lifelines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- List Item #1

- List Item #1

- List Item #1

Types of Lifelines

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- List Item #3

- List Item #3

- List Item #3

send your inquiry

lifelines | The Ultimate FAQ Guide

A fall protection lifeline or safety lifeline is an essential part of a fall restraint or fall arrest system.

Since it connects safety harnesses and lanyards, you should choose high-quality safety lifelines for your workers.

However, since the market is full of suppliers selling various safety lifelines, you may find it tricky to choose the right ones.

Do not worry; this comprehensive FAQ guide will give you ample knowledge on safety lifelines so you can shop lifelines fulfilling your requirements.

So let us begin the guide without any further delay.

Q1 What are Safety Lifelines?

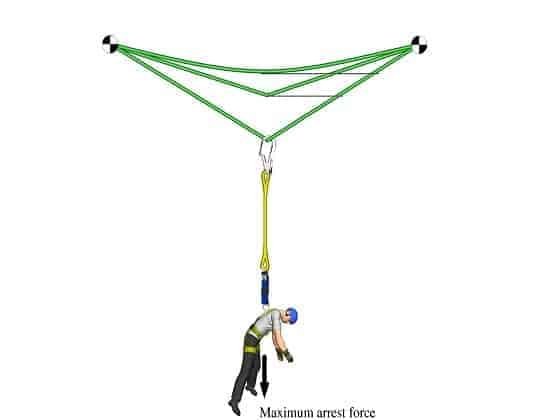

Figure 1: Safety Lifeline

Figure 1: Safety Lifeline

A safety lifeline is a fall prevention device featuring a robust cable/wire connected to anchor points, allowing the fastening of the harness and lanyard.

Safety lifelines are suitable for personnel working at elevations and who require flexibility in movement.

These lifelines are suitable at workplaces where guardrails and other fixed safety solutions are not possible.

You can say safety lifelines are part of active fall protection that connects different mechanisms of a fall arrest system.

In a nutshell, it links several components of a fall prevention system for improved protection.

Q2 What are the Types of Safety Lifelines?

Safety lifelines are available in various types.

A few common ones are as per below.

a) Horizontal Safety Lifeline

Figure 2: Horizontal Lifeline

Figure 2: Horizontal Lifeline

A horizontal lifeline is a protective wire in a safety harness that attaches horizontally to multiple anchors.

And those anchors are further attached to a fall prevention system.

b) Vertical Safety Lifeline

Figure 3 Vertical Lifeline

Vertical lifelines are ropes or cables that offer safe and comfortable fall protection to workers performing climbing duties in an upright position.

Workers stay attached to these lifelines through a full-body harness and lanyard.

c) Temporary Lifeline

Figure 4:Temporary Lifeline

Temporary lifelines are portable safety lifelines that offer quick fall protection solutions.

Such lifelines are suitable for bridges, construction sites, and rack installation.

d) Permanent Lifeline

Figure 5: Safety Lifeline

A permanent safety lifeline provides uninterrupted fall protection in a roof area.

It offers protection against fall risks with a simple anchorage system.

e) Self-Retracting Lifelines

Figure 6 Self Retracting Lifeline

A self-retracting lifeline is another popular fall prevention tool that halts a fall immediately.

The wearer attaches it to the D-ring of their safety harness.

You find this lifeline over the head of the wearer.

Self-retracting lifeline comes with a mechanical lock and prevents the user from falling beyond a couple of inches.

Q3 How Important is Safety Lifeline at a Construction Site?

A safety lifeline is a safety device made out of stanchions and wire to stop accidental falls.

A construction company must use it at places that have more fall risks.

Moreover, they must provide training to their workers for the proper use of safety lifelines.

Safety lifelines are available in several types, including horizontal, vertical, permanent, and temporal.

For vertical operations, you use vertical safety lifelines, while for horizontal works, horizontal lifelines are suitable.

Temporal safety lifelines are easy to remove.

You can remove them after every use.

On the other hand, you fix permanent safety lifelines to the permanent structures.

Safety lifelines are crucial on construction sites, building roofs, and other structures where you can not use guardrails or other safety controls.

Q4 What is OSHA Compliant Safety Lifeline?

OSHA-compliant safety lifeline complies with the guidelines of the organization named Occupational Safety and Health Administration.

The OSHA provides the following instructions for a safety lifeline.

Safety lifelines should be over the site of operation to an anchoring capable of supporting a weight of 5,400 pounds.

If you have to use lifelines in an area or surface that might split them, use at least 7/8-inch manila ropes.

For other areas, it should be ¾ inch in width.

Moreover, the breaking strength should be 5,000 pounds.

Q5 How to Store Safety Lifeline?

Generally, safety lifelines do not require that much maintenance.

However, you should clean and lubricate the safety lifeline once in a while.

It is advisable to store safety lifelines in a dry and hygienic environment, away from direct sunlight.

Before use, inspect safety lifelines precisely every time.

Q6 What is the Price of a Safety Lifeline?

It is not possible to mention a single set price for a safety lifeline.

The price of safety lifelines depends on various factors such as the origin of lifeline, material quality, type of lifeline, and the number of safety lifelines you buy.

Lots of safety lifeline suppliers give discounts on bulk orders.

If you want to know the price of lifelines, you can request various suppliers to send you price quotes based on your requirement.

Q7 How to Clean Safety Lifeline?

Cleaning the safety lifeline is straightforward.

You can use soapy water to wash the safety lifeline.

Rinse the lifeline thoroughly with fresh tap water.

If there are obstinate stains, you can use a small brush to eliminate them.

Q8 How to Inspect Safety Lifeline for Faults?

Figure: 7 Safety Lifeline Inspection

For construction companies, it is crucial to ensure that their workers are using safe and fully-working safety lifelines.

The following steps will help you inspect lifelines precisely.

Check if your safety lifeline has all the legible labels provided at the time of shipment from the supplier.

Find out if the connection point is working accurately in safety lines.

It should also turn around accurately as per the manufacturer’s recommendation.

Also, inspect all the bolts, screws, and fasteners of the safety lifelines.

Stretch the lifeline and then let it return into its housing unit to check the retraction functionality.

Test braking functionality of safety lifelines by pulling them.

Make sure at least two different actions are required to unlock the hook gate.

Q9 How to Choose a Reputable Safety Lifelines Manufacturer/Supplier?

It might be difficult to locate an ideal manufacturer if you are purchasing safety lifelines for the first time.

Nevertheless, the following tips will help you with it.

a) Market Reputation

It is not difficult to get to know the market reputation of a particular manufacturer in modern times.

Nowadays, every safety lifeline manufacturer has a website and does online promotions.

You can check out their websites to know the experience of their previous clients.

Also, check out reviews on the 3rd party websites.

Ensure their website explains each of their products comprehensively.

b) Check Product Quality

To have an idea about the quality of safety lifelines, you can visit the websites of your potential suppliers.

Most suppliers provide 360-degree pictures of their products and an in-depth product description describing all the crucial information.

c) Quality Compliances

Buy safety lifelines that comply with OSHA and ANSI guidelines.

Such lifelines ensure the maximum safety of your workers.

d) Pricing

Do not go with a random manufacturer.

Get price quotes from multiple manufacturers.

Compare product quality and pricing, and based on the comparison, make the final decision.

Q10 How to Use Horizontal Safety Lifelines?

You can use horizontal safety lifelines with various types of fall arrest or fall restraint systems.

These are primary fall prevention systems for areas that do not have existing anchor points.

A horizontal lifeline comprises a cable connected to anchor points or a stationed object.

When used along with personal protective equipment, it minimizes the risk of a sudden fall.

Q11 What are the Quality Standards for Safety Lifelines?

A quality standard ensures that the safety lifelines are meeting quality

a) ANSI

ANSI is a non-profit organization in the United States that develops safety standards for services, products, and human resources.

They keep updating their safety standards and requirements from time to time.

ANSI has a new standard, ANSI Z359.15 for the fall prevention industry.

They have established requirements for testing, inspection, storage, usage, and design criteria of safety lifelines.

b) OSHA

OSHA standard number 1926.104 mentions requirements for safety lifelines.

The standard recommends that a safety lifeline must be capable of withholding 5,400 pounds.

Moreover, the thickness of the safety lifeline should be between 4mm to 16mm.

Q12 What is the Length/Size of a Safety Lifeline?

The length of safety lifelines varies from kit to kit.

Depending on your requirement, you can buy a 160 feet, 490 feet, or 650 feet long safety lifeline.

No matter what kind of safety lifeline you buy, it should be capable of bearing the harsh environment of your workplace.

It is advisable to choose OSHA-compliant safety lifelines.

Q13 What is the Load Capacity of a Safety Lifeline?

Figure 8: Safety Lifeline Load Capacity

Figure 8: Safety Lifeline Load Capacity

Safety lifelines come with various variants.

Even different manufacturers use different materials to make safety lifelines.

Therefore, the load capacity might vary based on the type of safety lifeline you buy.

However, you can expect a good quality polyester-made safety lifeline to hold approx 5000 pounds.

Even OSHA requires a lifeline to hold 2300 kg of force.

Q14 How Do I Attach a Safety Lifeline to a Fall Arrest System?

Securing a safety lifeline is a straightforward process.

You can accomplish this using the following steps.

●To begin, tug on the free end of the rope.

●Next, secure your safety lifeline with a mule and fisherman knot.

●Now you can attach yourself to a safety lifeline with a fall protection solution.

Q15 What Is the Distinction Between Self-Retracting Lifelines and Safety Lanyards?

As a construction company, you need to ensure that all your employees are safe at the workplace.

Additionally, you should make sure that your workers are using appropriate fall prevention equipment.

People often get confused between self-retracting lifelines and safety lanyards.

Let us get to know the functions and differences of both fall prevention devices.

a) Self Retracting Lifelines

SRLs, made out of webbings or wire ropes are fall protection devices retracting automatically into their units.

Therefore, there is no slack in the lifelines.

Safety lifelines have a longer length and provide a wider working radius.

b) Fall Prevention Lanyards

Lanyards are ropes and webbings that come with a set length.

They have shock-absorbing features, making them suitable for multi-purposes.

These include work positioning, fall arrest, restraint, and more.

Since you attach them to a fixed anchor point, they limit users’ working radius.

Which fall prevention device is suitable for your workers?

It is critical to recognize that varied conditions require different fall prevention devices.

a) Job Type

If you are looking for a retrieval system, a self-retracting lifeline will be a good choice.

b) Work Range

Consider the area of your workplace as well.

Remember, with a fall prevention lanyard you will work in a six-foot radius only.

However, using self-retracting safety lifelines, you can cover a wider area.

c) Fall Clearance

It is the shortest vertical distance between the feet of workers as well as a lower level.

If you workers are working in a place where fall clearance is stable, go for a lanyard.

However, if it changes throughout the day, a safety lifeline is a good option.

d) Edge Work

Self-retracting safety lifelines are attached to an anchor point in the above place.

However, this is not an option when you have to work on the edge of a floor.

It will force workers to use the self-retracting safety lifelines horizontally that might damage the rope.

In such a working scenario, a lanyard should be your choice.

Now you know the difference between the two.

So choose them accordingly.

Q16 Where Should I Purchase a Safety Lifeline?

Nowadays, you can buy safety lifelines either offline or online.

If you want safety lifelines in bulk for your workers and looking for a supplier who can offer you the best price, go for an online method.

The online method gives you the liberty to explore safety lifelines available in the international market.

If you are looking for budget-friendly yet premium quality safety lifelines, you may consider a Chinese supplier.

In comparison to European lifelines, Chinese safety lifelines are low-cost without compromising on quality.

Chinese manufacturers provide products at affordable prices due to the affordability of raw materials, labor costs, and the shipping industry in the country.

At APAC, we provide European standard safety lifelines at a low-cost price.

We have been supplying a wide range of construction site safety solutions worldwide for several years.

You may consider buying lifelines and request a price quote for free of cost.

Our salesperson will be glad to assist you.