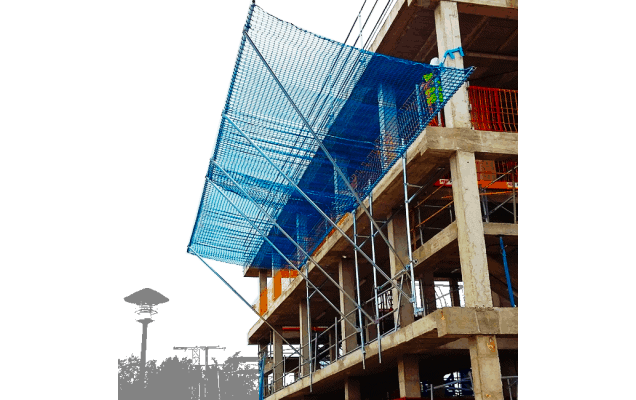

Safety Net Fans

APAC has developed APAC Safety Net Fans because of the results of a comprehensive study of the issues related to falling objects and workers and the risk of falling objects to workers or members of the public.

Unlike similar products, APAC Safety Net Fans have a special capacity to adjust to different building shapes, facades, and materials, in contrast to comparable items on the market. Additionally, it handles large wind loads well, especially in exposed and high-rise structures. The Safety Net Fan reduces the risk of injuries and possible lawsuits by safely containing falling objects and safeguarding property, the general public, and construction site workers.

APAC: Your Leading Safety Net Fans Supplier

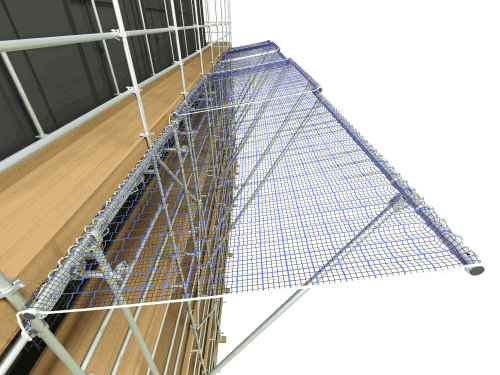

APAC’s safety net fans are pre-assembled units that can be used in any structure and adapt to any shape. The system is available in two models: standard width and extra-wide, for the safe capture of objects and debris. Different sizes are available to perfectly adapt to your requirements and application system.

APAC Safety Net Fans address these risks on-site by absorbing falling energy and containing falling objects or people within the net. Safety net fans catch and secure falling objects to protect the public, site workers, vehicles, and other property.

The flexibility and resilience of the safety net fans system mean that if the net is impacted, it will form a collection pocket around the trapped object, reducing the impact of the fall and preventing it from falling outside the safety net fans system.

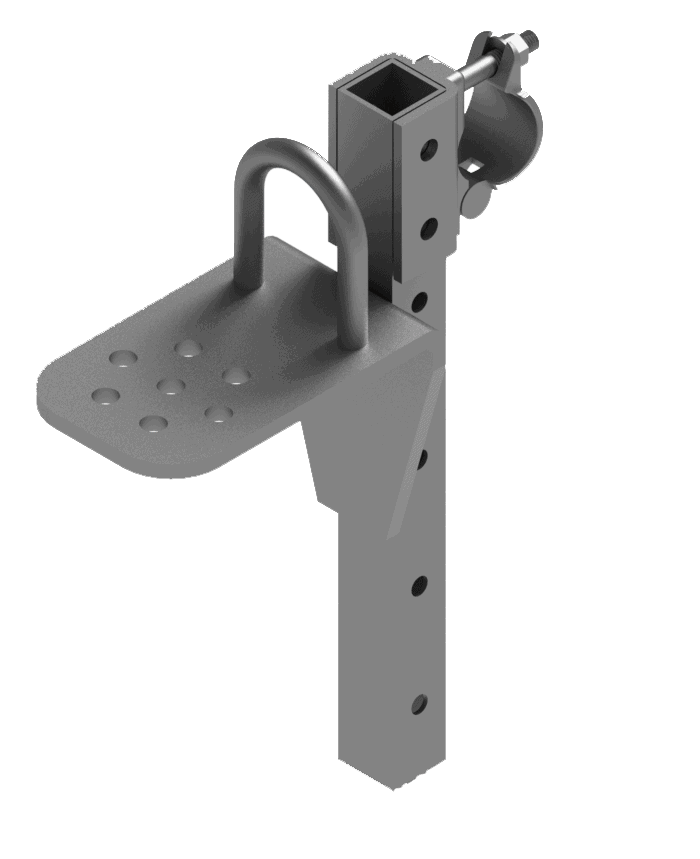

The Components of Safety Net Fans

The lightweight construction of the APAC safety net fans system ensures you to install and handle it easily, the Safety Net Fan (SNF) for APAC is the latest innovation in high-rise building protection and is ideally suited for compact downtown areas where space is limited and protecting people and property from potential hazards is critical.

The fan layout helps improve access to the site compared to traditional protection methods by allowing workers to work in areas where temporary removal of edge protection is required, provided they use restraints.

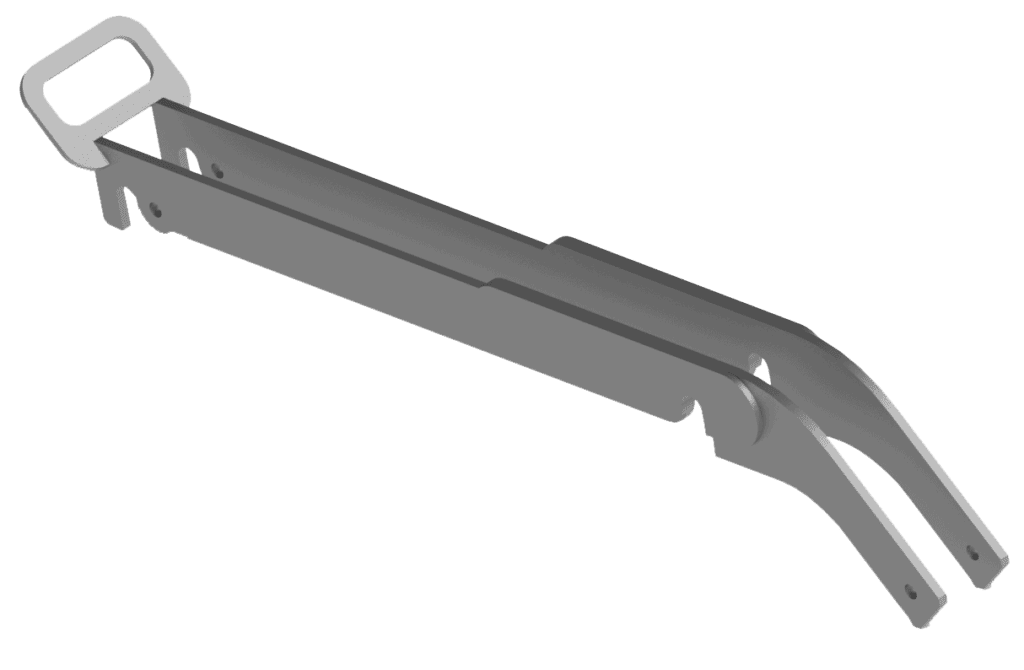

Top Bracket

The top bracket is an accessory to the safety net fan system and is used to mount the safety net fan system on the upper surface of the poured concrete slab.

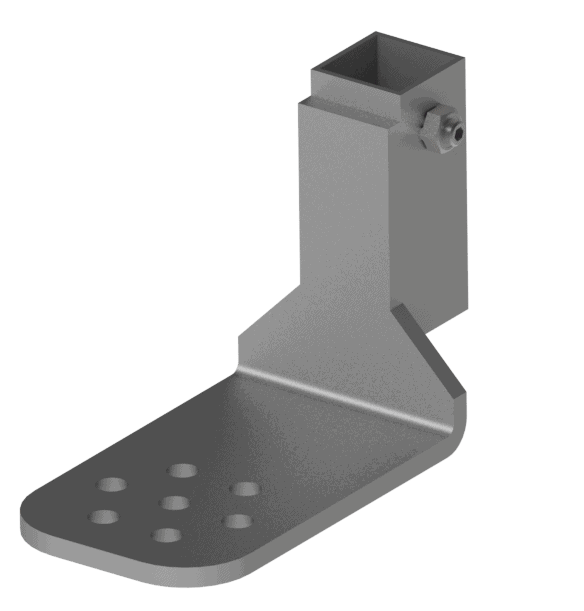

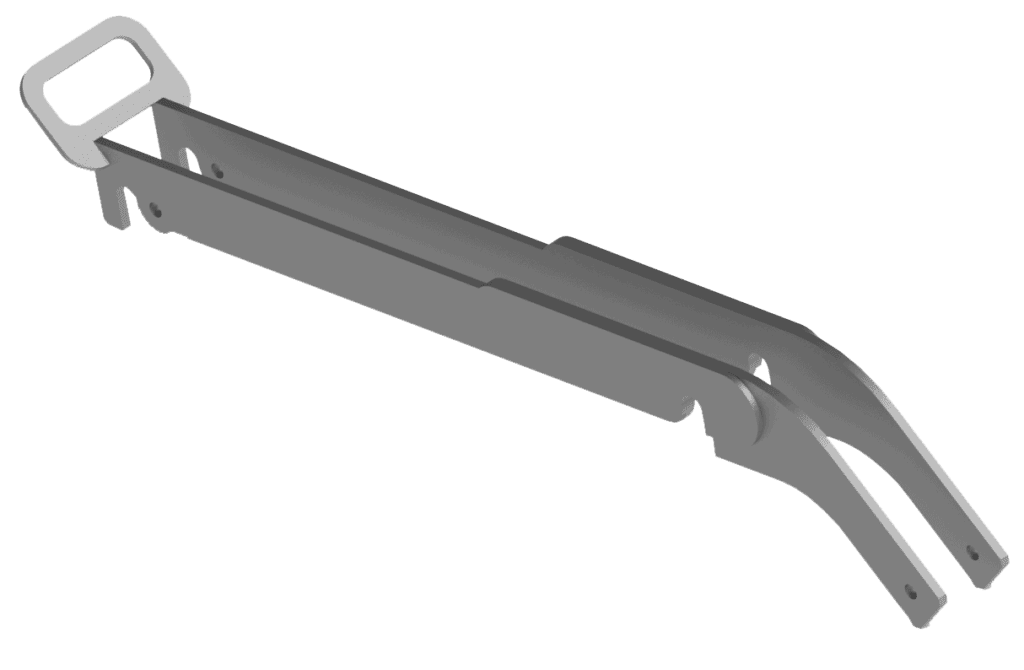

Bottom Bracket

The Bottom Bracket is the attachment of the Safety Net Fan system. It is mounted to the floor below by the screw bolts to provide support for the system.

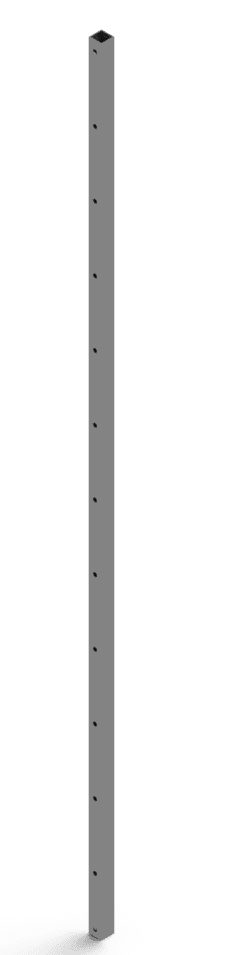

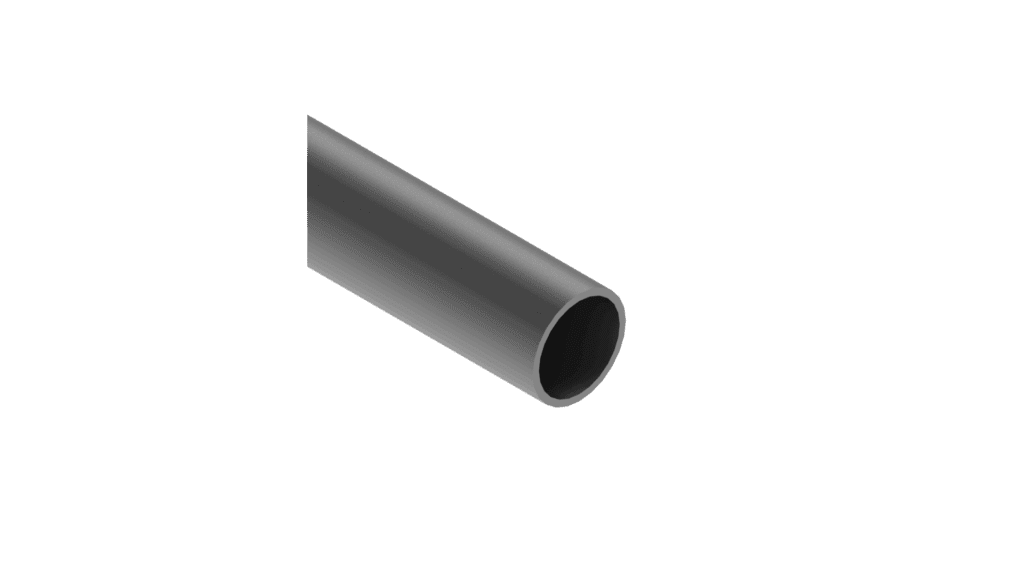

Telescopic Post

The Telescopic Upright Outer Tube will be bolted to the Top Bracket, the telescopic inner tube has 13 holes, in increments of 200mm / 8″ and should be adjusted to the correct setting before installation commences.

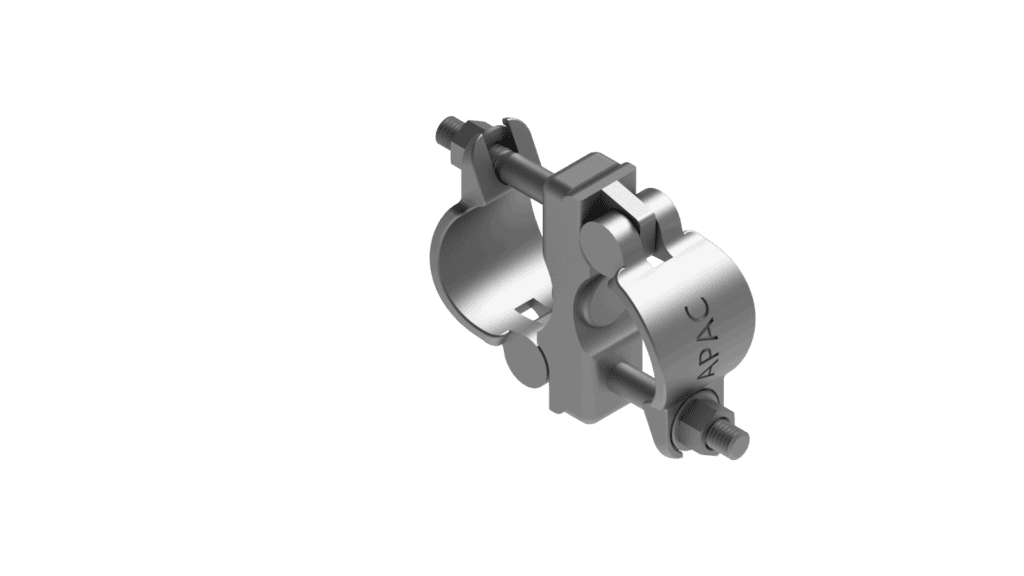

Scaffold Coupler End Clamp

The End Clamp is the right angle clamp, normally is drop forged and Hot dipped galvanized or Zinc plated surface finishing.

Retainer Brackets

APAC’s Retainer Brackets are horizontal parts of the Safety Net Fan system. They will be bolted to the support arm on one side. Another side will be locked to the Telescopic Upright with a spring pin.

Horizontal Scaffold Tube

The horizontal scaffold tube is a scaffold tube with two holes in the ends, APAC provides two types of horizontal scaffold tubes for safety net fan, 4m, and 6m.

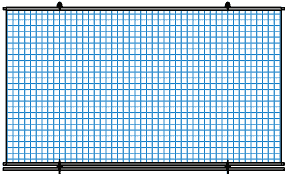

debris net

Material: Polyester yarn

Color: Green or as your request

Rope diameter : Approx. 6mm

Mesh size : Approx. 30mm x 30mm

support arm

The Support Arm is the scaffolding tube with holes inside. It is the brace member of the APAC Safety Net Fan System.

Your Best Safety Net Fans Partner in China

Manufactured in full compliance with European Standard EN-1263 Type T, APAC uses 60×60 and 20×20 layered nets capable of stopping a 100kg mass twice in any part of the safety net fans system from a drop height of 7m (approx. 2 layers).

APAC safety net fans have UV treatment to resist sun damage, except comply with EN1263-1:2004, APAC safety net fans system is also compliant with ANSI A10.37, debris net systems used during construction and demolition operations various connectors available to allow attachment to any structure.

Designed to be secured directly to buildings or scaffolding during construction, the APAC SAFETY NET FANS SYSTEM is available in a variety of sizes and accessories for easy installation. The system is made of 100% HDPE (pure high-density polyethylene), available in two or three layers, and manufactured according to standard EN 1263-1:2014.

Designed to be secured directly to buildings or scaffolding during construction, the APAC SAFETY NET FANS SYSTEM is available in a variety of sizes and accessories for easy installation. The system is made of 100% HDPE (pure high-density polyethylene), available in two or three layers, and manufactured according to standard EN 1263-1:2014.

All nets for the APAC safety net fans system come with a side line rope for added durability and are available in standard sizes of 3.1 wide and 25 meter rolls. Custom widths and lengths are also available.

Safety net fans Application:Prevents workers from falling,also prevents light materials and debris from falling

Safety Net Fan | A Complete FAQ Guide

1.What Is Safety Net Fan?

The safety net fan is a complete set of components that you can use to lessen the risk of falling hazards and ensure worker’s safety. The main feature is that you can assemble all the components into a single, complete unit before installation.

You can assemble the individual components on the ground or any area into a complete setup. Once you finish, you can use a crane system to lift and position the unit at the installation area. Due to the high adaptable features, you can quickly install them on different kinds of structures.

Figure 1 – Safety Net Fan

Figure 1 – Safety Net Fan

2.What Are The Benefits Of Safety Net Fans?

The demand for a safety net is increasing day by day due to the numerous benefits. Some of the common benefits are:

- Assembly of the unit is very easy. You can use very minimal tools to assemble the components.

- It takes a very short time to assemble the components.

- The creative design prevents the debris from falling and keeps the people safe below.

- The safety fan net comes with a complete set of components. You don’t need to buy additional components for its installation.

- You can pre-assemble the complete unit before installation. For assembly, you can choose other areas or the installation area itself.

- They are excellent to withstand high wind speeds. So, you don’t have to dismantle them in natural occurrences within limited wind velocity.

- You can quickly and easily dismantle it once you have completed your work in an area. For dismantling, you don’t have to open the individual components. Rather, you can open up as a whole unit. If you want to reuse it, you can reposition to another site or area as a whole unit.

- A single set of the unit includes two to three layers of safety net. So, it is suitable for both debris and worker’s fall protection.

- You can install it on buildings with overhanging structures.

- You can directly fit the safety fan net on steel and concrete frames of structures.

- Safety net fan is suitable to use with scaffoldings.

- The creative design of the net and the frame flexibly operate to eliminate the chance that the debris might bounce off after falling on the top of the net.

- When an amount of debris is collected on top of the frame, you can easily fold the frame to remove the collected debris

- The unit is highly portable since the components are made from lightweight materials.

3.A Safety Net Fan Should Comply With Which Standards?

The safety netting is made with high-density polyethylene (HDPE). This material conforms to the standard EN 1263-1:2014.

This standard is applicable for the material that you are using to manufacture the safety net. According to the standard, in extreme weather conditions, the material must be able to retain its properties to avoid any chance of risk.

4.What Are Basic Elements Of Safety Net Fans?

The basic components are:

- Safety net:The safety net is the principal element. It prevents the debris and workers from falling. The safety net is made from high-density polyethylene (HDPE), which is a heavy-duty material. There are also two to three layers of netting for complete protection.

Figure 2 – Safety Net

Figure 2 – Safety Net

- Top bracket:You can secure a strong connection with the floor on the top level with the top bracket. For connection, each bracket has seven holes at the base. You Use screws to secure the connection on concrete floors.

- Telescopic post:You can extend or retract a telescopic post. This is necessary if you require to customize the telescopic post with the floor height where you are installing.

- Locking brace:There are two sets of telescopic posts to hold the safety net. With the locking brace, you can lock the safety net between the telescopic posts.

Figure 3 – Locking Brace

- Right angle coupler:With the right angle coupler, you can attach the telescopic post with the scaffold tube of the debris net. The couplers have a diameter of 48 mm to fit the tube diameter.

- Swivel coupler:Swivel couplers are hot-dip galvanized. They are also used to attach the telescopic post with the scaffold tube of the debris net.

- Bottom bracket:With the bottom bracket, you can secure a strong connection with the floor on the bottom level with the bottom bracket. For connection, each bracket has seven holes. You use screws to secure the connection on concrete floors.

- Scaffold tube:The scaffold tube is used to hold and install the safety net.

5.Can You Install Safety Fans On Scaffoldings?

Yes, you can install them with scaffolding structures. They are highly adaptable. So, you can use it for various types of structures. If you want to install them on scaffoldings, use the additional attachment parts.

Figure 4 – Safety Fan Net On Scaffolding

6.How Does The Safety Net Fan Work?

The net fans are made in a creative design adaptable for modern application scopes. They are designed to efficiently catch the falling person and debris. When the falling object hits the safety nets, the net and frame system acts in an elastic nature to gradually expand towards below and create a pocket to entrap the materials.

This helps to increase the surface area to reduce the impact of the sudden fall. The net will bring the object or debris to a gradual stop. Due to these two factors, the force of impact will reduce, which will save the person. Moreover, the debris will not bounce off. When the falling debris gradually loses its falling energy, it will come to a stop within the pocket.

7.Are The Safety Net Fans UV Treated?

Yes, the safety net of the frame is UV treated. This helps to keep the safety netting protected against the harmful effects of UV rays. So, you can expect extended durability for your safety net and avoid discoloration after long usage.

More Question?

Just send us your detailed project requirement, we will give you the best solution accordingly.