grabber guardrail system

- OSHA and ANSI Compliant: Meets OSHA 1910.140, OSHA 1926.502, and ANSI Z359.18-2017 safety standards.

- Factory-direct supply: more competitive pricing and better cost control for repeat orders (no extra layers).

- Hot-dip galvanized and powder coating treatment, and any color can be customized.

What is Grabber Guardrail System

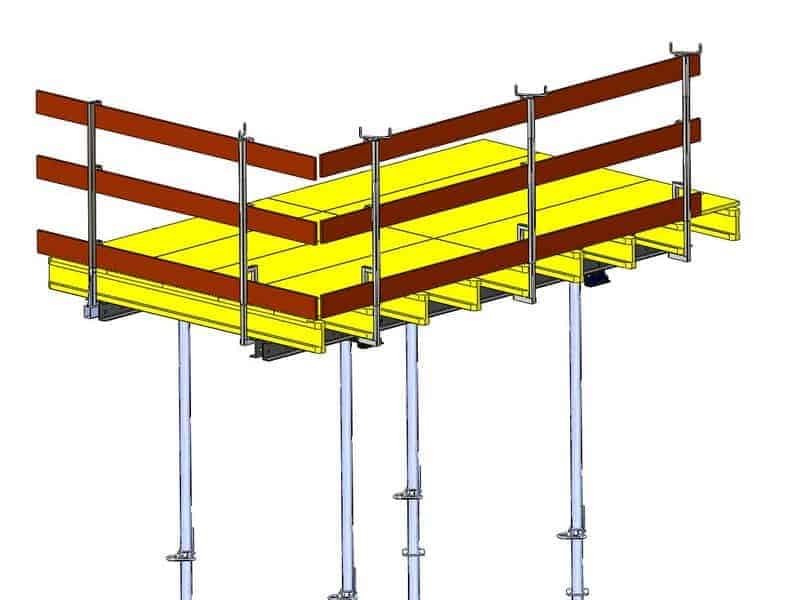

The Grabber guardrail system is guardrails with grabber clamp, it commonly adjustable to fit the thickness of most concrete slabs, providing temporary or permanent fall protection during construction. The system improves efficiency and saves labor and cost compare to others. Meanwhile, the grabber clamp is reusable, after setup, you can work safely at the roof edge.

Different types of grabber guardrail system

The difference between grabber guardrail systems is grabber clamp, the can be applied in different situations. You can choose the one that fit your project. They are usually hot-dip galvanized and powder coating treatment, and any color can be customized.

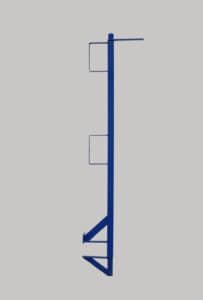

clamp on guardrail system

The clamp system complies with OSHA standards and provides a fast, safe guardrail solution for new construction slab or deck applications.

slab grabber guardrail system

Meets and exceeds OSHA standards. Manufactured with quality welds and durable steel. It is strong, durable, and reusable.

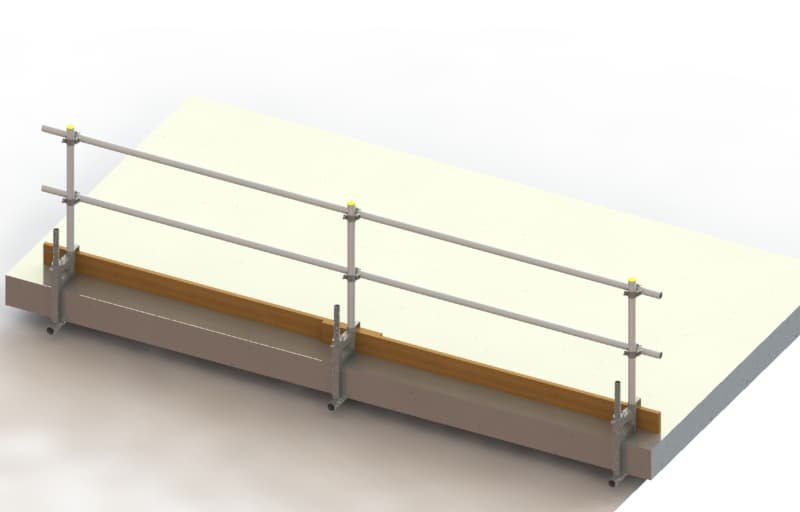

parapet wall guardrail system

Constructed with 5/8” Acme Screw inside for firm grip and clamp on to the wall. Will withstand horizontal loads in excess of 250 lbs.

parapet guardrail system

Easy to install, durable and non-corrosive. The Systems are available to accommodate steel railings or wood 2 x 4’s.

More About grabber guardrail system

We support your crew with both written and visual guidance to speed up deployment.

Detailed written installation instructions included

Online guidance with video tutorials and step-by-step demos

- Responsive support if questions come up during installation

Why Choose APAC grabber guardrail system

APAC’s grabber guardrail system is built for contractors and rental fleets that need fast, non-penetrating edge protection on concrete decking and parapet conditions—without sacrificing approval clarity or jobsite efficiency.

Heavy-Duty Design

The sturdy tube design is meant to withstand regular use and provide a long service life. The Slab Grabber is better shielded from the elements because there are no exposed adjustment rods or threads. For long life, all components are powder-coated.

- No need for tool installation.

- Ergonomic Large coated handle for ease of use and long life.

- The adjustable clamp can accommodate 2″ to 24″ slab.

- Integrated toe-board bracket.

Factory-Direct Pricing & Authentic Supply

Source directly from the manufacturer to reduce purchasing risk and keep budgets predictable.

No intermediaries, more competitive pricing

Consistent product quality from the source

Better control for repeat orders and long-term supply

Standards Alignment for Easier Site Sign-Off

Built to support jobsite compliance expectations for temporary guardrail setups.

Designed to meet applicable OSHA and ANSI requirements (when installed correctly)

Clear setup logic for rails/toe boards and spacing per site rules

Documentation support available for HSE/procurement review

Trusted by contractors worldwide

Applications of grabber guardrail system

A grabber guardrail system is ideal for temporary guardrails on concrete decking where you need reliable fall protection without slab penetration. Typical applications include exposed slab edges on multi-story builds, roof slabs, walkways, decks, and active floor perimeters during forming and stripping cycles.

Slab Grabber | The Ultimate FAQ Guide

1. What is a grabber guardrail system used for?

It’s used to build temporary guardrails on concrete slabs (and in some configurations parapet walls) to protect exposed edges on decks, walkways, roofs, and active floors.

2. Does this grabber guardrail system require drilling into the slab?

No. It’s a non-penetrating clamp design, so it grips the slab edge without slab penetration—helping avoid patching and concrete damage.

3. What slab thickness range can it fit?

Most jobsite “slab grabber” configurations commonly adjust from about 3″ up to 36″ (confirm your exact slab range and we match the right configuration).

4. What is the maximum spacing between posts?

The referenced requirement in the product specs is a maximum of 8 ft spacing (commonly aligned with OSHA guardrail layout practices).

5. What rails does the system support—wood rails or cable?

Typically it accommodates 2×4 and 2×6 wood rails, and some configurations also support cable or metal rail solutions. Tell us your preferred rail method and we’ll confirm compatibility.

6. Do I need a toe board with this grabber guardrail system?

Toe boards may be required depending on your jobsite risk and local rules. The system can support toe board mounting (commonly using a 2×4 toe board approach).

7. Does the grabber guardrail system meet OSHA and ANSI requirements?

The system is designed to meet applicable OSHA and ANSI requirements when installed correctly with proper rails, height, spacing, and toe boards as required. Documentation can be provided for review.

8. What do B2B buyers usually need for approval and ordering?

Most contractors/rental buyers ask for: slab thickness range, rail compatibility (2×4/2×6/cable), max spacing guidance, installation method, and a documentation pack (standards reference + usage instructions) to support HSE sign-off.