If you can recognize the H20 Beam, you will know that it is common to see these kinds of wood beams in construction worksite and it has been always safeguarding workers’ life safety. With an incredible outstanding capacity of load, it has gained popularity among construction contractor and construction equipment suppliers. In this article, we will give you a brief description of this type of wood beams to make you have a better understanding of the H20 Beam.

So what are you waiting for? Let’s dig into the article.

1. What is H20 Beam?

H20 beam, also called Timber Beam, is a type of concrete formwork wood beams mostly used in the construction industry. It has a very high load capacity and the lightest weight. You can apply it under a wide range of situations. Suitable for cuplock scaffolding, column formwork systems, girder wall, self-climbing systems, large-sized wall formwork of brqcket platform, roads construction&bridges construction, etc.

These H20 beams have higher durability and sustainability in different climate zones. Knowing the pros and cons of something can be very helpful in investing. We APAC offer the best quality H20 Beam, after reading this article, if you have any interest, please just contact us, we would be happy to offer you solutions.

2.Common Materials Of H20 Beam

Generally speaking, the material of the h20 beam is pine or spruce, of course, there are other wood materials, but Finnish spruce and radiata pine are the common materials.

● Finnish Spruce

Spruce is a lightweight material that is helpful when used for H20 beams. It is rot-resistant, stable, and an affordable wood material. It consists of an attractive and uniform structure with higher flexibility.

The density of Finnish spruce is 450 kg/m3. In the cold growing environment of Finland, the growth process of Finnish pine is slow and there are fewer problems with the moisture balance of the wood.

● Radial Pine

Pine is a renewable source for manufacturing H20 beams. Just like spruce, it is also relatively easy to work with. It consists of aesthetic and natural design.

Radial pine density of 400-500kg/m3, uniform structure, average shrinkage efficiency, high stability of high-quality softwood. The logs are highly permeable and extremely easy to handle such as anti-corrosion, drying, curing, and staining.

In comparison, radiata pine will be softer than Finnish spruce.

3. advantages of h20 beam

- SAFE

H20 beams give you higher strength and safety when using them on heavy-duty construction sites. lt possesses incredible dimensiona stability, Moreover, it has a higher recovery capacity after applying aheavy load.

- ECONOMICAL

Investing in H20 beams can be your most economical decision. The H20 beam elements can be assembled quickly and easily as well as the erection, compared with other alternatives, which saves a lot of labour cost.

- ADAPTABILITY

You can apply it under a wide range of situations. Suitable for cuplock scaffolding, column formwork systems, girder wall, self-climbing systems, large-sized wall formwork of brqcket platform, roads construction&bridges construction, etc.

- WATERPROOF

You have to notice that the surface treatment on your H20 beam makes it waterproof. For example, the APAC H20 beam is waterproof due to the yellow painting on its surface. With the existence of WBP phenolic glue, it is approved to fix the wooden structural components.

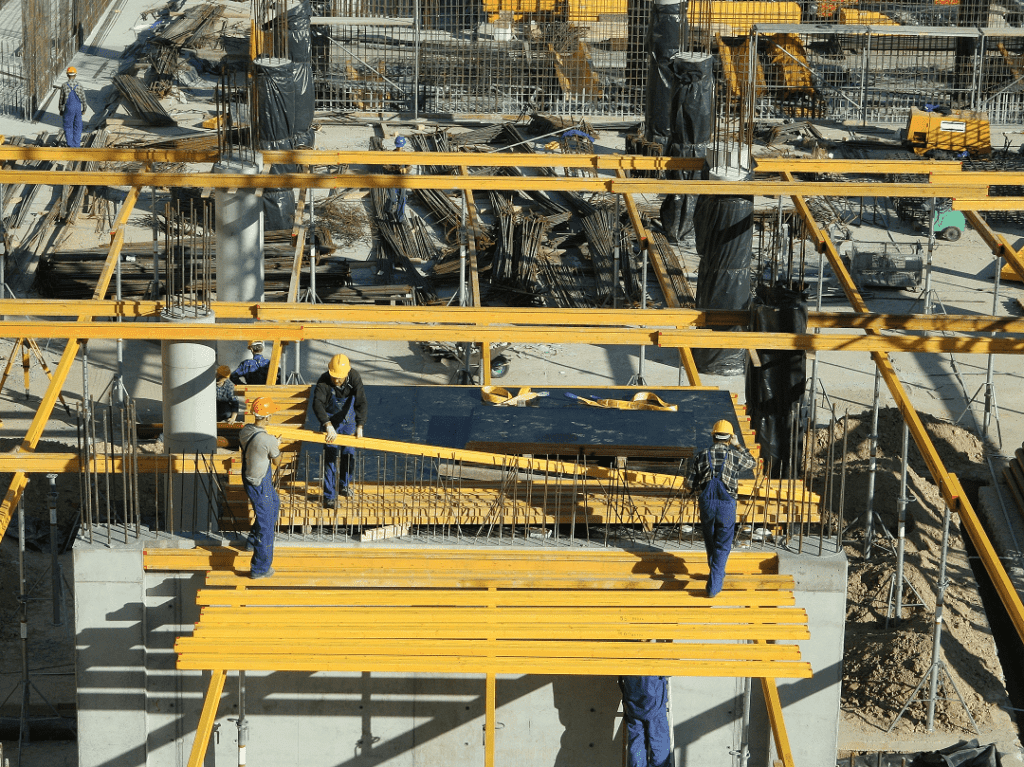

4. Applications Of H20 Beam In Construction Site

1. Column formwork systems

H20 beams are used as primary and secondary beams in column formwork systems. They provide stability to the structure and support the weight of concrete during the casting process.

2. Girder wall

H20 beams are used as girders in girder wall formwork systems. They provide horizontal support for the walls and prevent them from collapsing during the casting process.

3. Large-sized wall formwork of bracket platform

H20 beams are used as primary and secondary beams in large-sized wall formwork systems that require a bracket platform. They provide stability to the structure and support the weight of concrete during the casting process.

4. Self-climbing systems

H20 beams are used as primary and secondary beams in self-climbing systems. They provide stability to the structure and support the weight of concrete during the casting process.

6. Cuplock scaffolding

H20 beams can be used as horizontal struts in cuplock scaffolding to provide additional support to the scaffold structure.

7. Roads and bridges construction

H20 beams can be used in constructing roads and bridges as they can support heavy loads and span long distances.

5.Some Tips To Maintain H20 Beam

Some fantastic ways to take care of your H20 beams are explained in this article. These tips are:

- During Pouring Concrete

You should pour the concrete into the forms according to the fresh-concrete pressure limits. If you don’t follow the limits, it may cause breakage and deflection on your h20 beams.

- Be careful When Stripping Out The Formwork

According to experts, you should avoid stripping out the formwork until sufficient strength is attained. At the same time, the in-charge person should be allowed to strike the formwork.

You should never use a crane to break concrete cohesion when stripping out the formwork. Make sure you are not endangering the structure of the formwork when stripping out the formwork.

- Transporting, Stacking, and Storing Your Beams

You should use strap slings and not chains when transporting the H20 beams. When stacking the H20 beams, you should not exceed 2800kg per bundle. Moreover, the stacked H20 beams should not be affected by extreme climatic conditions. You should consider an inclination angle of 3% when stacking your beams.

It is also recommended that stacked beams be protected from extreme climate effects, such as exposure to sunlight or moisture, by covering (with breathable tarpaulins), which can reduce cracking. Cover them only, never wrap them completely, and always use spacers and spacers to ensure air circulation.

- Preventing The Effects Of Weather Conditions

- You should store your H20 beams under a roof to prevent harsh weather conditions.

- You can use spacers to dry the beam if it gets wet.

- There are more chances of fungal attack when higher humidity surrounds the beams. Try to keep them in a dry environment.

6.conclusion

In this article, we have introduced some knowledge about H20 Beam, I believe that you have already had a deeper understanding of H20 Beam. It is a good choice for construction worksite safety and it can guarantee workers safe and sound in the process of formwork construction project. And if you want to know more about formwork, you can click on our another two blogs on the right side to find out more information about formwork companies.

If you are looking for high-quality timber H20 beams supplier from China. Do not hesitate to get in touch with us, and our experts can provide professional advice based on your needs.