Introduction

When you work at heights, whether it’s on a roof or a high-rise building, edge protection is essential to ensure your safety. An edge protection system is a set of barriers or guardrails that prevent you from accidentally falling off an elevated surface.

Edge protection systems are crucial in elevated work environments because falls from heights can be catastrophic. Even a fall from a relatively low height can result in serious injury or death. According to the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of work-related injuries and fatalities. Therefore, using edge protection is not just a best practice, it’s a legal requirement.

Types of Edge Protection Systems

When it comes to edge protection systems, there are several types available, and each has its unique characteristics and benefits. Depending on the type of work you’re doing and your environment, one system may be more suitable than another. Let’s take a closer look at four common types of edge protection systems: concrete, steel, stair, and formwork.

Concrete Edge Protection

Concrete edge protection systems are typically used in construction sites where the edge of a slab or floor needs to be protected. This type of system involves placing temporary barriers made of concrete on the edge of the structure.

Concrete edge protection is ideal for long-term projects where the structure will be in place for a while. The main advantage of concrete edge protection is its durability, but it can be challenging to install and requires a lot of space for storage.

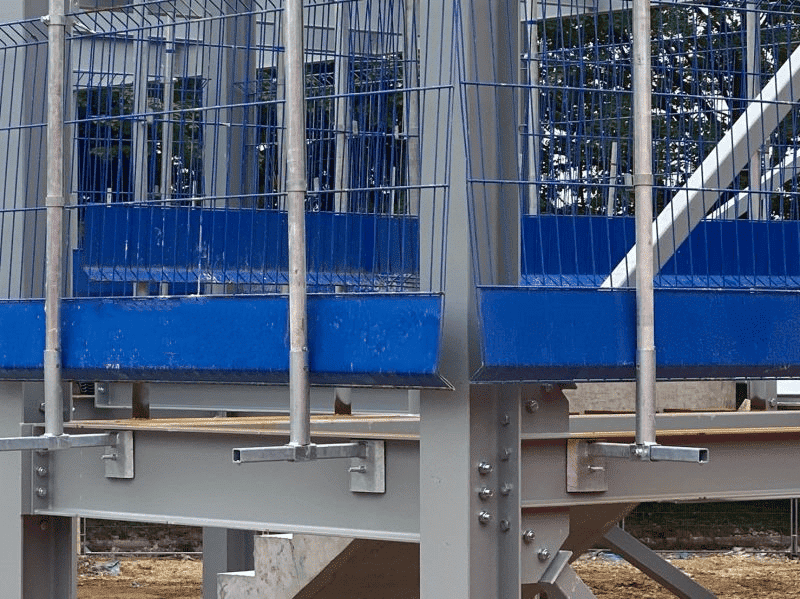

Steel Edge Protection

Steel edge protection systems are popular in construction, particularly in commercial and industrial settings. They involve metal barriers attached to the structure or the ground, providing a secure barrier for workers. Steel edge protection is easy to install and disassemble, making it an ideal option for short-term projects.

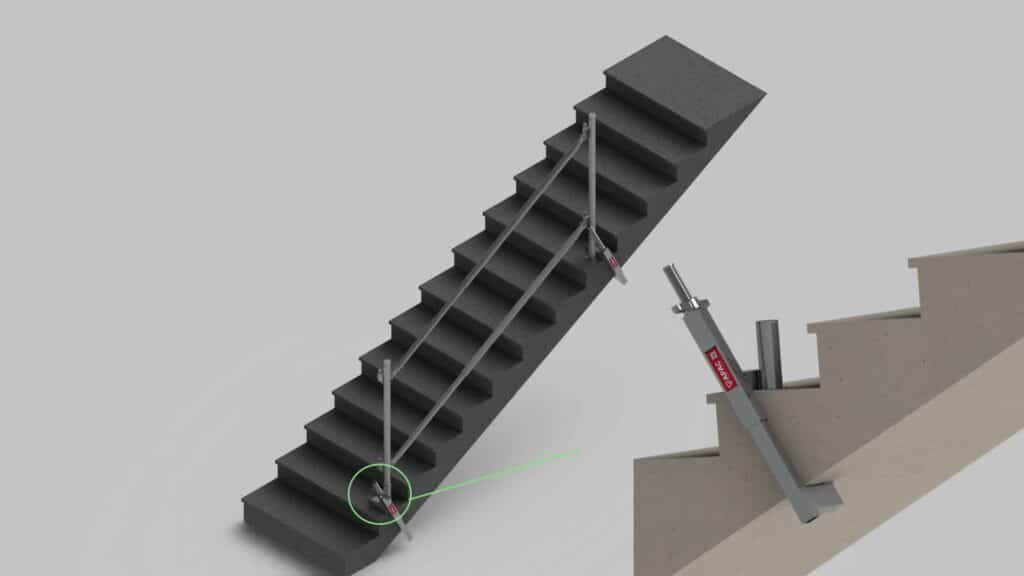

Stair Edge Protection

Stair edge protection systems are designed for use on stairways, where the risk of falling is particularly high. They typically involve installing guardrails or barriers on the edge of the stairs to prevent falls. Stair edge protection is easy to install and lightweight, making it an ideal option for short-term and long-term projects.

Formwork Edge Protection

Formwork edge protection systems are designed to protect workers on the edge of formwork, which is used to create concrete structures. This system typically involves installing temporary barriers or guardrails on the formwork to prevent falls. Formwork edge protection is ideal for long-term projects, but it can be challenging to install and may require a team to do so.

Safety Regulations and Standards

Safety regulations and standards are in place to ensure that edge protection systems meet specific requirements and are designed to provide adequate protection for workers at heights. Different regulations and standards apply to edge protection systems depending on where you are in the world.

In Britain and Europe, edge protection systems must comply with BS EN 13374. This standard specifies the requirements for temporary edge protection systems and is designed to ensure that the systems are installed correctly and provide adequate worker protection. Compliance with BS EN 13374 is required for all temporary edge protection systems used in construction and other industries in the European Union.

Australia and New Zealand: AS/NZS 4994.1:2009

The AS/NZS 4994.1:2009 standard applies to edge protection systems in Australia and New Zealand. This standard sets out the requirements for temporary edge protection systems and provides guidance on the systems’ design, installation, and maintenance. Compliance with AS/NZS 4994.1:2009 is required for all temporary edge protection systems used in construction and other industries in Australia and New Zealand.

USA: OSHA 1926.502 (Occupational Safety and Health Administration)

In the USA, the Occupational Safety and Health Administration (OSHA) regulates edge protection systems under 1926.502. This standard sets out the requirements for fall protection systems in the construction industry, including edge protection systems. Compliance with OSHA 1926.502 is required for all fall protection systems used in construction in the USA.

Materials and Customization

Regarding edge protection systems, durable materials are essential to ensure that the system can withstand the rigors of the work environment. Common materials for edge protection systems include steel 195, steel 235, and steel 345. In addition to durability, customization is also important to meet specific project needs. Edge protection systems can be customized to fit different structures, work environments, and project requirements.

Installation and Maintenance

Proper Installation to Ensure Effectiveness

- Drill the hole with 75 mm depth and 200mm distance from the edges.

- Install the socket base vertically into the position of the hole and tighten the screw bolt.

- Install the safety post to insert the socket base correctly.

- Install the mesh barrier vertically by unlocking the latch pin in the horizontal position.

- Overlap another mesh barrier and repeat the process.

Check out this video for details on the above process:

Regular Maintenance and Inspections

Proper maintenance of edge protection systems is crucial to ensure their effectiveness in protecting workers at elevated heights. Regular inspections, repairs, and replacements should be carried out as needed to keep the system in good working condition. Any damage or wear and tear should be addressed promptly to prevent accidents and ensure worker safety.

Training and Use

Proper training for workers is crucial when it comes to edge protection systems. All workers should be trained to use the edge protection systems correctly and safely. It’s also important to emphasize the importance of using edge protection systems at all times.

Even for simple tasks, the risk of falls and other accidents is high in elevated work environments. Therefore, workers should always wear the appropriate personal protective equipment and use the edge protection systems provided.

Conclusion

The edge protection system is crucial for ensuring the safety of workers in elevated work environments. The risk of falls and other accidents is high in these settings, and edge protection systems provide a critical line of defense against these risks. It’s important to ensure that edge protection systems meet your region’s relevant regulations and standards. By prioritizing safety and taking the necessary precautions, you can help prevent accidents.