What Are Scaffolding Couplers?

Scaffolding couplers are important parts used in construction to connect scaffolding tubes securely. They help create a strong framework that supports workers, tools, and materials at different heights during building and maintenance tasks. Understanding scaffolding couplers is crucial for keeping construction sites safe and efficient.

The main job of scaffolding couplers is to join scaffolding tubes together. This connection ensures that the scaffolding structure stays strong and can safely hold heavy loads without any accidents.

Scaffolding Couplers Materials

Scaffolding couplers are usually made from strong materials like steel or aluminum. Steel couplers are tough and good for heavy-duty work. Aluminum couplers are lighter and easier to handle but still strong enough for most jobs.

Choosing the right coupler and installing it correctly is very important for safety. Couplers must be tightened securely to prevent slipping or coming loose, which could cause accidents. Each type of coupler has a limit on how much weight it can safely hold. Not exceeding this limit is crucial to keep the scaffolding stable and safe.

Scaffolding Couplers Types

Scaffolding couplers are important in construction for securely connecting scaffolding tubes. They come in different types, each serving specific purposes to ensure safe and stable scaffolding structures. Here’s an overview of the various types commonly used.

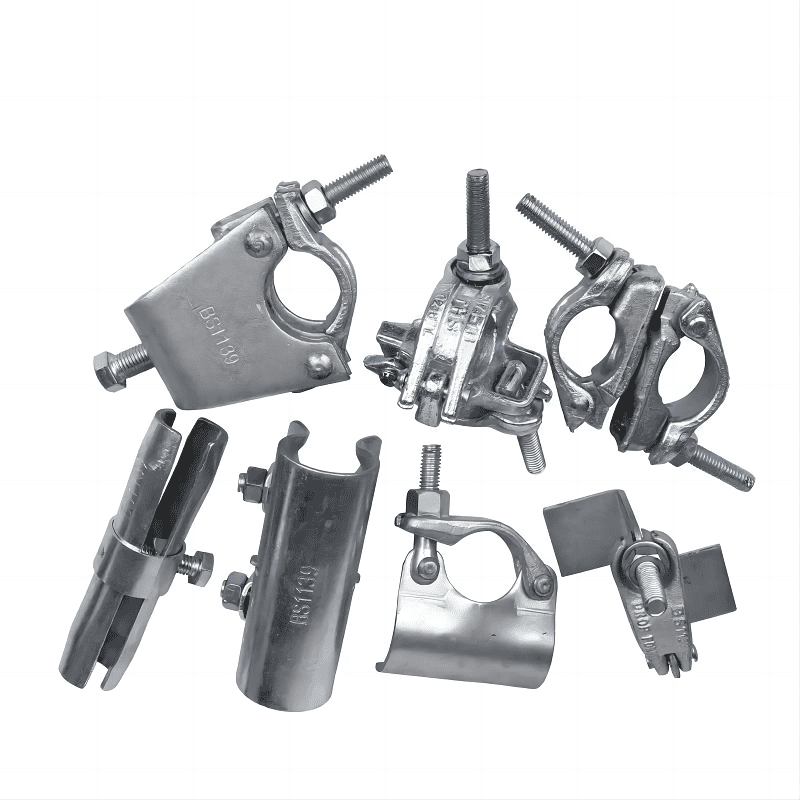

Swivel Couplers

Swivel couplers are versatile connectors that allow scaffolding tubes to join at different angles. They can rotate, which is useful for creating scaffolding setups with unique angles or configurations.

Right-Angle Couplers

Right-angle couplers, also called 90-degree couplers, are the most common type. They connect tubes at a right angle (90 degrees), creating strong, sturdy joints. These couplers are essential where tubes meet perpendicularly, ensuring the scaffolding remains firm and can support weight.

Sleeve Couplers

Sleeve couplers connect two scaffolding tubes end-to-end. They extend tube lengths securely, maintaining the scaffolding structure’s strength and stability. Sleeve couplers are used when longer tubes are needed without compromising safety.

Putlog Couplers

Putlog couplers, or single couplers, attach horizontal putlogs to ledgers or standards in scaffolding. They support the platform where workers stand, ensuring it stays safe and steady during construction activities.

Beam Couplers

Beam couplers, or girder couplers, connect scaffolding tubes to beams or girders. They provide additional support and stability, anchoring the scaffolding securely to existing structures.

Board Retaining Couplers

Board retaining couplers secure scaffold boards in place, preventing them from slipping. They ensure a safe and secure platform for workers to move on during construction tasks.

Joint Pin Couplers

Joint pin couplers connect scaffolding tubes end-to-end using pins that fit inside the tubes. They are easy to install and create a strong connection, supporting various construction needs.

scaffold swivel coupler

scaffold putlog coupler

scaffold board clamp

Sleeve Coupler Clamps

Scaffolding Couplers Maintance

Regularly inspecting couplers during use is essential. If any couplers show signs of wear, rust, or damage, they should be replaced immediately to prevent issues with the scaffolding structure, which could lead to serious accidents.

At the end of a project, it’s important to promptly collect the scaffolding couplers, categorize them, and store them in a dry, cool place (preferably indoors). Keep track of their quantity and usage for future projects.

In general, if scaffolding couplers are stored properly, they can be reused multiple times. However, it’s important to prevent rust; if any couplers show signs of rust, they should be removed and treated accordingly. It’s also advisable to conduct annual anti-corrosion treatments. Additionally, small components can easily be lost, so be sure to collect them promptly.

Scaffolding couplers Applications

Scaffolding couplers are crucial in construction for connecting scaffolding tubes securely. They serve several important purposes:

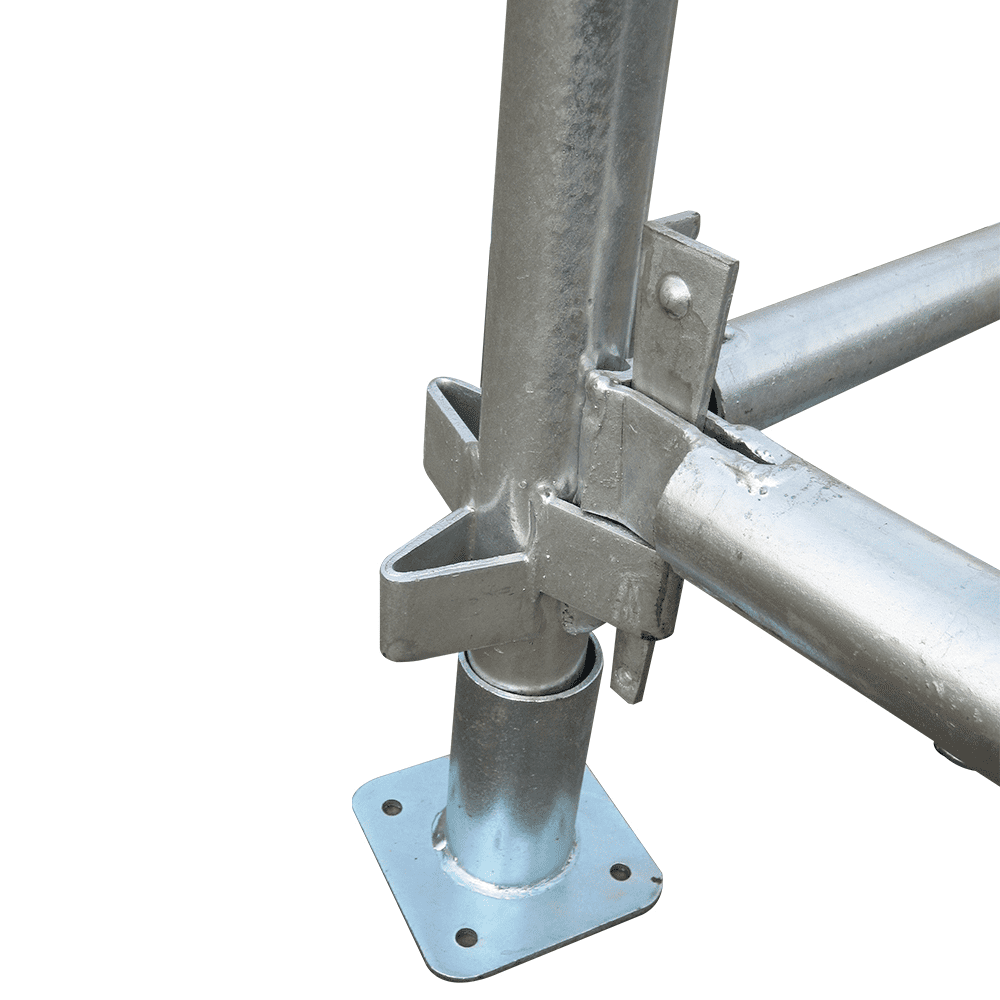

Supporting Structures

Couplers help build scaffolding frames that hold workers, tools, and materials at heights during construction, maintenance, or renovation.

Creating Platforms

They connect horizontal parts like ledgers and putlogs to vertical poles, forming stable platforms for workers to stand on safely.

Shaping Complex Structures

Couplers allow scaffolding to fit around odd shapes or obstacles by connecting tubes at different angles.

Securing Scaffold Boards

Board retaining couplers keep scaffold boards from slipping, ensuring a safe surface for workers to walk and work on.

Anchoring to Buildings

Anchor couplers hold scaffolding firmly to buildings or structures, preventing movement during windy conditions.

Connecting Beams

Beam couplers join scaffolding tubes to beams or girders, making the structure stronger and more stable.