Cuplock Scaffolding is a type of modular scaffolding system used in the construction industry for providing access and support to workers and materials at elevated heights. It consists of vertical standards (uprights) and horizontal ledgers, connected by a unique locking mechanism known as the “cuplock”. The cuplock mechanism allows the ledgers to be easily and securely locked into the uprights without the need for nuts, bolts, or wedges. This makes the system fast and easy to assemble, disassemble, and adjust on-site. Cuplock scaffolding is versatile, durable, and can be used for various applications, from small-scale residential projects to large-scale industrial constructions.

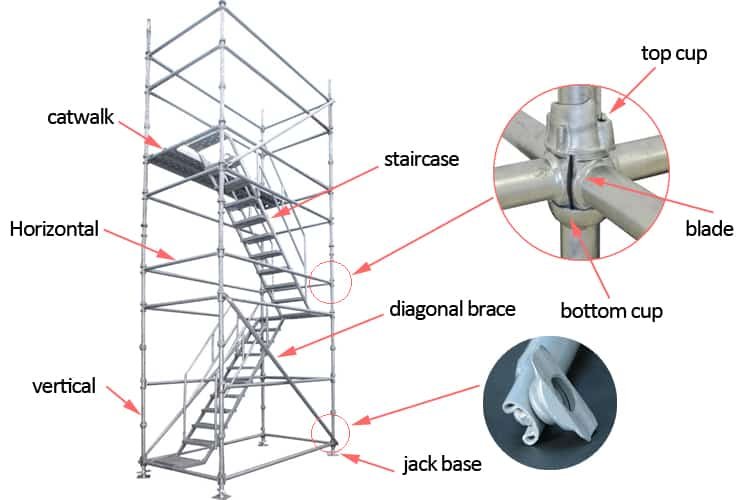

Cuplock Scaffolding is composed of several components that work together to create a safe and secure modular scaffold system. Here are some of the key components:

Verticals: Also known as standards or uprights, standards are the vertical tubes that form the structural backbone of the scaffold. They are typically made of steel and are available in different lengths and sizes to accommodate various scaffolding heights and load requirements.

Horizontal: Horizontal members that connect two adjacent standards, provide support for the scaffold platform and transfer weight to the standards. They are also made of steel and come in different lengths and sizes.

Diagonal braces: Diagonal braces connect the standards at an angle to provide lateral stability to the scaffold. They are typically used in pairs, with one brace running from the bottom of each standard to the top of the adjacent standard.

Transoms: Transoms are horizontal members that connect the ledgers to each other and help distribute weight evenly across the scaffold.

Base jacks: Used to level the scaffold on uneven ground, base jacks are adjustable steel tubes that attach to the standards at the scaffold base.

Top cups: Top cups are circular metal fittings that are located at the top of each standard. They have a cup-shaped design that allows the ledgers to be locked into place without the need for nuts, bolts, or wedges.

Bottom cups: Bottom cups are similar to top cups but are located at the bottom of each standard and are used to hold the base jacks in place.

These are some of the main components of Cuplock Scaffolding, there may be additional components depending on the specific application and configuration of the scaffold.

As a factory direct cuplock scaffolding supplier, we specialize in providing high-quality scaffolding products at competitive prices. By eliminating the middleman and dealing directly with our customers, we are able to offer significant cost savings without compromising on quality or safety. Our team of experienced professionals oversees every aspect of the production process, from sourcing raw materials to manufacturing and quality control, ensuring that each product meets strict standards for durability, strength, and performance. We also offer flexible delivery options and responsive customer service to ensure that our customers receive their orders on time and with minimal hassle. Whether you are a small contractor or a large construction company, we are committed to providing reliable scaffolding solutions that meet your specific needs and budget.

APAC has a professional technical service team, we can design and calculate the amount of scaffolding according to your needs. Don’t worry, it’s free!

We can be contacted directly via email or phone. Many of APAC’s sales have engineering backgrounds and are fluent in English and can address your questions more quickly and directly.

APAC provides comprehensive installation instructions for our products and we have filmed videos on how to install and dismantle them. You can easily set up or take down scaffolding according to our manual instructions.

Protecting the safety of your construction workers and guarding your property is our #1 priority.