |

UK | BS 5867-2 B/C | Curtains, mesh | Self-extinguish < 2s | Type A, B, C |

EU | EN 13501-1 | All building materials | Class B-s1, d0 or higher | A1 to F, s/d ratings |

Germany | DIN 4102-1 | Building materials and components | B1: residual length ≥ 150 mm | A1, A2, B1, B2, B3 |

Why Fire Classification Matters for Scaffold Nets

Fire-resistant scaffold nets are not just a passive safety measure—they play an active role in protecting job sites from one of the most dangerous hazards: fire. Their significance increases on complex, multi-level scaffolding systems where even a small ignition can have rapid and devastating effects.

- High-rise scaffolding: On tall structures, any fire that starts on the upper levels poses a serious risk of vertical flame spread. Scaffold nets with poor fire performance can accelerate this danger, while flame-retardant ones can slow down or halt propagation, giving workers more time to respond.

- Hot work zones: Scaffold nets are often installed near welding, grinding, and gas-cutting operations where sparks and molten materials are common. In these high-temperature zones, using non-flame-retardant nets could result in immediate ignition, making certified fire-resistant nets essential for containing potential flare-ups.

- Public or urban construction sites: When construction occurs near pedestrian areas, roads, or populated buildings, the risk to public safety escalates. Scaffold nets that meet advanced fire-retardant standards help prevent embers or burning materials from escaping and protect not just workers but also bystanders and adjacent structures.

- Emergency response compliance: Fire-rated scaffold nets ensure compliance with regional fire codes and help avoid penalties or delays caused by inspection failures. In the event of an on-site fire, properly classified nets also reduce liability and support faster insurance claims.

Ultimately, investing in certified fire-retardant scaffold nets is a proactive step in risk mitigation. It demonstrates a commitment to safety, regulatory adherence, and operational continuity—essential for modern construction projects.

How to Screen Suppliers for Genuine Fireproof Scaffold Nets

From a buyer’s perspective, ensuring that scaffold nets meet genuine fire-retardant standards requires more than just reviewing spec sheets. Here’s how to assess suppliers effectively:

Request Accredited Test Reports

Ask for recent third-party lab test reports (e.g., from SGS, TÜV, or BV) based on relevant standards like NFPA 701, EN 13501-1, or DIN 4102. Make sure the test items match the actual product type and specifications.

Verify Certification Validity

Confirm that certificates are not expired and verify their authenticity with the issuing laboratory. Cross-check the lab’s accreditation and the report number if needed.

Ask About Material Composition

True flame-retardant scaffold nets typically contain added flame retardant chemicals (e.g., brominated or phosphorus compounds). Reputable suppliers can specify the material blend and whether it’s treated or inherently flame-resistant.

Check Product Labeling and Batch Traceability

Quality suppliers label each batch with traceable IDs and production details. This allows you to track specific lots to corresponding test reports and production dates.

Inspect Sample Performance

Request product samples and, if possible, conduct small-scale flame tests to confirm self-extinguishing behavior. While this is not a substitute for certified testing, it can expose substandard products.

Evaluate Supplier Reputation

Look for suppliers with proven experience in exporting to regulated markets. Check references, client reviews, and whether they’ve previously passed EU/US compliance audits.

By applying these due diligence steps, buyers can reduce the risk of purchasing non-compliant or falsely labeled fireproof scaffold nets, ensuring safety, compliance, and peace of mind on-site.

Conclusion

Selecting the right scaffold nets for your construction site goes beyond tensile strength or durability. Fire performance has become a top-tier requirement in today’s regulatory landscape, especially across international projects where local standards differ significantly. From China’s GB 5725 to the EU’s EN 13501-1 and Germany’s DIN 4102 B1 rating, knowing what each standard demands is crucial.

For exporters and contractors alike, ensuring that scaffold nets comply with region-specific flame retardancy requirements means fewer regulatory headaches, improved worker safety, and enhanced public protection. Whether you’re managing a domestic build or a cross-border infrastructure project, prioritizing certified fire-resistant scaffold nets reflects a modern, responsible approach to construction safety. Don’t wait for an inspection failure or an accident. Audit your current stock today.

Frequently Asked Questions (FAQ)

Q1: What is the most stringent fire safety standard for scaffold nets?

A1: EN 13501-1 (EU) is the most comprehensive and widely accepted, especially B-s1, d0 class.

Q2: Are Chinese scaffold nets accepted in the EU or U.S.?

A2: Only if they are tested and certified under local standards like NFPA 701 or EN 13501-1.

Q3: What does B1 mean in DIN 4102?

A3: B1 stands for “flame-retardant material” and requires strict flame resistance and burn length limits.

Q4: How do I ensure my scaffold nets are compliant for export?

A4: Ask for test reports from accredited labs showing compliance with the target country’s standard (e.g., SGS, TÜV).

Q5: Are there universal standards for fire resistance in nets?

A5: No single universal standard exists; compliance must match local regulations.