Loading Platform

A loading platform is a temporary or fixed working platform installed on a building edge or scaffold structure to safely load and unload materials at height (e.g., pallets of blocks, formwork, rebar, tools).

It creates a protected landing area where forklifts, hoists, or cranes can deliver loads, and where workers can receive, stage, and move materials into the building—while controlling fall risks and keeping the platform stable under designed load limits.

- 5,000 kg max service load for heavy-duty material transport

- Quick, pre-assembled delivery for fast on-site setup

- Vertical stacking capability for high-rise logistics

- Universal clamping system—anchoring through the slab or slab-to-slab pressure fit

- Integrated crane lifting points and forklift pockets for rapid repositioning

- Retractable drawer-type design (optional) for minimal site footprint

Technical Specifications of Loading Platform

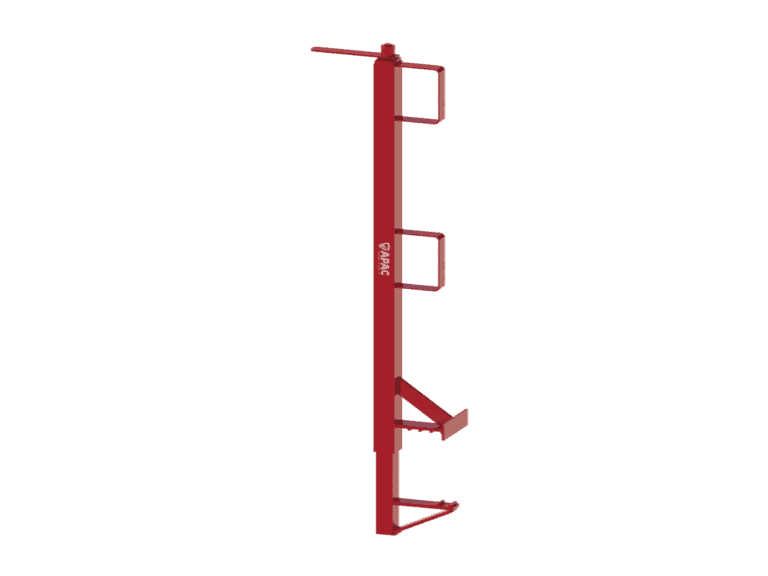

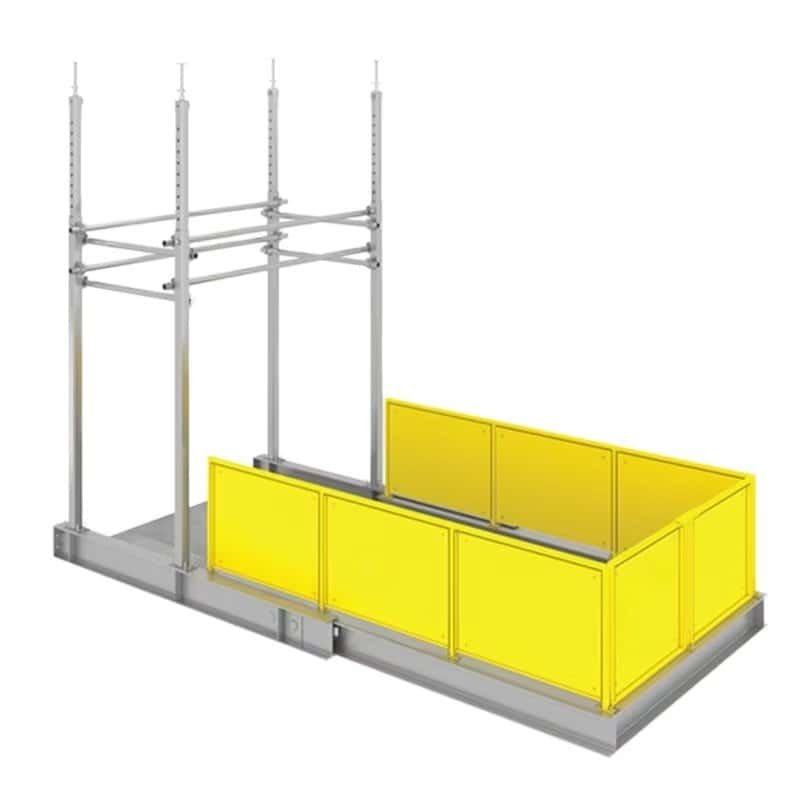

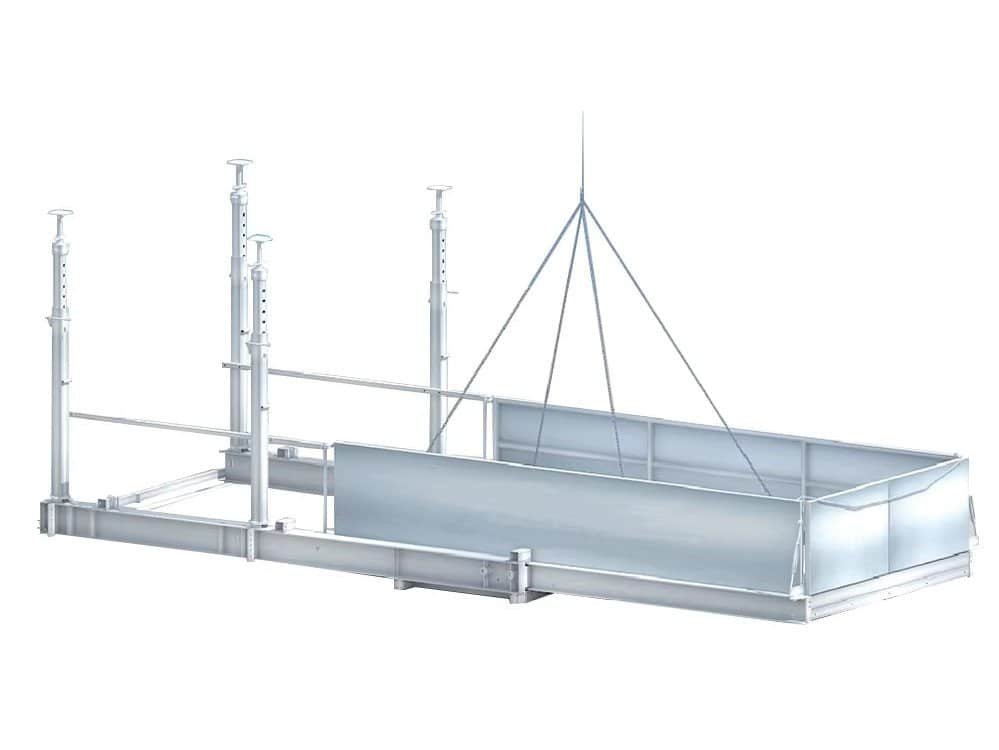

The APAC Loading Platform is a cantilevered, crane-liftable construction deck designed to safely transport tools, materials, and equipment across multiple floors on a job site. Built with galvanized, anti-slip chequer plate decking and a fully enclosed safety railing, the platform ensures optimal safety and stability at height.

| Specification | Detail |

| Platform Width | 2.95 m |

| Cantilever Length | 4.50 m |

| Maximum Service Load | 5,000 kg |

| Usable Deck Area | 10.9 m² |

| Dead Weight | 2,670 kg |

| Decking Material | Galvanised anti-slip chequer plate |

| Railings | Fully enclosed steel safety railings |

| Installation | Pre-assembled; pin-in-place side railings & props |

| Compatibility | Suitable for round and rectangular slabs |

Why Choose APAC Loading Platform

APAC loading platforms are built for predictable site performance—helping you move materials faster, reduce crane time waste, and keep loading zones controlled and compliant across multi-storey projects.

Heavy-Duty Load Capacity & Site Performance

Designed for demanding logistics on high-rise and concrete frame jobs, the loading platform handles heavy materials while keeping a practical working area for safe staging and transfer.

Up to 5,000 kg service load capacity

Suitable for steel beams, precast elements, formwork kits, MEP equipment, palletized materials

10.9 m² usable area with a jobsite-friendly footprint

Fast Setup & Faster Material Flow

APAC focuses on minimizing site handling. Units arrive prepared for rapid deployment, helping crews establish a working loading zone without long assembly time.

Pre-assembled delivery to site

Quick-ready setup: swing out rails/props + pin into position

Retractable “drawer” design enables vertical stacking, improving floor-to-floor material flow and reducing crane repositioning time

Safety-First Design for High-Risk Loading Zones

Loading areas are high exposure points. APAC loading platforms are engineered to control fall risk, improve footing, and keep the platform seated securely against the slab edge.

- Fully enclosed guardrails (all-around protection)

- Anti-slip galvanized decking for stable footing

- No-gap edge design to sit flush with the slab

- Secure fixing options: slab clamps or slab-through bolts

- Built-in crane slinging points and forklift pockets for controlled handling

Controlled Manufacturing & Export Delivery

APAC runs a structured delivery workflow to reduce common risks in cross-border supply—damage, missing parts, and inconsistent batches.

- Defined QC checkpoints from fabrication to final packing

- Export-grade packing for heavy steel items to lower transit damage risk

- Order tracking with milestone visibility from production to dispatch

Flexible & Universal Application of loading Platform

Engineered for versatility, the APAC loading platform can be deployed on:

- Rectangular or round structures (7 m radius and up)

- High-rise buildings under construction or renovation

- Demolition sites requiring temporary material staging

- Tight urban sites where ground-level space is limited

Its free positioning at the slab edge allows for greater adaptability, while the option to anchor through the slab provides extra structural security if needed.

Loading Platform | The FAQ Guide

1. What is a loading platform?

A loading platform is a purpose-built platform (often installed at a building edge or scaffold) that provides a safe landing area to load/unload materials at height by crane, hoist, or forklift, with guardrails and rated capacity.

2. What is a loading dock used for?

It’s used for safe, efficient loading/unloading at a building’s logistics interface—reducing manual handling, speeding turnaround, and improving traffic flow and safety.

3. Are loading platforms temporary works?

Yes—on construction sites, loading platforms are typically considered temporary works because they’re installed for a project phase and then removed or repositioned. They must be designed, installed, inspected, and used according to the project’s temporary works procedure and rated loads.

4. How much does it cost to put in a loading dock?

It depends heavily on dock type (new build vs retrofit), size, number of bays, pit or leveler type, door/seal systems, structural works, drainage, and local labor. In practice, costs can range from tens of thousands to hundreds of thousands (or more) per bay for a fully equipped commercial/industrial dock.