Introduction

Roof edge protection is an essential safety feature that every building with a roof should have. It refers to the installation of barriers or guardrails on the roof’s edge to prevent accidental falls and protect workers and other individuals from injury. These barriers can be permanent or temporary, depending on the type of building, the roofing system, and the nature of the work being done.

The importance of roof edge protection cannot be overstated, particularly in industries where workers need to access rooftops for various reasons. Whether it’s for maintenance, repairs, or installation of new equipment, working on a roof without proper protection is a recipe for disaster.

Falls from roofs can result in serious injuries, including broken bones, spinal cord damage, or even death. Therefore, it’s crucial to ensure that all workers who access rooftops are protected by appropriate edge protection systems.

The requirements for roof edge protection vary depending on the type of building and the nature of work being done. In general, there are three classes of roof edge protection, namely Class A, Class B, and Class C. Let’s explore all of these classes.

Class A

Class A edge protection systems are designed to withstand a force of at least 0.6 kN/m applied horizontally and 0.3 kN/m applied vertically. These systems are suitable for use in areas where there is a low risk of falling, such as at ground level or on a roof with a pitch of less than 10 degrees.

Requirements

- Class A edge protection systems must be capable of withstanding a horizontal load of at least 0.6 kN/m.

- Class A edge protection systems must be capable of withstanding a vertical load of at least 0.3 kN/m.

- Class A edge protection systems must be capable of withstanding normal wear and tear during use.

- These edge protection systems should be at least 1 meter high, measured from the working surface.

- Class A edge protection systems must be stable and securely anchored to the working surface.

- They should be able to resist any movement or displacement caused by external forces or by the weight of people leaning against them.

- Class A edge protection systems must be clearly visible, so that workers can easily identify their location and avoid accidental falls.

- These edge protection systems should be compatible with other equipment used on the worksite, such as scaffolding or ladders.

Class B

Class B edge protection systems are designed to withstand a force of at least 1.0 kN/m applied horizontally and 0.5 kN/m applied vertically. These systems are suitable for use in areas where there is a medium risk of falling, such as on a roof with a pitch between 10 and 30 degrees.

Requirements

- Class B edge protection systems must be capable of withstanding a horizontal load of at least 1.0 kN/m.

- Class B edge protection systems must be capable of withstanding a vertical load of at least 0.5 kN/m.

The rest of the requirements are similar to the class A edge protection systems.

Class C

Class C edge protection systems are designed to withstand a force of at least 1.5 kN/m applied horizontally and 1.0 kN/m applied vertically. These systems are suitable for use in areas where there is a high risk of falling, such as on a roof with a pitch greater than 30 degrees or where there is a risk of falling from a height of more than 2 meters

Requirements

- It must be capable of withstanding a horizontal load of at least 1.5 kN/m.

- Class C edge protection systems must be capable of withstanding a vertical load of at least 1.0 kN/m.

Common Roof Edge Protection Systems

Common roof edge protection systems include a range of solutions designed to prevent falls from roofs or elevated surfaces. These systems are often classified according to their suitability for different types of structures, such as concrete edges, steel structures, or formwork. Let’s discover some most common systems.

Edge Protection Systems for concrete edge

Edge protection systems for concrete edges typically consist of guardrails or barriers that are attached to the edge of the roof or elevated surface. These systems are typically designed to provide a permanent solution for areas where workers are likely to be present.

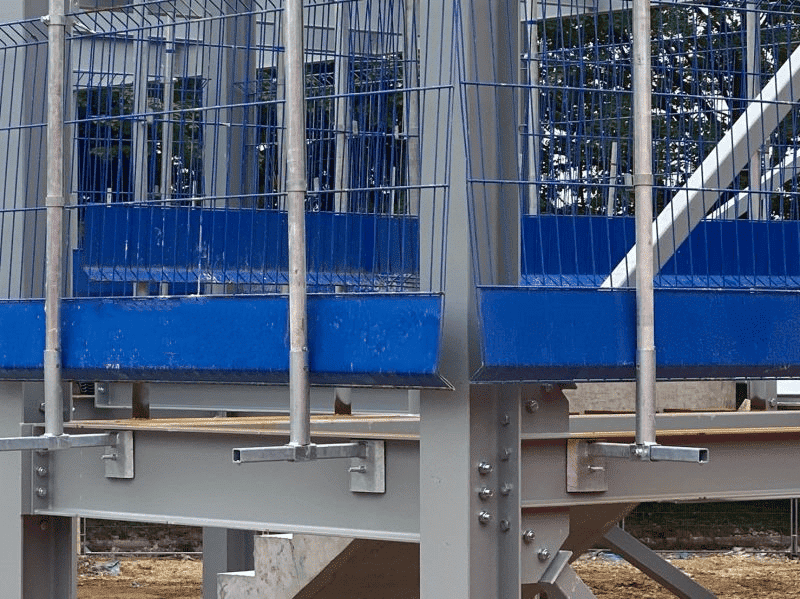

Edge Protection Systems for steel structure

Edge protection systems for steel structures often consist of clamps or other attachments that are designed to fit onto the steel framework of the structure. These systems are often used in areas where a concrete edge is not available, or where it is not feasible to install a permanent solution.

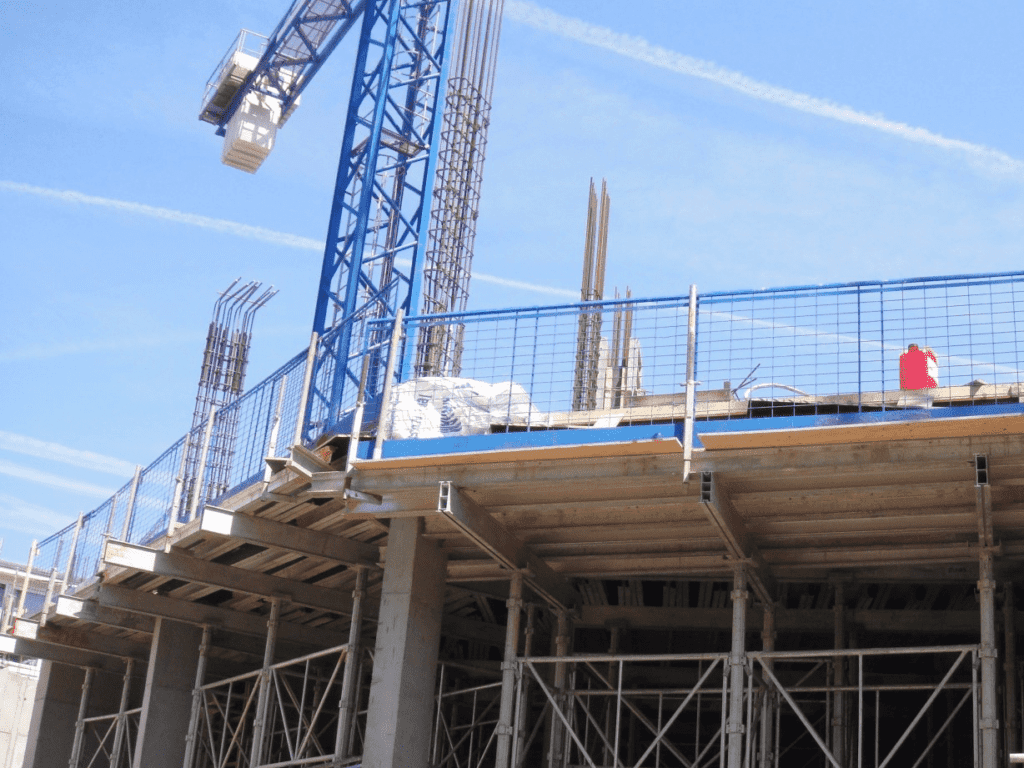

Edge Protection Systems for formwork

Edge protection systems for formwork typically consist of a range of components that are designed to fit onto the formwork or falsework used in the construction process. These systems may include guardrails, toeboards, or other barriers that are designed to prevent falls from the edge of the formwork.