Introduction

If you are a new buyer of your scaffolding ringlock systems, then you must be suspicious about various things. Buying a high-quality Ringlock system from scaffold manufacture is a skill and you must be wanting to excel in that skill. You may also want to maintain ringlock scaffolding components after you are done with the purchasing process.

If you are facing problems figuring out all those facts and points, then this blog is the right place for you. Ringlock systems are capable of performing multifunctional tasks. This is why Ringlock scaffolding systems are prioritized over other modular scaffolding systems in construction projects.

We will help you out to reduce overall cost when using Ring lock scaffolding with amazing tips and tricks to maintain it.

However, if you have any other queries, you can also ask us through our website.

Main Components Of Ringlock Scaffolding System

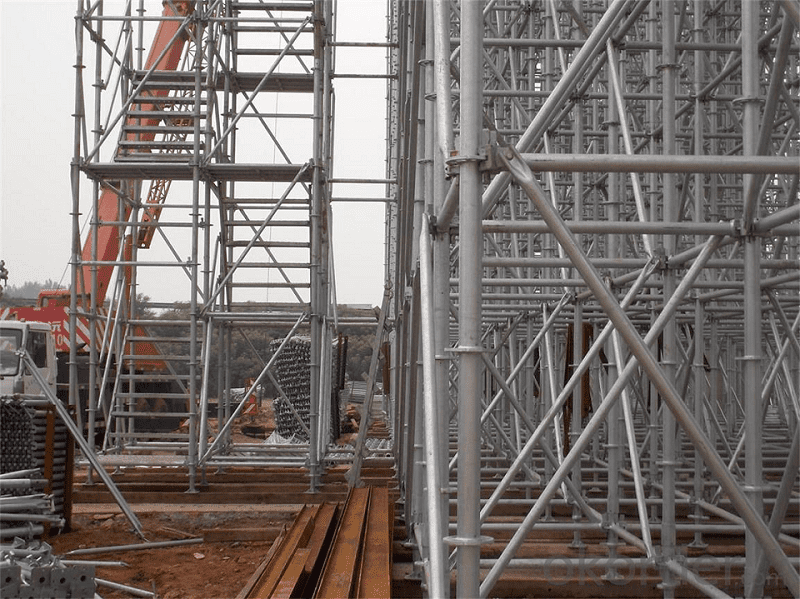

Ringlock scaffold products are highly durable to ensure protection for your large projects in the construction industry. The reason behind their popularity in various projects is their high load-bearing capacity. When dealing with highly complex projects, safety becomes important for the projects and their workers. Having amazing safety benefits as well as flexibility, Ringlock scaffolding systems are the best choice for your scaffold construction.

Like different items in this human world, Ringlock scaffolding components are likewise made out of various accessories. You can also customize your Ringlock scaffolding products but there are a few major parts that every system includes.

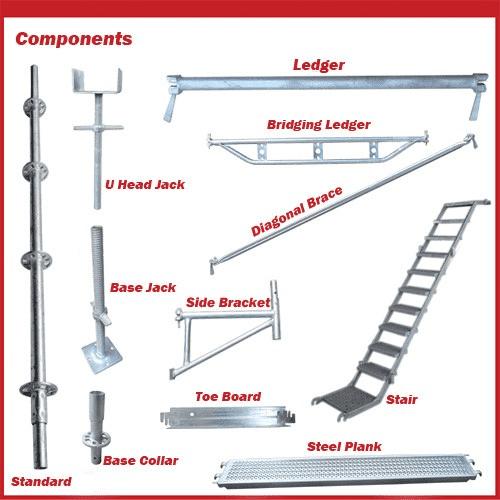

The important parts of your Ringlock scaffolding systems are listed as under :

- Adjustable Base jack, also known as a screw jacks:These sit at the bottom of the standards and provide adjustable height for the scaffolding structure. Base jacks are used to level the scaffolding on uneven ground.

- Standards with spigot, also known as upright and vertical: These are vertical tubes that form the backbone of the scaffolding structure. Standards are available in various lengths to accommodate different heights.

- Ledgers: These are horizontal tubes that connect the standards together and provide support for the platforms. Ledgers come in various sizes to suit different spans.

- Bay braces, also known as diagonal: These are diagonal tubes that help to stabilize the scaffolding structure and prevent it from swaying. Braces are available in different angles to suit different configurations.

- Ringlock Steel planks: These are steel boards that are placed on top of the ledgers to create a working platform for workers. Steel planks are non-slip and can be easily moved along the scaffold as needed.

- Truss ledger, also known as bridging ledger

Rosettes: These are the circular connectors that hold the standards, ledgers, and braces together. The rosettes have multiple locking points that allow for quick and secure assembly.

Full Production Flow Chart

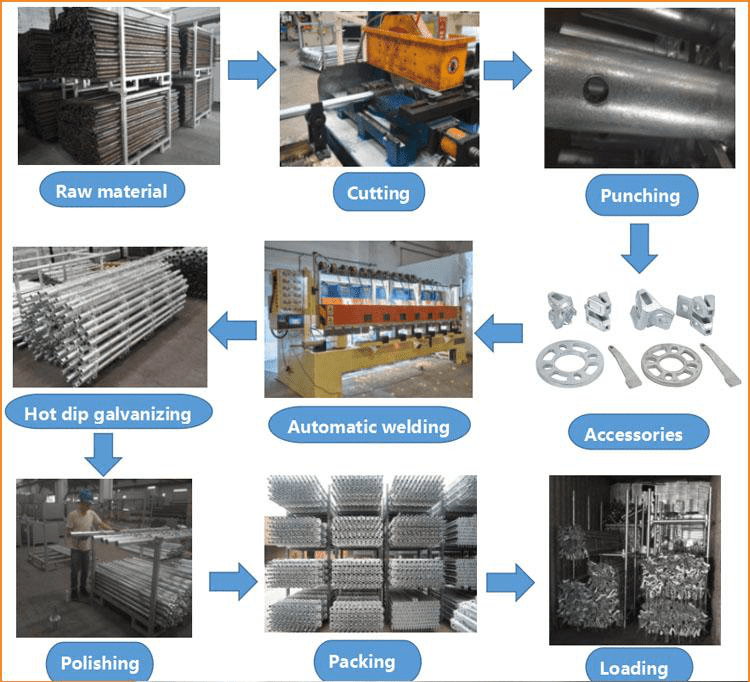

There is a proper process for the production of your Ringlock systems.

First of all raw material is collected. The steel tubes which are the raw material have to go through a cutting process. After the cutting process, punching takes place to give it a proper shape. The ringlock scaffolding manufacturers collect important parts or accessories that need to be welded.

The next step involves hot-dip galvanizing your punched and welded steel tubes. Lastly, polishing takes place that makes your scaffold products look better. After the Ringlock scaffolding system is completely manufactured, it is then packed and loaded for further supply.

Follow-up Inspection When The Hot-Dip Galvanized Is Erected

- The choice of the right scaffold system determines the efficiency as well as the quality of your large construction projects. APAC Ringlock scaffolding systems are highly reliable but our Ring lock systems also need maintenance to last longer.

Inspection plays an important role when you aim to achieve a safe environment for your working staff. It is recommended by highly qualified suppliers and manufacturers to inspect your Ringlock scaffolding system accessories before you start using them. There is a list given as under to help you inspect your Ringlock systems :

- First of all, you should make sure that all the accessories of scaffold system are secure and placed properly.

- The second step is to inspect whether your Ringlock scaffolding system has any dents in wooden or steel panels.

Regular inspections can help identify any defects, damages, or wear and tear that may have occurred during previous use.Inspecting Ringlock scaffolding system accessories involves checking for cracks, dents, deformations, corrosion, and missing components. It is essential to replace any damaged or missing parts before using the equipment.Your Ring lock scaffolding may also get damaged while overloading. It may cause bending of your scaffold systems. Make sure that there are no bends otherwise it will break. It is advisable to conduct inspections before each use and after any significant event that may have caused damage to the equipment.

You should make sure that the nuts on the braces and clamps of your scaffolding ringlock systems are able to move freely. For their proper maintenance, you can lubricate them so that they work better.

- In conclusion, regular inspection of Ringlock scaffolding system accessories is critical to maintaining a safe work environment for workers. It is important to follow the manufacturer’s recommendations and guidelines for inspection and maintenance to ensure the equipment’s longevity and safety.

If you have any further concerns or questions related to the inspection of your Ringlock scaffolding systems, you can immediately contact our professionals.

Maintenance Method Of Ringlock Scaffolding

While investing in the right equipment for large construction projects, the durability and functionality of the scaffold system play an important role. APAC Ringlock scaffolding systems have the ability to last longer without becoming unsafe or losing their functionality. However, if you want your product to last longer than the expected lifespan, you should perform proper maintenance. This will not only increase the lifespan but also the safety and security of your construction projects.

Regular inspection: Inspect the scaffolding system regularly to identify any damage or wear and tear. Look for cracks, rust, and missing or damaged components. Replace any damaged components immediately.

Cleaning: Clean the scaffolding system regularly to remove dirt, debris, and other contaminants that can cause corrosion. Use a wire brush to remove rust and a damp cloth to wipe down the components.Take necessary actions to avoid rusting of nuts and bolt threads. You can also make use of WD-40 to avoid rust.

Lubrication: Lubricate the locking mechanism of the rosettes with a silicone-based lubricant to prevent rust and keep the system functioning properly.

Storage: Store the scaffolding components in a dry and secure location when not in use. This will prevent damage from weather conditions and theft.

Training: Train workers on how to correctly assemble and disassemble the scaffolding system to prevent damage and injuries.

If you want help from any professional or expert, our suppliers are available 24/7 to give you the advice to maintain your Ringlock scaffolding systems.

Conclusion

Purchasing a Ringlock scaffolding system requires some knowledge before the purchasing process. When you are a new purchaser, you may find it difficult to choose the right modular scaffold products for your project. However, APAC has solved this problem for you.

You can follow the inspection methods and maintenance tips explained in this blog. It will help you to extend the lifespan of your ringlock system, thereby reducing the cost of repurchasing

If you have any further queries, you can contact us through our email. Our experts are always available to help you solve your problems.