Introduction

APAC is a professional edge protection system supplier and manufacturer, all our products are factory direct. At APAC Builder Equipment, we have a team of experts who have dedicated themselves to providing the best possible Edge Protection System for our customers. Our Edge Protection System is designed to provide an extra layer of safety and security for a variety of applications, from construction sites to public areas. Our products are made from high-quality materials, ensuring their strength and durability, and are easy to install and use.

In this post, we will be providing you with an in-depth look at our factory, highlighting the production process of our Edge Protection System and the high level of quality control that we put into each and every product we produce.

Overview of the Factory

- Location

The factory is located in the Hebei province, a hub of industrial production in China. Our factory is easily accessible and has a favorable location that allows us to take advantage of the vast resources in the surrounding area.

- Production Process

The production process of our Edge Protection System is a multi-step process that includes powder-coated, manual coloring, and baking. We use state-of-the-art equipment and techniques to produce high-quality Edge Protection System products that meet the exact specifications of our customers.

- Quality Control

At APAC, quality control is of the utmost importance. Our team of experts inspects each and every product during each stage of the production process to ensure that our Edge Protection System meets the highest standards of quality and safety. We are committed to providing our customers with the best possible products, and our strict quality control process is one way in which we achieve this goal.

Production Process

- The powder-coated process

The powder-coated process is the first stage of production, where the mesh is sprayed with a high-quality coating. This whole process is fully automated and the coated color can be customised.

- The manual coloring process

After the spraying process, the manual coloring process begins. Workers use advanced spraying equipment and techniques to make sure that the mesh is of uniform color and free of any defects.

- The baking process

Finally, the mesh is baked in a high-temperature product line. This process gives the mesh a smooth surface and increases its strength and durability.

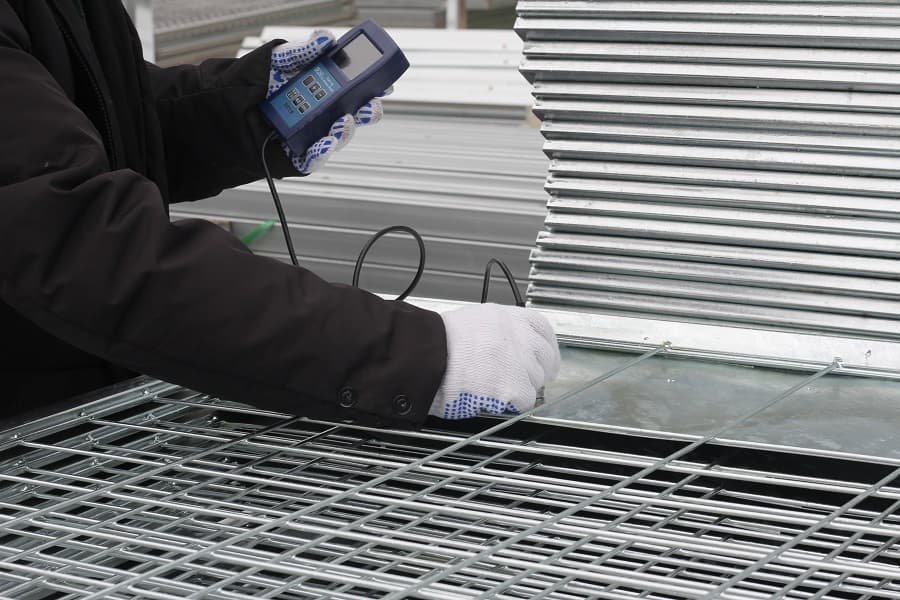

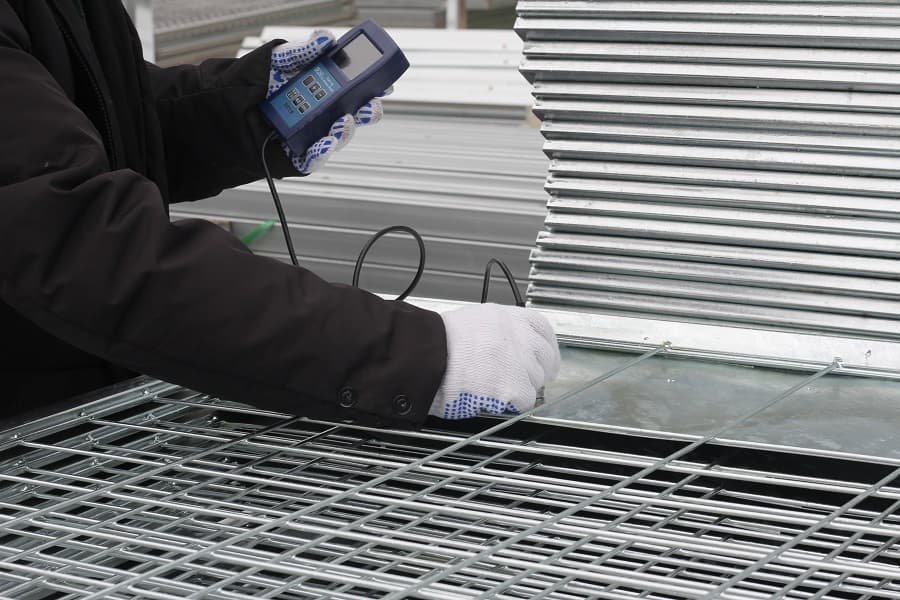

- The quality checks performed throughout the process

Throughout the production process, workers continuously conduct quality checks to ensure that the edge protection products meet our high standards. These checks include regular inspections and tests to verify the strength and durability of the products.

Advantages of the Factory Direct Edge Protection System

- Superior quality compared to competitors

Our edge protection products are made using high-quality materials and advanced production techniques, making them superior to those offered by our competitors. - Efficient production process

Our state-of-the-art factory and advanced production techniques allow us to produce edge protection products quickly and efficiently, ensuring that we can meet the needs of our customers in a timely manner. - Customizable options to meet specific customer needs

In addition to our standard products, we also offer customizable options to meet the specific needs of our customers. Whether you require a different size, shape, or color, our team of experts can help you find the perfect solution.

CONCLUSION

If you’re looking for a high-quality and durable edge protection solution, look no further than the APAC Edge Protection System. With its advanced production process, efficient delivery, and customizable options, you can trust that you’re getting the best products on the market.