Ringlock Scaffolding Standard

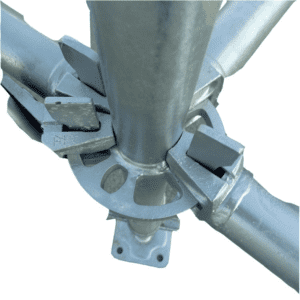

A Ringlock scaffolding standard is the vertical upright in a ringlock scaffolding system. It’s the main load-bearing member that transfers loads down to the base, and it has rosettes (ring discs) welded at regular intervals (commonly every 0.5 m) so ledgers, braces, and other components can be quickly locked in at multiple angles.

Typical features:

Vertical tube (upright) with welded rosettes for modular connections

Connects to other standards using a spigot/connector pin (depending on system design)

Works with base jack/base collar, ledgers, diagonals, and decking to form the scaffold structure

More details about RINGLOCK SCAFFOLDING STANDARD

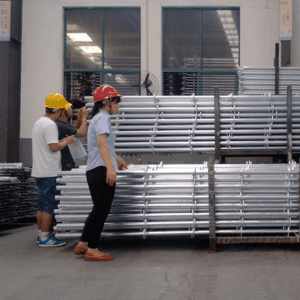

APAC is a manufacturer and supplier of various ringlock scaffolding standards and metal parts. Get in touch with us right now to receive a reasonable quote for premium Ringlock scaffolding standards. With our vast industry experience, we can meet your demands whether you need a specific solution or a dependable supplier for your ongoing projects.

A vital component of numerous industrial, event, and construction applications, Ringlock scaffold standards are versatile. Durability, adaptability, and ease of setup make safe, trustworthy, and versatile scaffolding systems popular choices for projects. Whether they are for large infrastructure projects, delicate restoration work, or temporary event constructions, Ringlock scaffold standards provide the support and stability needed to finish jobs efficiently and safely.

| Tube Material | Q355B / Q235B |

| Rosette | Q345B / Q235B Carbon Steel, 10mm thick |

| Surface treatment | Hot-dip galvanized for longevity use |

| Standard | EN12811 |

| Compatible | Modular |

The vertical parts of the Ringlock scaffolding system are called Ringlock Scaffolding Standards, sometimes referred to as uprights, posts, or scaffolding poles. These standards, which come with multiple rosette rings and scaffold tubes, are essential to the modular scaffold configuration.

Why Choose APAC Ringlock Scaffolding Standard

APAC Ringlock Scaffolding Standards are designed to provide flexible, secure, and easy-to-assemble scaffolding solutions for various construction projects. Engineered to meet the highest standards of strength, safety, and efficiency, APAC offers a proven solution for reliable vertical support and modular scaffold systems.

Modular Flexibility for Diverse Applications

APAC Ringlock scaffolding standards provide multiple connection points at various heights, enabling the system to be customized for different structural configurations. Whether you are working on high-rise buildings, industrial plants, or complex infrastructures, the Ringlock system’s flexibility allows easy adaptation to any scaffold design.

- Quick to adjust for varying project requirements

- Compatible with other scaffold types

- Ideal for both temporary and permanent installations

Hot-Dip Galvanized for Maximum Durability

APAC’s Ringlock scaffolding standards are hot-dip galvanized, providing superior protection against corrosion and wear, particularly in harsh environments or areas exposed to moisture and chemicals. This durable finish ensures that the scaffolding can withstand the elements and retain its strength over an extended period, making it ideal for long-term use in construction projects, reducing the need for frequent maintenance and replacement.

Hot-dip galvanized for superior corrosion resistance

Ideal for moist or chemical-exposed environments

Long-lasting performance in all weather conditions

Comprehensive Project Support

At APAC, we don’t just supply scaffolding; we offer comprehensive project support from design to installation. Our team of experts will work with you to ensure that your scaffolding system fits seamlessly into your project, offering guidance, customization, and ongoing support to help you meet your construction goals.

Design consultation and custom scaffolding solutions

On-site installation support for fast, error-free setup

Ongoing customer service for troubleshooting and support