Introduction

During construction, PE tarpaulin and PVC tarpaulin are frequently used. For example, PE tarpaulin can be used with scaffolding to ensure that workers are not affected by wind and rain or can be made into a fence cover to slow down temporary fence corrosion, and in some other cold and snowy countries will also use temporary roofs or snow tarps, which is all made of PVC tarpaulin, to reduce the impact of heavy snow on construction.

The two materials are common in industry, so what is the difference between them? How can I choose the most suitable material for my project? I believe this blog will give you the answer.

Part 1: What is PE/PVC Tarpaulin?

PE Tarpaulin

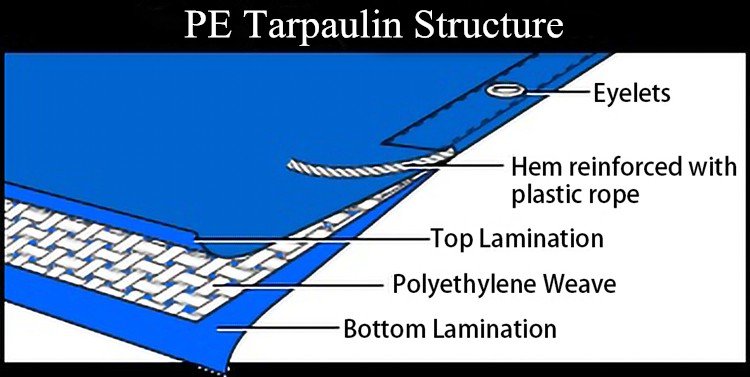

PE tarpaulin is a double-coated PE film with a loosely woven polyethylene plastic strip in the middle, and its production process is: drawing round-weaving-double side film.

Polyethylene (PE) is a semi-crystalline thermoplastic material that is divided into high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE).

Among them, HDPE is the raw material for making PE tarpaulin, it appears as white powder, or granular product, is non-toxic, and tasteless, and its density ranges from 930 to 970 kg/m3.

Advantages

PE tarpaulin has good heat and cold resistance, good chemical stability, is insoluble in any organic solvent at room temperature, is resistant to most acids and bases, has small water absorption, yet maintains flexibility at low temperatures, and high electrical insulation. And PE tarpaulin is light, clean, non-polluting, and easy to transport and store.

Lightweight and flexible: Easy to transport and install.

Affordable: A cost-effective option for temporary projects or short-term covering.

Waterproof: Protects equipment, goods, and surfaces from weather damage.

Breathable: Allows air circulation to prevent moisture build-up underneath the tarp.

- UV-resistant: Provides protection against sun damage and fading.

Disadvantages

The disadvantage of pe tarpaulin is that it is easy to wear. Thermal oxidation will make its performance decline, making it easy to age and brittle. The surface hardness of PE tarpaulin is relatively low, making it easy to scratch and stress crack. And is not suitable for long-term use in the open environment.

Applications

PE tarpaulin has many applications, such as protecting unfinished buildings from wind, rain or sunlight (reinforced polyethylene sheeting); as a temporary cover for construction materials; covering temporary fences to protect them from the weather and extend their service life; or it can also be made into tents, cargo covers, garden bag, etc.

PVC Tarpaulin

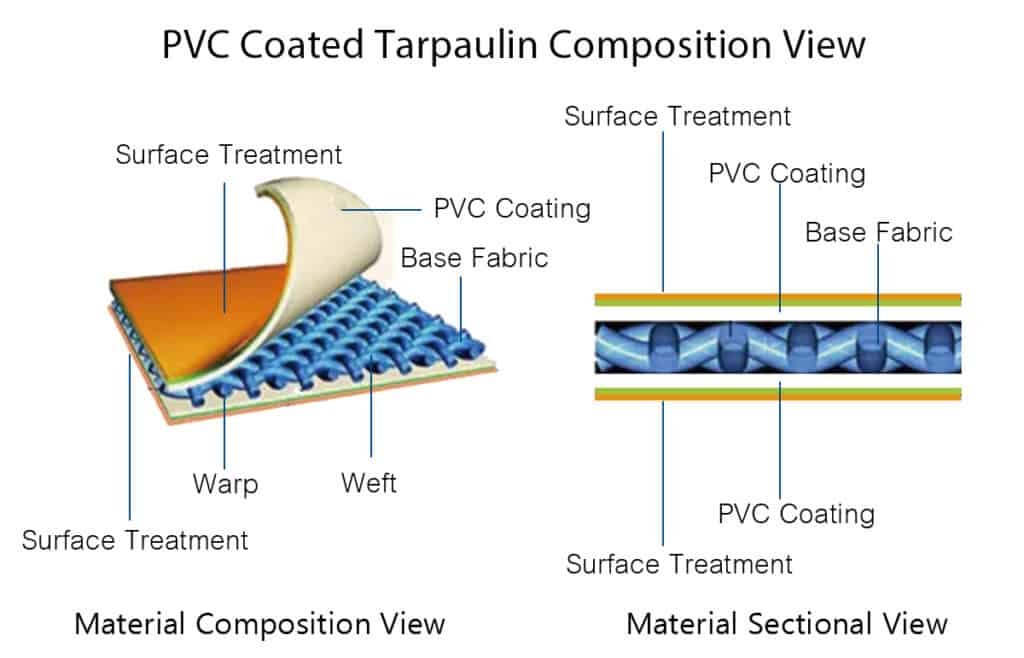

The PVC tarpaulin is made of high-strength polyester canvas, coated with polyvinyl chloride (PVC) paste resin with growth agents, anti-mildew agents, anti-aging agents, anti-static agents and other chemical additives, taking the impregnation technology, the process is: long dip coating drying set – light pressure cooling rolled.

And the raw material Polyvinyl chloride is slightly yellow translucent, glossy, and more transparent than polyethylene.

Advantages

Polyvinyl Chloride – is a tough, cost-effective material that is hard, mechanically strong and has good chemical resistance. Moreover, PVC is a natural flame retardant and has the advantages of being flame retardant (flame retardant value of 40 or more) and good electrical insulation.

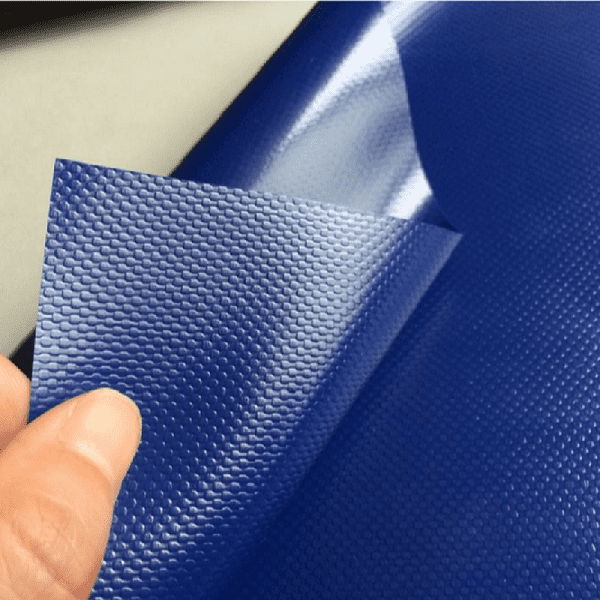

The pvc tarpaulin is characterized by high durability and sturdiness, water resistance, mildew resistance, cold resistance, aging resistance, anti-static, and can provide provide a high level of weather protection.

The pvc tarpaulin has a bright colorful appearance and a special treatment on the surface with anti-slip function, which is a popular international tarpaulin.

High strength and durability: Ideal for heavy-duty industrial applications.

Weather-resistant: Handles extreme temperatures, rain, and snow.

Chemical-resistant: Suitable for environments with exposure to harsh chemicals.

Fire-resistant: PVC tarpaulins with fire-retardant coating provide additional fire protection.

Abrasion and wear resistance: Perfect for use in high-traffic areas and rough environments.

Disadvantages

The transmittance of polyvinyl chloride tarpaulin is not very good, reducing the natural light inside the building. And When using pvc tarpaulin, it is best to avoid sharp objects scratching the tarpaulin, which will reduce the waterproof performance of the tarpaulin.

Applications

PVC tarpaulin can be used for many applications. Such as the following:

- Commonly used to cover boats.

- To make a wide variety of tents.

- Snow Tarps

- Keder roof sheeting

Part 2: How can I distinguish them?

1、Touch Method

PE tarpaulin: you can feel the woven structure (for most situations)

PVC tarpaulin: feel the lubrication with your hands, relatively smooth, and the surface is like a layer of wax coated.

2、Pull by Hand

PE tarpaulin: softer but less tough, stretching can be broken.

PVC tarpaulin: strong toughness, can be stretched wide and long, and is difficult to break easily.

3、Shaking Method

PE tarpaulin: shake with your hands to sound brittle.

PVC tarpaulin: shake with your hands and sound low.

4、Burning Method

PE tarpaulin is ignited when it meets fire; the flame is yellow, burning with paraffin-like oil drops. And have the smell of burning candles.

PVC tarpaulin because of the chlorine element; the flame is yellowish green after ignition, no oil dripping phenomenon, will be extinguished after leaving the fire source, and there is a strong pungent odor.

PVC Fabric Fire Retardant Test

5. Water Immersion Method

Immerse the two tarpaulins in water and press them into the water with your hand. To float to the top is the PE tarpaulin, and to sink to the bottom of the water is the PVC tarpaulin.

Part 3 : How can i choose them?

1. The cost and budget

Cost is often a deciding factor in tarpaulin selection. Both PE and PVC offer unique advantages, but each comes with a different price point.

PE Tarpaulins:

More affordable upfront due to the lower material cost and simpler manufacturing process. PE tarps are cost-effective for budget-sensitive projects where temporary covering is required.

Best for one-time or short-term use, where the low initial cost outweighs the need for durability.

PVC Tarpaulins:

Higher upfront cost due to the stronger material and more rigorous manufacturing process. However, PVC tarps often outlast PE tarps and offer better performance over time, making them more cost-effective in the long run.

Best for projects that require long-term durability, where the investment in PVC pays off in terms of extended lifespan and resistance to wear and tear.

Tip: If you’re working on a temporary, one-off project, PE tarps will provide the most cost-effective solution. For long-term use, especially in high-demand environments, investing in PVC tarps will save you money over time due to their durability and extended lifespan.

2. Service life

PVC tarpaulins are durable and designed to last up to 10 years. Whereas PE tarpaulin lasts about 1-2 years for a single use.

If you hold both materials, you will find that PVC tarps are thicker and more robust. This is because PVC tarpaulins have a strong internal mesh fabric and are therefore more robust.

So, if you want a tarp that will last longer or can be reused, then choose a PVC tarp, if you only use it occasionally, a PE tarp is better. Of course, combined with your budget, order quantity, price, and other factors to consider before making a choice.

3. Application Scenarios

Compared to PE tarpaulins, PVC tarpaulins offer higher durability and sturdiness, providing a high level of weather protection, winter protection, and especially resistance to environmental influences, while PE tarpaulins tend to become brittle in low temperature conditions. So if you need to use it in low temperature conditions, of course, you should choose PVC tarpaulin.

But compared to PVC tarpaulins, PE tarpaulins have better light transmission, so if you want it not to be too dark, pe tarpaulins are better.

In addition to the above scenarios, there are many application scenarios that will affect your choice. It may be worthwhile to contact us directly. Our experts will give you professional advice to help you choose the most suitable tarpaulin for your projects.

Conclusion

PE and PVC tarpaulins each have their place in the construction, agricultural, and industrial sectors, offering distinct advantages based on project needs and budget considerations. Whether you require a lightweight, cost-effective option like PE, or need the superior strength and durability of PVC, these materials provide the protection you need.

If you still have doubts about this after reading this blog, contact us immediately!

FAQ Guide

What material is used for tarpaulins?

Tarpaulins can be made from a variety of materials, including canvas, nylon, PP, PE, PVC, etc. Tarpaulins made from different materials have their specific usage scenarios, watch this blog <The Material Guide of Tarpaulin> to learn more about tarpaulins made from different materials and their advantages and disadvantages!

Are Tarpaulins Waterproof?

No, not all tarpaulins are waterproof, due to different materials or treatments, some tarpaulins are less waterproof, but after waterproofing they can have good waterproofing properties, or we would also recommend to buy tarpaulins made of polyethylene. However, if you have more strict requirements for the waterproof performance of the tarpaulin, we recommend you to emphasise this with the sales person, and we will recommend the most suitable style for you, the

What are the different grades of tarpaulin?

Tarpaulin grades are differentiated according to the GSM value, i.e. grams per square metre. The higher the GSM number, the stronger the tarpaulin, watch this blog <The Guidance of GSM In Tarpaulin> to see how GSM is tested.

How to Get Eyelets in Tarpaulin?

1. If you are using it for personal use and have a small amount of tarpaulin, you can go online and buy a diy kit to make your own eyelet for the tarpaulin. The advantage of this is that it is flexible and you can choose the position freely. But maybe it take some times.

2. You can also just buy this type of tarp so you don’t have to do it yourself.

Can I get a custom-sized tarpaulin?

Yes, we offer custom-made tarpaulins, you can decide your own tarpaulin material, colour, treatment, GSM, etc. Feel free to talk to our tarpaulin experts.