What Is Ringlock Scaffolding?

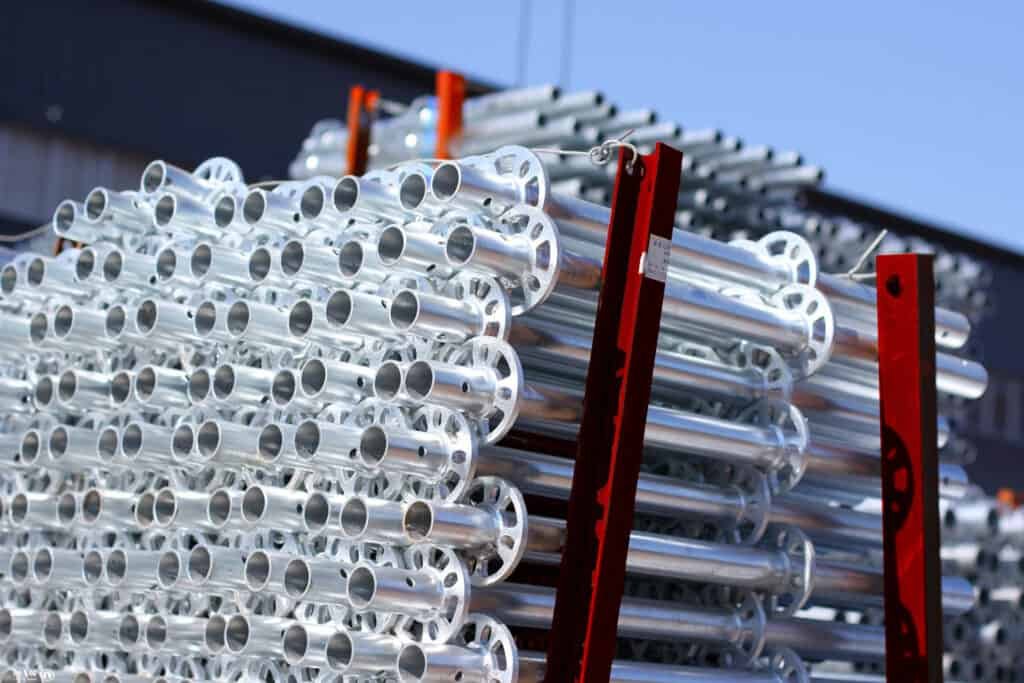

Ringlock scaffolding is a versatile, modular system designed for efficient, quick assembly. It uses a rosette connector to join horizontal, vertical, and diagonal components at multiple angles. Unlike traditional tube-and-coupler scaffolds, which rely on bolts and clamps, Ringlock uses a wedge-and-rossette system that is faster, safer, and more reliable. The system allows easy adaptation to various building shapes and heights, making it ideal for both simple and complex structures.

Core Concept:

Standards (verticals) have rosettes welded at fixed intervals.

Ledgers (horizontals) and braces connect into the rosette with wedge heads.

A hammer secures the wedge — no bolts, nuts, or spanners required.

Brief History:

Evolved in the late 20th century as an improvement over Cuplock and tube-and-coupler systems.

Designed to speed up erection, increase safety, and reduce component complexity.

Global Popularity:

Widely adopted in Europe, the Middle East, North America, and Asia-Pacific.

Favored in industries where projects are large, complex, and time-sensitive.

Key Features

Rosette Connector

- Allows up to 8 connections at different angles.

- Enables complex, multi-directional scaffolds (ideal for bridges, tanks, curved façades).

Modular Design

- Prefabricated standards, ledgers, transoms, and braces.

- Standardized components simplify logistics and assembly.

Tool-Free Assembly

- Wedge-and-hammer system.

- No nuts, bolts, or spanners required — reducing lost parts and speeding work.

Heavy Load Capacity

- Designed for heavy-duty projects with Safe Working Loads (SWL) tested under EN 12810/12811 and OSHA 1926.451.

Versatility

Works for straight, circular, inclined, or irregular structures.

Equally effective for façade scaffolds, shoring towers, or suspended scaffolds.

What Are the Advantages of Ringlock Scaffolding?

Ringlock scaffolding offers several key advantages that make it a popular choice for construction projects:

Advantage | Explanation |

Easy to Assemble | Fewer components make it faster and simpler to assemble compared to other scaffolding systems. |

High Load-Bearing Capacity | Strong enough to support heavy materials and equipment, reducing the need for additional support structures. |

Flexibility | Adaptable for both large and small construction projects, allowing modifications in height and structure. |

Cost-Effectiveness | Fewer parts mean lower overall costs, both in materials and labor. |

Durability | Hot-dip galvanized finish resists rust and corrosion, making it suitable for long-term use, especially outdoors. |

What Is the Material of Ringlock Scaffolding?

Ringlock scaffolding is primarily made from steel, usually Q355 steel, which is both strong and durable. It is often coated with hot-dip galvanization to protect it from corrosion, ensuring long-term use even in harsh weather conditions. Steel is the material of choice for scaffolding due to its strength-to-weight ratio, offering both stability and ease of handling.

Steel | Strong, load-bearing, and easily welded or fabricated for different configurations. |

Galvanized Steel | Resists corrosion, making it ideal for outdoor and high-moisture environments. |

Aluminum | Lightweight alternative — up to 30% lighter than steel. |

Surface Finishes

Hot-dip galvanization: Ensures long service life and resistance to rust, especially in coastal or industrial environments.

Powder coating: Adds branding options and additional corrosion protection.

What Are the Sizes of Ringlock Scaffolding?

Ringlock scaffolding components come in a variety of sizes to accommodate different heights and building types. The most common vertical post lengths range from 1.5 meters to 3 meters, while horizontal braces can vary depending on the span required for each project.

Size | Length | Use Case |

Standard | 1.5m, 2.0m | Most common, suitable for medium-sized structures. |

Extended | 2.5m, 3.0m | Used for taller buildings or larger platforms. |

Horizontal | Varies | Horizontal braces connect vertical posts and provide stability. |

What Is the Diameter of Ringlock Scaffolding?

The diameter of the vertical posts in ringlock scaffolding is typically 48.3 mm, which is the standard size for most scaffolding systems. This size strikes the right balance between strength and ease of handling, ensuring the scaffold can bear substantial loads while remaining easy to manage.

Component | Diameter | Use Case |

Vertical Posts | 48.3 mm | Standard size for most construction applications. |

Locking Mechanism | 48.3 mm | Consistent diameter for easy assembly and stability. |

What Is a Ring Lock Used For?

The ring lock is the central component of the system, used to connect the vertical posts and horizontal braces. It ensures that the components stay in place, forming a secure, stable platform. The locking mechanism allows for quick assembly and disassembly, making it ideal for projects that require flexibility and speed.

Component | Function |

Ring Lock | Secures vertical posts and horizontal braces together, forming a stable, reliable structure. |

Vertical Posts | Provide the primary load-bearing support for the scaffold system. |

Ringlock Scaffolding Applications

Ringlock scaffolding is used in a wide range of applications across the construction industry, from residential buildings to large-scale industrial projects. Some common applications include:

- Building Construction: Ideal for both small and large buildings, including multi-story projects.

- Bridges and Overpasses: Used for scaffolding on large-scale infrastructure like bridges and highway overpasses.

- Event Staging: Used in the construction of temporary stages for outdoor events and concerts.

- Maintenance: Perfect for use in industrial maintenance and repair projects, especially in hard-to-reach locations.

Ringlock Scaffold Catalogue

Looking for a detailed overview of all the components and specifications of Ringlock scaffolding? Download our Ringlock Scaffold Catalogue now to access comprehensive information on all available sizes, components, and technical details. This catalogue will help you choose the right materials for your next project and ensure you have everything you need for a safe and efficient scaffolding setup.

FAQs on Ringlock Scaffolding

What is the load capacity of Ringlock scaffolding?

The load capacity varies based on the configuration and components used but typically supports between 500–750 kg per bay. Always refer to the manufacturer’s load charts for accurate data.

Can Ringlock scaffolding be used for complex shapes?

Yes, Ringlock scaffolding is highly versatile and can be used for straight, circular, and inclined scaffolds due to its multi-directional connection system.

How quickly can Ringlock scaffolding be assembled?

The modular design and tool-free assembly allow faster erection compared to traditional scaffolding, reducing labor costs and project timelines.

Is Ringlock scaffolding safe?

Yes, Ringlock is OSHA-compliant and meets international safety standards. The system’s secure connections and modular structure provide enhanced stability and strength for workers at height.

How do I store Ringlock scaffolding?

Store dry, off the ground, and avoid exposing components to harsh weather for extended periods. Regularly check for rust or damage and repair components as needed.