Introduction

H Frame scaffolding is an essential component in the construction industry, providing a stable and secure platform for workers performing tasks at elevated heights. Known for its ease of assembly, durability, and cost-effectiveness, this scaffolding system is widely used in various industries, including building construction, infrastructure projects, and industrial maintenance. This guide explores the structure, features, applications, safety protocols, and global usage of H Frame scaffolding, offering valuable insights for professionals and contractors.

What is H-Frame Scaffolding?

H Frame scaffolding, as a widely used temporary support system, plays a crucial role in construction and maintenance projects due to its unique structural design and multi-dimensional advantages.

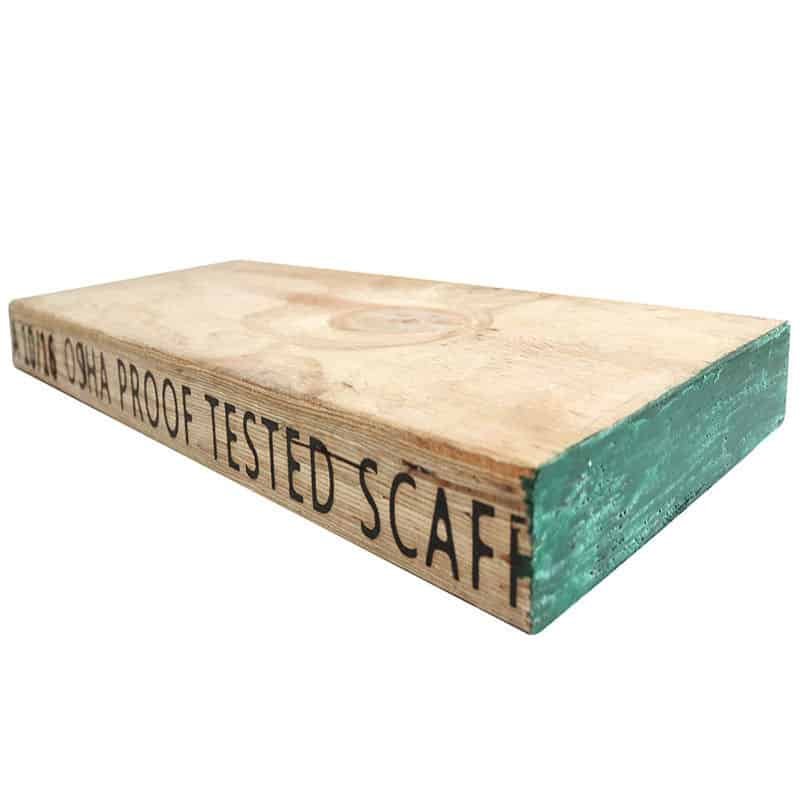

This scaffold features an “H”-shaped vertical frame as its core, connected by horizontal cross braces to form a stable load-bearing system. The frame is typically made of high-strength steel or lightweight aluminum alloy, ensuring durability and robustness, while the platform components are crafted from scaffold plank or plywood, balancing safety and practicality.

As a modular prefabricated system, H-frame scaffolding is renowned for its ease of assembly, allowing for quick on-site installation. It boasts excellent load capacity and spatial adaptability, ensuring worker safety at heights while accommodating diverse construction scenarios.

With its combined advantages of stability, cost-effectiveness, and flexibility, H-frame scaffolding has become the preferred solution for elevated work platforms in modern construction. It significantly enhances work efficiency and reduces project costs, making it an invaluable asset in the industry.

Main Components of H Frame Scaffolding

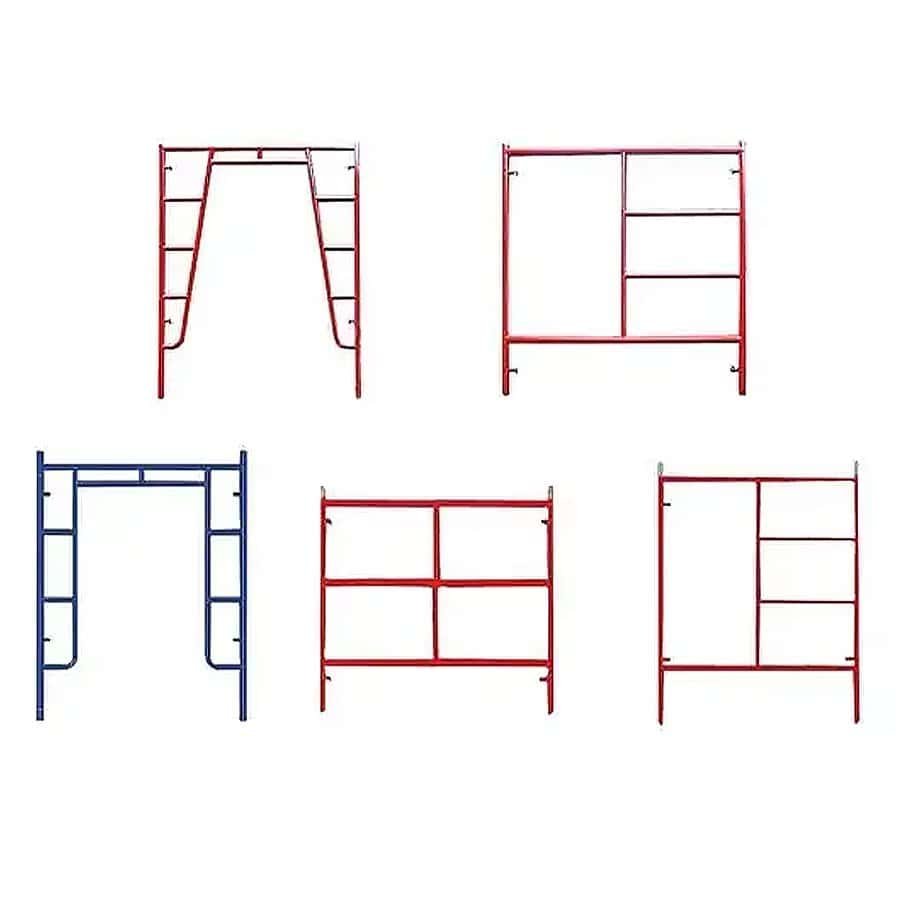

H Frame scaffolding comprises vertical H-shaped frames, cross braces, and horizontal ledgers. These components interlock to form a rigid structure that supports workers and materials at various heights.

H Frame scaffolding consists of several key components that work together to provide a stable and secure structure:

H Frames – The primary vertical structures that provide support and stability.

Cross Braces – Diagonal connectors that enhance rigidity and prevent movement.

- Horizontal Ledgers – Support beams that help distribute weight evenly.

- Base Plates – Positioned at the bottom to provide a stable foundation.

- Wood Planks/Plywood Platforms – Used as walkways for workers to stand and operate safely.

- Guardrails and Toe Boards – Added for worker safety to prevent falls and injuries.

- Joint Pins and Couplers – Connect different scaffold sections securely.

Key Features of H Frame Scaffolding

1. Fast Assembly and Disassembly

H Frame scaffolding is designed as a plug-and-play system:

Prefabricated frames, braces, and ledgers slot together with pins and simple locking mechanisms

No complex tube-and-coupler layout is required for basic bays

Less time spent measuring and aligning individual tubes

This simplicity reduces labor hours, erection time, and the risk of assembly errors—especially on repetitive building façades.

2. Versatile for Different Projects

H Frame scaffolding can be adapted for:

Building construction: masonry, cladding, plastering, painting

Bridge and infrastructure maintenance: access to piers, decks, and abutments

Industrial facilities: tank, pipe, and equipment access

Event staging: temporary platforms and stands where frame scaffolds are permitted

By varying:

Frame height and width

Number of lifts

Platform locations

you can tailor the scaffold to different building shapes and project requirements.

3. Durability and Load Capacity

Frames are typically made from:

High-quality steel (often hot-dip galvanized for corrosion protection), or

Aluminum alloy for lighter, easier-to-handle systems

When used according to manufacturer load tables and design limits, H Frame scaffolding provides:

Strong vertical load-bearing capacity

Good resistance to lateral forces when properly braced and tied

Long service life with proper maintenance

4. Cost-Effectiveness

Standardized, reusable components reduce long-term equipment cost

Simple geometry keeps design and erection time low

Ideal for contractors running repetitive residential or commercial building projects

Installation of frame scaffolding

The installation of H Frame scaffolding follows a straightforward process:

Base plates are positioned to ensure stability.

H Frames are connected using cross braces and ledgers.

Platforms and guardrails are added for worker safety.

Load tests and inspections are conducted to verify stability.

Technical specifications vary based on manufacturer and project requirements, including frame height, width, and material composition.

Applications of H Frame Scaffolding

H-frame scaffolding is commonly used in various construction and industrial projects.

- In high-rise building construction, it provides safe access for workers at different elevations.

- It is essential for bridge maintenance, offering a secure platform for repairs and inspections.

- In painting and plastering, it ensures stability for workers handling surface treatments.

- Additionally, it is widely used in shipbuilding, industrial facilities, and event staging, where temporary yet strong support structures are needed.

The system’s adaptability makes it an indispensable solution for tasks requiring elevated access.

Other Safety Consideration Tips

To ensure safe usage, H Frame scaffolding must comply with industry safety regulations such as OSHA, ANSI, and EN standards. These regulations define critical aspects, including load-bearing capacity, material specifications, and worker protection requirements.

Regular inspections should be conducted to identify potential hazards such as structural wear, loose connections, or damage to key components. Trained personnel must oversee the installation and maintenance process, ensuring that all safety protocols are strictly followed.

Proper worker training is essential for preventing falls and other accidents. Employees should be familiar with safe assembly procedures, weight limits, and emergency protocols. Additionally, the use of personal protective equipment (PPE), such as harnesses, helmets, and non-slip footwear, is crucial for minimizing risks.

Furthermore, scaffolding must be erected on a stable and level surface, with base plates and outriggers used to enhance stability. Load distribution should be carefully monitored to prevent overloading, which could compromise structural integrity. By implementing these safety measures, the risk of accidents can be significantly reduced, ensuring a secure working environment for construction personnel.

Conclusion

H Frame scaffolding is a crucial asset in construction, offering a balance of safety, durability, and ease of use. Its modular design, cost-effectiveness, and compliance with international safety standards make it a preferred choice across various industries and regions. Whether for high-rise buildings, infrastructure maintenance, or industrial projects, H Frame scaffolding provides a reliable and adaptable solution for working at heights. As global construction demands continue to rise, this scaffolding system remains an indispensable tool for ensuring efficiency and worker safety.

If you’re looking for high-quality H Frame scaffolding for your next project, consider consulting with a trusted supplier or construction expert. Stay informed about the latest scaffolding technologies and safety standards to maximize efficiency and safety on-site. Contact us today to learn more about how H Frame scaffolding can enhance your construction projects!