Compression Post Edge Protection

- Personalized logos for your company’s products and compatibility with other brands.

- EN 13374 compliant edge protection, making it easier to approve the system and keep your perimeter protection audit-ready.

- Fast Installation & Labor Saving — The patented tightening/locking mechanism drastically cuts install time—often up to 5× faster—so you need fewer labor hours per floor.

Compression Post System

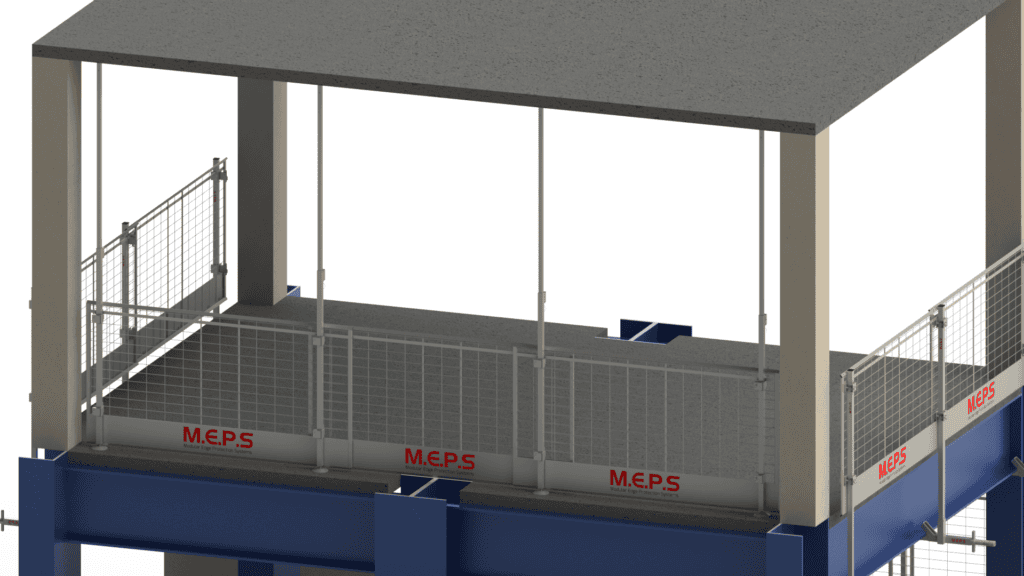

The compression post is a collective fall protection device that is used for securing edges between concrete slabs and other situations on construction sites. The system can be used in conjunction with edge protection barriers for full coverage. The toeboard of the mesh barrier prevents debris and material from entering or leaving the floor.

Components OF Compression Post

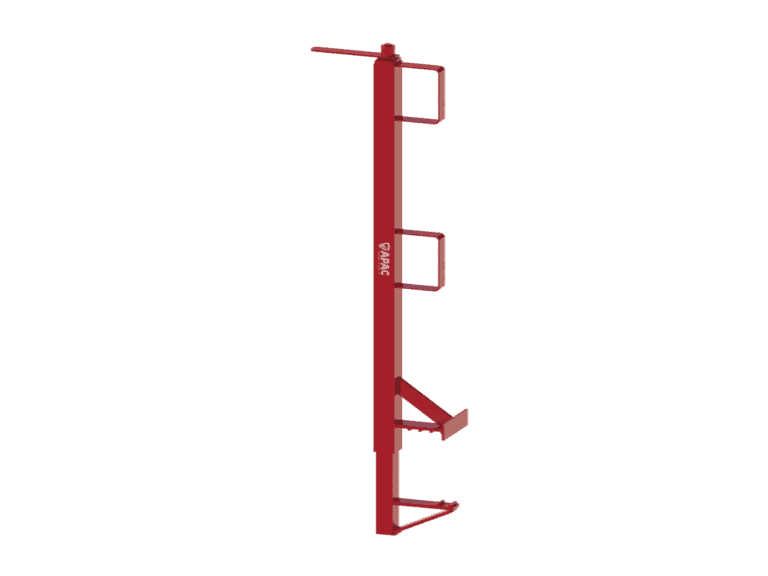

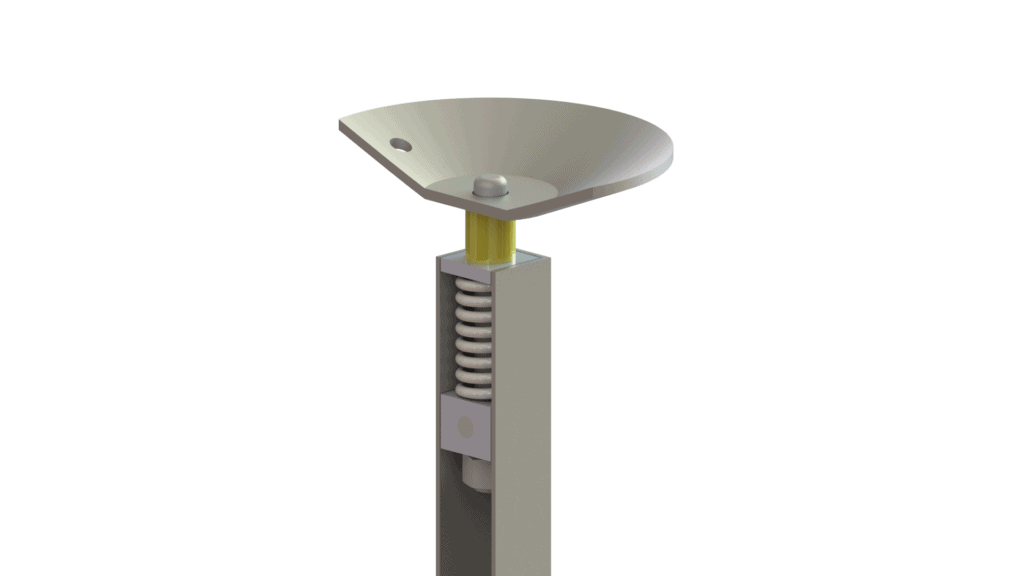

Compression

Post

Slab to soffit compression for heights between 2.4m (8′) to 3.5 m (11’6″).

Hot Dipped Galvanized.

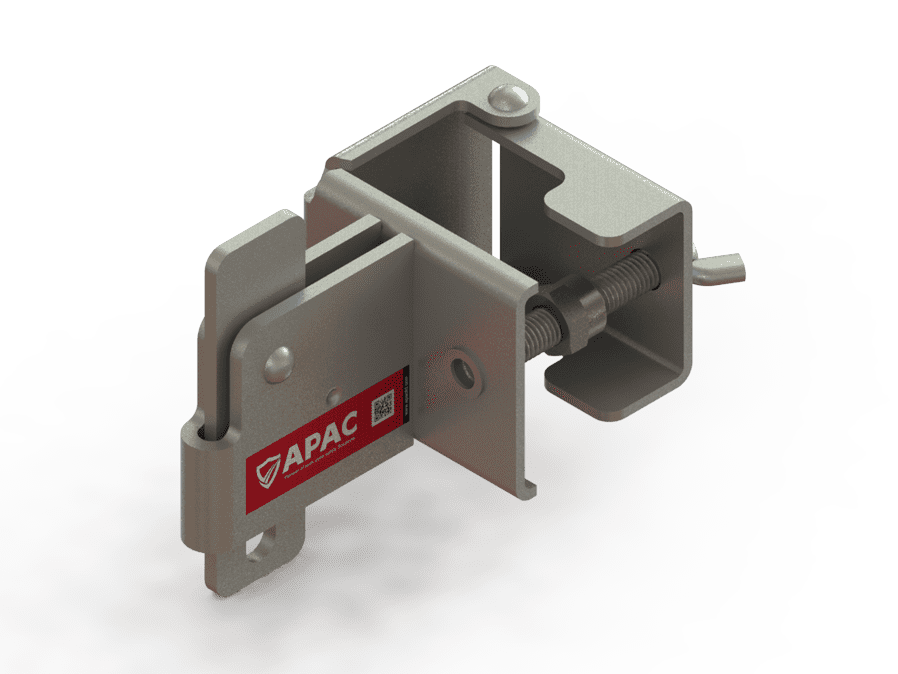

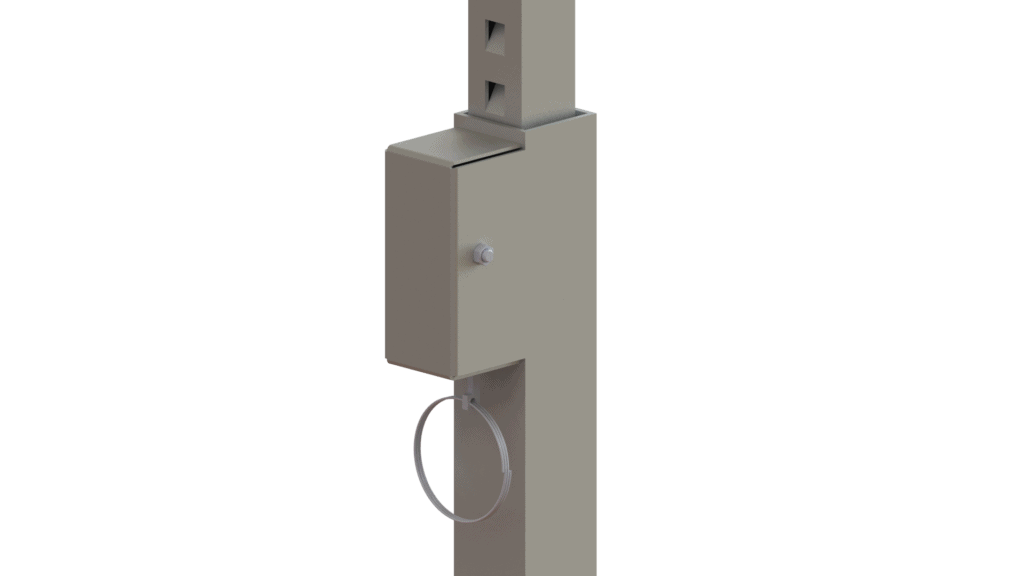

Compression Post Barrier Clip

The slider hook is a strong but light attachment can be adjusted to any position on the Post.

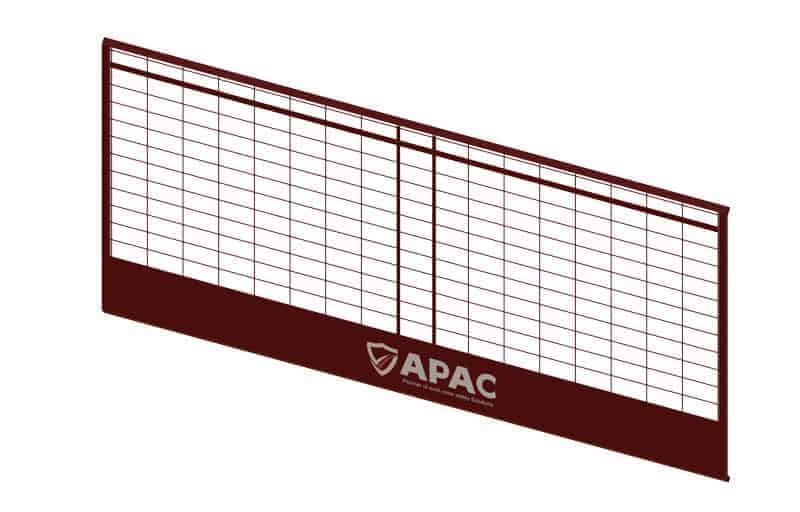

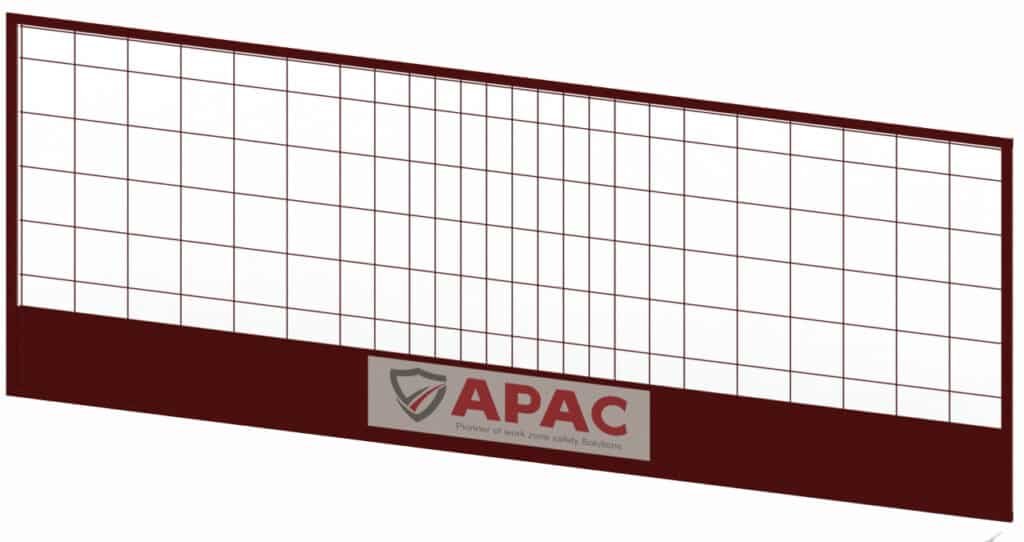

2.6m Safedge Mesh Barrier

1.2m high and 2.6m long. Galvanized mesh and frame, powder-coated for durability.

2.9m Safedge Mesh Barrier

1.1m high and 2.9m long with 4mm wire thickness. More lengths can be customized

More Information About Compression Post

The APAC Compression post can be fixed between concrete floors and soffits. No need drilling or anchoring, providing Safer and fast installation compression post edge protection for concrete floors.

The system is fully compliant with USA standards:

- OSHA 1926.502;

- European standard: BS EN 13374:2004;

- Canadian standard: Occupational Health and Safety Act of Ontario;

- Section 26. ONTARIO REGULATION 213/91;

- Australian standard:AS/NZS 4994.1 etc.

Why Choose APAC Compression Post

APAC compression posts deliver fast, drill-free edge protection for concrete-frame projects, with quick height adjustment, flexible barrier options, and support materials that make installation consistent across crews and sites.

Fast Fixing, No Drilling, No Tools

A quicker fixing principle than anchored/bolted methods—ideal when you need speed and minimal disruption on active slabs.

No tools required for installation

Faster setup and relocation vs. anchored/bolted fixing

Level indicator helps accurate vertical alignment

Four-step locking process for consistent on-site use

Built for Long-Term Use, Compatibility, and Branding

A durable, reusable system that supports multi-project efficiency while fitting broader fleet strategies.

Powder-coated steel for long-term use

Compatible with other brands (easier fleet integration)

Recyclable system vs. traditional guardrails for additional savings

Personalized logos available for your product line

Installation support: videos, PDFs, and engineer-led online guidance

Adjustable Height + Flexible Barrier Configurations

Designed for common floor-to-soffit ranges with barrier options to match your protection scope and site rules.

Quick height adjustment from 2.4 m (8 ft) to 3.5 m (11.5 ft) max

Works with barriers for practical height control

Choice of double-height or half-height mesh panels

Dense mesh options (50×50 mm / 150×75 mm) or customized meshes

Trusted by contractors worldwide

Applications of compression post

Compression post edge protection is most commonly used on concrete-frame projects where you need fast, non-drill installation and frequent repositioning as the job progresses. It can also be adapted for certain steel frame conditions depending on the fixing interface and project method statement.

Concrete slab edges & perimeters (RC frame floors, balconies, leading edges)

Temporary protection during pour cycles (move up floor-by-floor with the program)

Stair voids and floor openings (with double-height or full-height mesh panels)

Lift shafts / service risers (where a non-penetrating fixing approach is preferred)

Internal fit-out phases (keep edges protected without drilling into finished slabs)

Selected steel-frame applications (when suitable fixing provisions are available)

Compression Post | The Ultimate FAQ Guide

1. When should I choose compression posts instead of drill-and-fix?

Choose compression posts when you need fast installation, frequent relocation, or you want to avoid slab penetration (common on concrete-frame builds and fit-out stages). They’re especially useful when your program changes often and you need to move protection quickly.

2. Do compression posts require drilling or anchors?

Typically no—that’s the key advantage. They’re designed to fix between concrete floors and soffits without anchors, using a compression mechanism to hold position.

3. Can compression posts be used to fully protect openings (not just slab edges)?

Yes. Many systems can be configured with barriers plus containment netting to create fully covered openings, helping stop both people and loose materials from passing through.

5. What height range can compression posts cover?

It depends on the model—most are adjustable within a defined slab-to-soffit range, and some “XL” versions cover taller spans. Always confirm your project’s floor-to-soffit dimension against the manufacturer’s stated range.

6. Are compression post systems EN 13374 compliant?

Many compression-post solutions are tested/configured to EN 13374 (often Class A, sometimes A & B depending on the system and setup)—but compliance is configuration-specific (post + barrier type + height + fixing method). Ask for the test/technical documentation for the exact build you plan to use.

7. How fast is installation compared with drill-and-fix?

Many suppliers position compression posts as significantly faster because you eliminate drilling, dust, and anchor installation—plus relocation is simpler. Actual speed depends on crew experience, edge geometry, and containment requirements.