Introduction

conclusion

In summary, LVL, LVB, and LVD are terms related to different wood-based materials. LVL is a well-known engineered wood product made by layering veneers in a specific orientation, offering superior strength and stability. LVB pertains to core structures within wood-based panels that are not specifically LVL or normal plywood. However, it is not a widely used industry term. Lastly, LVD, although occasionally mentioned, is not a commonly recognized term and is often used interchangeably with normal plywood.

Understanding these differences can help you better navigate the world of wood-based materials and make informed decisions for your woodworking projects. Whether you’re constructing door frames, beams, or furniture, selecting the right material is crucial for achieving optimal results.

When it comes to wood-based materials, there are several terms that may sound similar but actually refer to different products. In this blog post, we will explore the differences between LVL (Laminated Veneer Lumber), LVB (Laminated Veneer Board), and LVD (Laminated Veneer Density) plywood. Understanding these distinctions can help you make informed choices for your working projects.

LVL PLYWOOD - Laminated Veneer Lumber

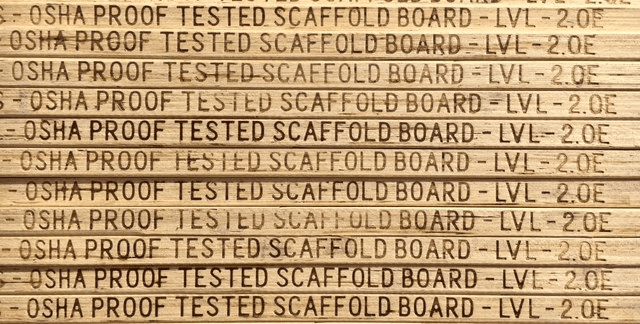

LVL, which stands for Laminated Veneer Lumber, might sound like a mouthful, but it’s a type of engineered wood product commonly used as a substitute for solid timber. It is made by thin layers of wood and sticking them together with a special glue, all oriented in the same direction. This arrangement provides enhanced strength and stability compared to traditional solid lumber. LVL finds applications in door frames, beams, scaffolding boards, and packaging materials due to its dimensional accuracy and durability.

Main applications

- Construction and Structural Use:

LVL is commonly used in construction and structural applications due to its high strength and dimensional stability. It is often used as beams, headers, and rim boards in residential and commercial buildings. LVL’s superior load-bearing capacity and resistance to warping make it an ideal choice for supporting heavy loads and spanning long distances. - Door and Window Frames

LVL’s dimensional accuracy and stability make it suitable for manufacturing door and window frames. It provides excellent strength and durability, ensuring the longevity of these essential components in buildings. - Scaffolding Boards

LVL is widely utilized in the construction industry for making scaffolding boards. Its high strength-to-weight ratio and resistance to bending make it a reliable and safe option for supporting workers and equipment during construction and maintenance activities. - Packaging Materials

Due to its strength and stability, LVL is used in the production of packaging materials such as crates, pallets, and boxes. LVL packaging ensures the protection and safe transportation of goods, especially for heavy or fragile items.

LVB plywood - Laminated Veneer Board

LVB, or Laminated Veneer Board, is a term sometimes used to describe core structures in wood-based panels that are neither LVL nor normal plywood. The core structure of LVB can be customized according to the requirements of furniture makers. It allows for flexibility in selecting various wood types, plywood, or other materials for the core construction. However, it should be noted that LVB is not a widely recognized industry term and is not commonly used in the market.

Main applications

Furniture: LVB plywood is commonly used in furniture manufacturing. Its good bearing capacity and stability make it suitable for producing chairs, beds, tables, cabinets, and other pieces of furniture that require strength and durability. The flexibility of LVB plywood allows for intricate designs and shapes.

Door frames: LVB plywood can be used to construct door frames. Its stability and structural integrity make it a suitable material to withstand the forces applied to door frames, providing strength and longevity.

Cabinets and shelves: LVB plywood is often utilized in the construction of cabinets and shelves. It provides a sturdy and stable base for storing items and can support the weight of various objects.

LVD plywood - Laminated Veneer Decking

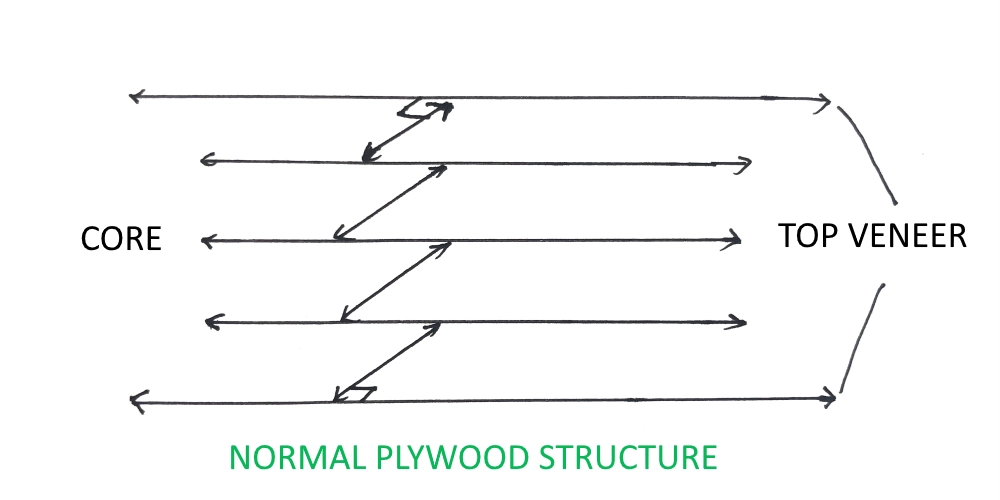

LVD, or Laminated Veneer Density, refers to the structural composition of normal plywood. In normal plywood, adjacent veneers are arranged perpendicular to each other, providing increased stability compared to solid timber. While some people may use the term LVD plywood, it is important to understand that this is not a widely recognized industry term, and normal plywood with perpendicular veneers is typically referred to as common plywood.

Main applications

With its outstanding features such as good bearing capacity and high stability, LVD plywood is commonly used in the manufacturing of flat furniture products. This can include tables, chairs, cabinets, and other furniture pieces where strength and stability are essential.