Since its introduction, ringlock scaffolding has won wide acclaim in the market for its rich features, easy dismantling and assembly operations, and excellent high load-bearing capacity. However, in today’s market environment where scaffolding factories are numerous, it has become a challenge to purchase ringlock scaffolding of excellent quality. Quality scaffolding is crucial for ensuring construction safety, so we need to have the ability to distinguish between inferior and quality products.

Next, I will share with you some purchasing tips to help you better choose quality ringlock scaffolding.

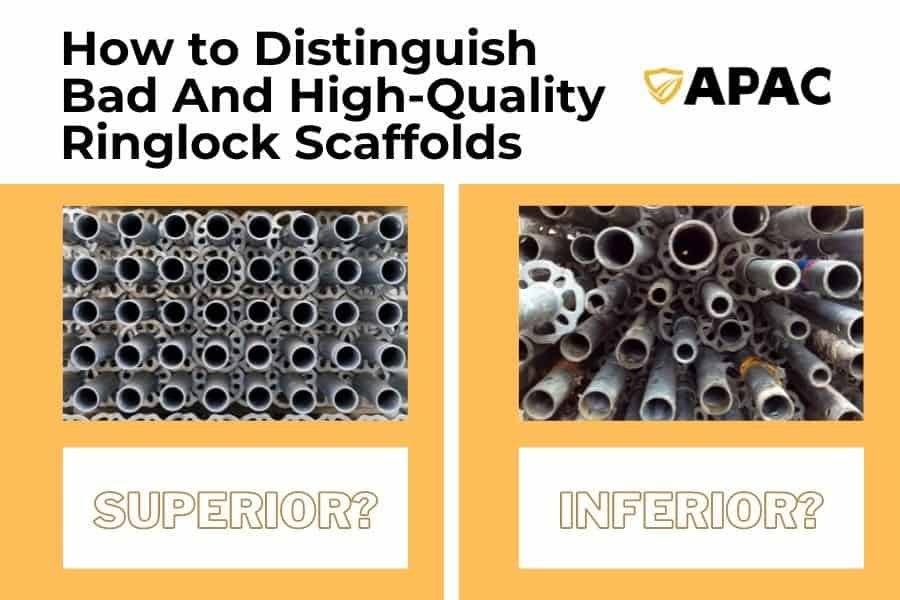

Characteristics of Poor-Quality Ringlock Scaffolding

Poor Quality of Raw Materials

The appearance of poor-quality scaffolding often appears rough, with many surface defects, such as scarring. This is because manufacturers, to reduce costs, use inferior raw materials and relatively rudimentary equipment, leading to issues like steel sticking and scarring in the products. Additionally, poor-quality scaffolding is prone to cracking, mainly due to the presence of numerous pores in the raw material, which are affected by thermal stress during the cooling process, resulting in cracks.

Poor Metallic Luster

Upon careful observation of poor-quality scaffolding, you’ll notice a lack of metallic luster, with colors possibly appearing faint red or resembling raw iron. This is mainly due to substandard material usage and improper rolling temperature control. Generally speaking, some factories have substandard management and they judge the rolling temperature directly by visual inspection, which results in the performance of steel not being able to meet the standard.

Substandard Safety Performance

Even more concerning, the safety performance of poor-quality scaffolding often fails to meet standards. It lacks sufficient strength, has poor load-bearing capacity, and is prone to issues like cracking or bending during use. Therefore, it is crucial to carefully examine the product’s strength test report when making a purchase. Poor-quality scaffolding often lacks rigorous safety testing and certification, leading to potential deficiencies in load-bearing capacity, wind resistance, and anti-slip performance, posing significant safety hazards to users. To ensure construction safety, it’s imperative to differentiate between poor-quality and high-quality ring-lock scaffolding and choose those products that have undergone rigorous quality testing.

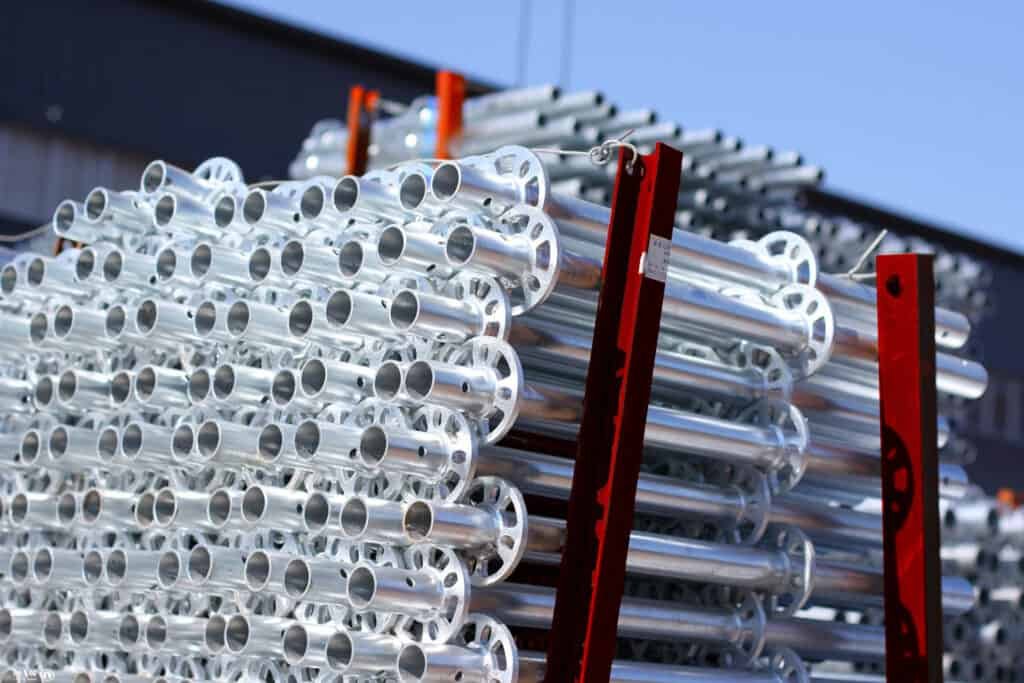

Characteristics of Quality Ringlock Scaffolding

- High-quality ringlock scaffolding is made from superior materials with uniform composition, and it undergoes cutting with high-tonnage cold shearing machines, resulting in smooth and neat end faces.

- The strength of high-quality ring-lock scaffolding is higher, making it less prone to bending, cracking, or damage.

- In addition, the products must undergo rigorous testing and be accompanied by detailed test reports and product certificates of conformity. These necessary documents can be requested from the manufacturer during the purchase process to ensure that the product purchased is fully compliant with the standards.

- In addition, to enhance the durability and corrosion resistance of the product, the surface of the product should also be hot-dipped galvanized to effectively prevent rusting.

How to Distinguish Between Good and Bad Ringlock Scaffold

Raw Material

High-quality ringlock scaffolding typically employs Q345B steel that meets international standards. The steel pipes should be straight, with a permissible deviation in straightness of 1/500 of the pipe length. Both ends should be flat, without bevels or burrs. The steel pipes should be free from cracks, indentations, or rust, and butt-welded steel pipes are not allowed.

On the other hand, inferior ringlock scaffolding may be made from recycled materials or substandard steel with insufficient strength. Some companies might reprocess recycled materials to pass them off as good quality. Scaffolding made from substandard materials fails to meet the required load-bearing capacity and is prone to collapse. After some use, these inferior steels are susceptible to bulging, cracking, and other issues, leading to safety accidents on construction sites.

This type of ringlock scaffolding often attracts consumers with low prices in the market. However, when making a purchase, we should not be solely swayed by low prices. If we only focus on price and ignore product quality, it is very likely that we will inadvertently purchase inferior scaffolding. After all, high-quality and affordable products are not common in the market. Consumers should weigh the pros and cons and make rational choices when making purchases.

Exterior Appearances

The surface of castings should be smooth, and free from defects such as sand holes, shrinkage voids, cracks, residual risers, etc., and any sand sticking to the surface should be thoroughly cleaned off.

Stamped parts must not have burrs, cracks, oxidation, or other defects.

The effective height of each weld should meet the specified requirements, with welds being full and weld flux being cleaned off. There should be no incomplete penetration, slag inclusion, undercut, cracks, or other defects. For items like climbing ladders, it’s important to check the welding for solidity and firmness. You can tap them with an iron rod, and experienced workers can judge the quality of the welds by the sound they make.

Adjustable bases should be painted or cold galvanized on the surface, and the coating should be even and durable.

The surface of scaffold pole components and other structural parts should be hot-dip galvanized, with a smooth surface and no burrs, droplets, or excess clumps at the joints.

Measuring Data

In addition to looking at the appearance, you can also use tools to actually measure whether the wall thickness and weight are up to standard:

When selecting, you can use vernier calipers to measure the wall thickness of the scaffolding pipe and discs, etc., to detect whether the product is up to standard, and products that do not meet the standard have poor load-bearing capacity and are easy to break.

Socket Base Quality Control

Conclusion

The ringlock scaffolding, as a crucial component of the plug-in type scaffold, serves to connect the horizontal bars and vertical poles, forming a stable structure under three-point force. If there are issues with the quality of the ring-lock, it could lead to serious safety accidents during scaffold assembly and construction! Therefore, when selecting button scaffold products, one must not blindly pursue cheap prices while overlooking quality issues. Remember, you get what you pay for. After all, products that are both high-quality and affordable are quite rare.

Furthermore, apart from choosing high-quality ringlock scaffold products, it’s essential to adhere to scaffold erection standards and operate correctly, strictly prohibiting unauthorized commands and construction. This forms the basis for ensuring safety on construction sites. With years of experience exporting scaffolding, APAC welcomes all inquiries from our engineers. We’re here to address all your concerns.