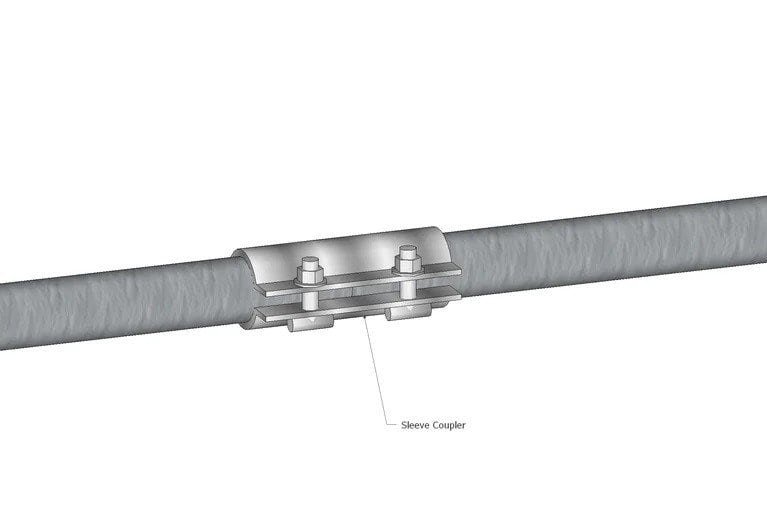

Scaffold Sleeve Coupler

A scaffold sleeve coupler, also known as a joint pin or spigot pin, is a type of scaffold fitting used to connect two scaffold tubes end-to-end in a straight line.

At APAC, we are committed to providing top-quality scaffolding components that meet the highest safety and performance standards.

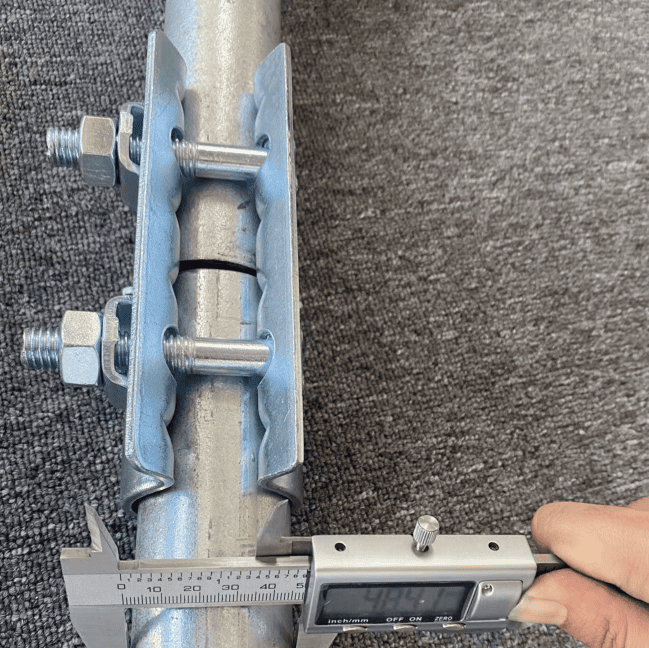

- For 48, 48.3mm O/D tube

- Galvanized for long service life

- Complies with EN74/BS1139 standards

- Pressed, drop-forged type available

- High-Quality Q195 / Q235 / Q355 Steel Material

Various Scaffold Sleeve Couplers For You

We offer different styles of scaffolding wheels to suit different scaffolding needs. We can also customize them to suit your needs.

Drop Forged Sleeve Coupler

- Material: Q235

- Standard: EN74/BS1139

- Weight: 0.58kg

Pressed Scaffolding Sleeve Coupler

- Material: Q235

- Weight: 0.98-1.0kg

- Size: 48.3×48.3mm

Galvanized Sleeve Coupler Clamps

- Material: Q235 Steel

- Standard: BS-1139/ EN-74

- Diameter: 48.3*48.3mm

Electro Galvanized Sleeve Coupler

- Material: Q235

- Standard: BS1139, JIS

- Type: Double and swivel

Advantages of APAC Scaffold Sleeve Couplers

APAC’s scaffold sleeve couplers offer a range of advantages that make them the preferred choice for construction professionals around the world. Here’s why our sleeve couplers stand out:

- Secure and Reliable Connections

APAC scaffold sleeve couplers are designed to create secure, end-to-end connections between scaffold tubes. This design ensures that the tubes are tightly joined, preventing slippage and maintaining the continuity of the scaffolding system. The reliable connections provided by our couplers enhance the structure’s overall stability, reducing the risk of accidents and ensuring worker safety. - Easy Installation

They require minimal tools and can be quickly installed, saving valuable time on the job site.

- Surface Treatment

APAC scaffold sleeve couplers are zinc-plated, providing superior resistance to rust and corrosion. This zinc plating extends the lifespan of the couplers, making them ideal for use in a variety of environmental conditions, including harsh outdoor settings. The enhanced durability ensures that your scaffolding system remains secure and reliable over extended periods, reducing the need for frequent replacements and maintenance.

- Customizable Branding Options

APAC offers customizable logo options on all our scaffold components, including sleeve couplers. This customization allows companies to maintain a professional and consistent brand image across all their equipment, enhancing recognition and trust in their brand.

- Compliance with European Quality Standards

Our scaffold sleeve couplers are manufactured to meet the rigorous European Quality Standard EN74. This certification guarantees that our products adhere to strict quality and safety benchmarks, providing peace of mind to our customers. The EN74 standard is recognized internationally, ensuring that our couplers are suitable for use in construction projects across the globe. - Highest Levels of Quality Control

At APAC, quality control is paramount. Each scaffold sleeve coupler undergoes stringent testing to ensure it meets our exacting standards. By maintaining high levels of quality control, we ensure that every coupler performs reliably under the most demanding conditions, contributing to the overall safety of your scaffolding system.

Applications

Our scaffold sleeve couplers are incredibly versatile, with a variety of applications in the workplace. They can be used to secure scaffold tubes horizontally (such as ledgers), vertically (as standards), or diagonally (as diagonal braces). This versatility makes them an essential component for constructing robust and flexible scaffolding systems that can adapt to different construction needs and site conditions.