What Are Scaffolding Couplers?

Scaffolding couplers are important parts used in construction to connect scaffolding tubes securely. They help create a strong framework that supports workers, tools, and materials at different heights during building and maintenance tasks. Understanding scaffolding couplers is crucial for keeping construction sites safe and efficient.

The main job of scaffolding couplers is to join scaffolding tubes together. This connection ensures that the scaffolding structure stays strong and can safely hold heavy loads without any accidents.

Scaffolding Coupler Materials & Manufacturing

1. Base Materials

Most scaffold couplers are made from steel or aluminium.

Steel couplers

Used for heavy-duty applications and general construction.

High tensile and shear strength.

Suitable for standard 48.3 mm OD steel tubes (EN 39 or similar).

Preferred for high loads, industrial scaffolds, and shoring.

Aluminium couplers

Much lighter than steel, which helps reduce manual handling strain.

Often used with aluminium scaffold tubes or mixed systems.

Suitable for many access applications but typically have lower SWLs (Safe Working Loads) than equivalent steel couplers.

Common in projects where speed and low weight are more important than maximum capacity (e.g., light access, event structures).

2. Manufacturing Methods

Two main manufacturing methods are common:

Drop-forged couplers

Produced by hot-forging steel into precise shapes.

Very high strength and excellent impact resistance.

Better dimensional accuracy and long-term durability.

Typically the premium option for demanding sites and long service life.

Pressed steel couplers

Made by pressing steel plate into shape and welding where necessary.

Usually lighter and sometimes cheaper than forged couplers.

Suitable for many standard applications, but often with lower SWLs than forged equivalents.

3. Protective Coatings

To resist corrosion and extend service life, couplers are usually:

Hot-dip galvanized

Thick zinc coating.

Excellent corrosion protection, especially in outdoor or coastal environments.

Electro-galvanized / zinc-plated

Thinner coating.

Acceptable for many environments, but not as durable as hot-dip galvanizing in aggressive conditions.

Choosing the correct material + manufacturing method + coating combination will determine:

How long couplers can remain in safe service

How much maintenance and inspection they need

Whether they can withstand harsh weather or industrial atmospheres

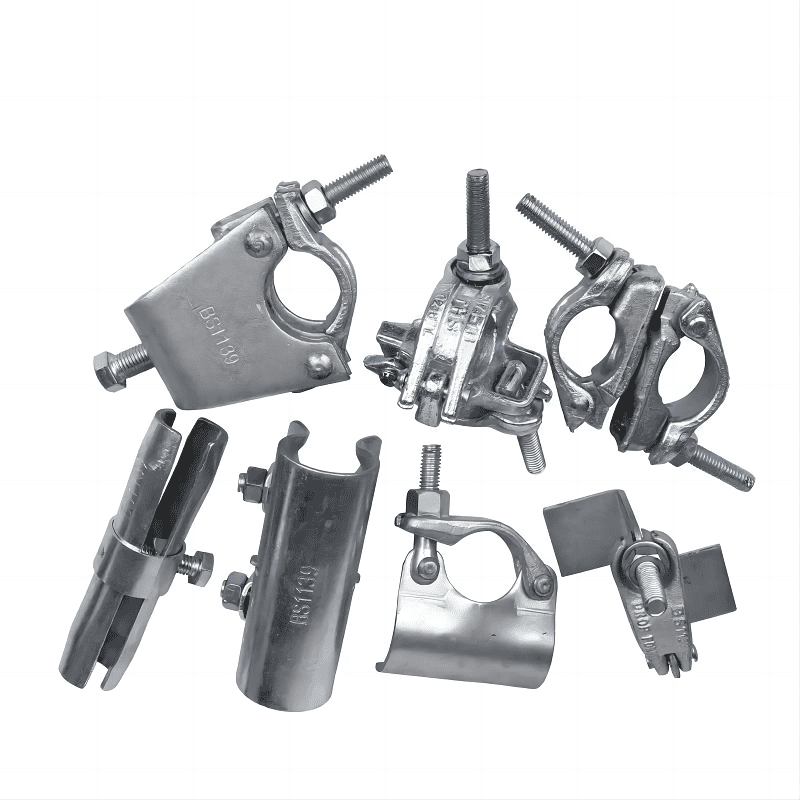

Types of Scaffolding Couplers

Scaffolding couplers are designed for specific connection types and load paths. Using the wrong type in the wrong place is one of the most common causes of unsafe scaffolding.

Below are the main coupler types and where they are typically used.

Swivel Couplers

Function:

Join two tubes at any angle from 0° to 90° (and sometimes beyond), thanks to a swiveling central pin.

Typical uses:

Fixing diagonal braces between standards and ledgers.

Connecting tubes around obstacles.

Adjusting to irregular geometry or following sloping roofs and facades.

Key characteristics:

Provide flexibility in layout and are essential for bracing.

Not usually designed to carry the same primary bending loads as right-angle couplers unless the manufacturer specifically states so.

Available in both drop-forged and pressed steel versions.

Best practice:

Use swivel couplers mainly for bracing and secondary connections, not as the main joint between standard and ledger unless allowed by the design.

Ensure the swivel pin is not excessively worn and that the coupler can rotate smoothly but lock firmly.

Right-Angle Couplers

Right-angle couplers, also called 90-degree couplers, are the most common type. They connect tubes at a right angle (90 degrees), creating strong, sturdy joints. These couplers are essential where tubes meet perpendicularly, ensuring the scaffolding remains firm and can support weight.

Sleeve Couplers

Sleeve couplers connect two scaffolding tubes end-to-end. They extend tube lengths securely, maintaining the scaffolding structure’s strength and stability. Sleeve couplers are used when longer tubes are needed without compromising safety.

Putlog Couplers

Function:

Attach a putlog or transom tube to a ledger or standard, typically supporting scaffold boards or planks.

Characteristics:

Usually have a single jaw that grips one tube.

The other end of the putlog often has a flattened “blade” that sits in a brick joint or on a support.

Usage:

Light-duty platform support in traditional bricklayers’ scaffolds.

Not generally used as a main load-bearing coupler in modern heavy-duty scaffolding.

Best practice:

Use putlog couplers only where indicated by design and within their rated SWL.

Do not substitute them for double couplers in primary joints.

Beam Couplers

Also called: Girder couplers, beam clamps.

Function:

Connect scaffold tubes directly to structural steel beams or girders, allowing the scaffold to be anchored to or supported by the base structure.

Types:

Right-angle beam couplers – tube at 90° to the beam flange.

Swivel beam couplers – tube can be fixed at various angles to the beam.

Applications:

Suspended scaffolds hung from beams.

Needle beams for cantilevered platforms.

Tying scaffold frames back to primary steelwork for stability.

Best practice:

Ensure correct orientation so the coupler bears properly on the beam flange.

Use only rated beam couplers for tension / suspension; do not improvise with standard double couplers.

Follow design instructions for the number of couplers per connection and any need for check couplers.

Board Retaining Couplers

Function:

Secure scaffold boards or steel decks so they cannot slide or lift, especially at platform edges or where boards are not fully restrained by transoms.

Applications:

At the ends of boards resting on transoms or ledgers.

Along edges of platforms to prevent boards being dislodged by wind or impact.

Where boards span between non-standard supports.

Key points:

They do not usually carry major structural loads but are essential for fall prevention and trip hazard control.

Often used together with toe boards and guardrails as part of the full edge protection system.

Joint Pin Couplers

Function:

Connect two tubes end-to-end with an internal pin inserted into both tube ends.

Types:

Internal joint pins (inside tube).

External spigot couplers (clamped around tube ends, sometimes used with pins).

Applications:

Extending standards vertically.

Some systems use joint pins as a lighter alternative to sleeve couplers in axial applications.

Best practice:

Check whether the joint pin is rated for axial only or axial + bending (sleeve couplers are generally better for bending continuity).

Ensure pins are properly secured (e.g., with spring clips or locking pins) and cannot slip out.

scaffold swivel coupler

scaffold putlog coupler

scaffold board clamp

Sleeve Coupler Clamps

Scaffolding Couplers Maintance

Regularly inspecting couplers during use is essential. If any couplers show signs of wear, rust, or damage, they should be replaced immediately to prevent issues with the scaffolding structure, which could lead to serious accidents.

At the end of a project, it’s important to promptly collect the scaffolding couplers, categorize them, and store them in a dry, cool place (preferably indoors). Keep track of their quantity and usage for future projects.

In general, if scaffolding couplers are stored properly, they can be reused multiple times. However, it’s important to prevent rust; if any couplers show signs of rust, they should be removed and treated accordingly. It’s also advisable to conduct annual anti-corrosion treatments. Additionally, small components can easily be lost, so be sure to collect them promptly.

Scaffolding couplers Applications

Scaffolding couplers are crucial in construction for connecting scaffolding tubes securely. They serve several important purposes:

Supporting Structures

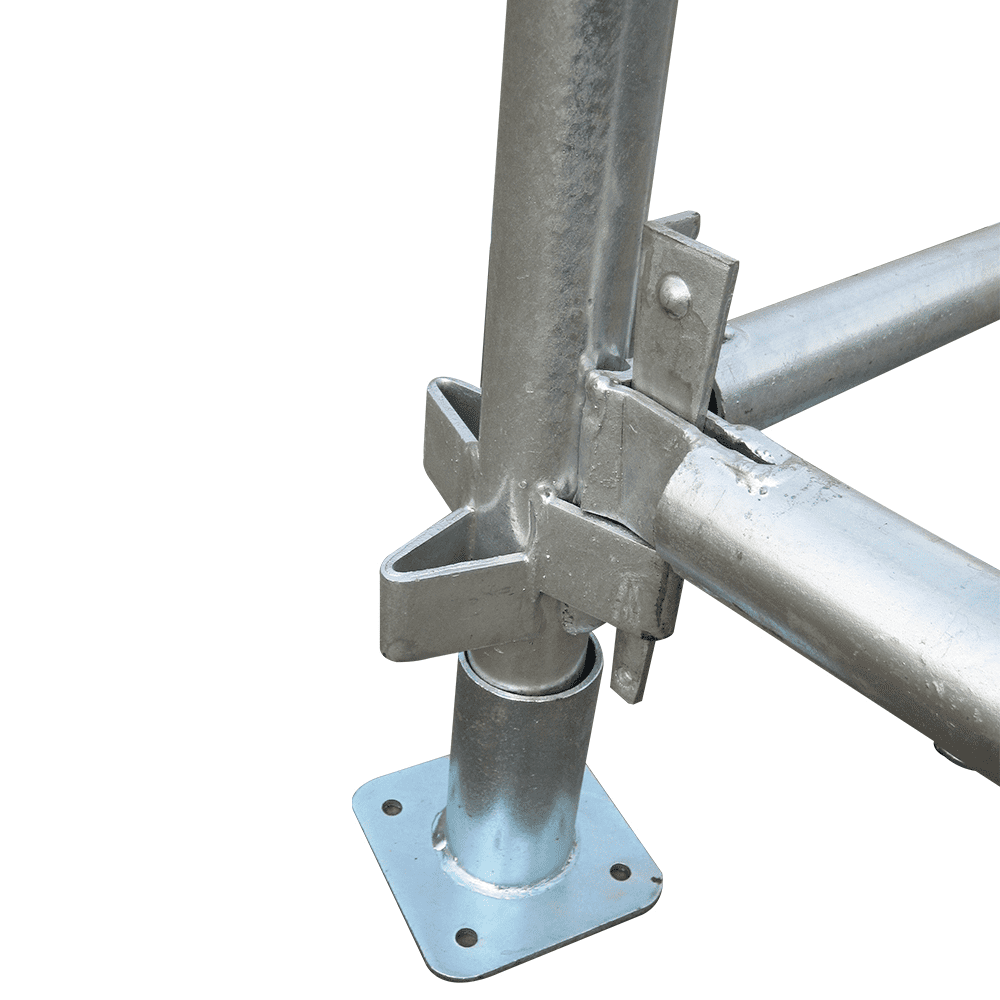

Couplers help build scaffolding frames that hold workers, tools, and materials at heights during construction, maintenance, or renovation.

Creating Platforms

They connect horizontal parts like ledgers and putlogs to vertical poles, forming stable platforms for workers to stand on safely.

Shaping Complex Structures

Couplers allow scaffolding to fit around odd shapes or obstacles by connecting tubes at different angles.

Securing Scaffold Boards

Board retaining couplers keep scaffold boards from slipping, ensuring a safe surface for workers to walk and work on.

Anchoring to Buildings

Anchor couplers hold scaffolding firmly to buildings or structures, preventing movement during windy conditions.

Connecting Beams

Beam couplers join scaffolding tubes to beams or girders, making the structure stronger and more stable.