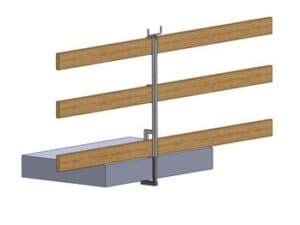

slab grabber handrail

A slab grabber handrail is a safety device designed to provide edge protection on concrete slabs during construction or maintenance work. It attaches securely to the edge of the slab to create a temporary barrier, preventing workers from falling off the edge of an elevated surface. Unlike other handrails, a slab grabber handrail typically features a clamping mechanism that grips onto the slab without requiring drilling or penetrating the concrete.

- Heavy-duty – Frame constructed from carbon steel.

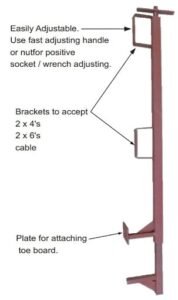

- Versatile – Easily attach 2X4’s or 2X6’s or string cable for perimeter guardrail barrier.

- Corrosion resistance – Hot Dipped Galvanized or powder coating surface provides an excellent finish and protection.

- Simple Install – Adjust the guardrail post open width and tighten only by the top handle rotating

- Meets and exceeds OSHA/ANSI Standards

More details about slab grabber handrail

| Material | Q235B |

| Surface treatment | Hot-dip galvanized or powder-coating |

| Standard | Meets or Exceeds OSHA 1910, OSHA 1926.502 (b) |

| Weight | 22 lbs |

- Ensure the slab decking and structure can support the system and installer before you install the guardrail system.

- Work surface surfaces must be free of debris, gravel, and loose or slippery concrete surfaces that could interfere with slab grabber bearings.

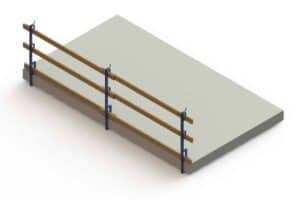

- Measure and space the location of each slab grabber, no more than 8 feet between each one, or more than 12 inches from any outside or inside corner.

- Rotated the top handle in a counter-clockwise motion to open the post clamp slightly larger than the desired slab decking thickness.

- Place the clamp over the slab edge and make sure the post is positioned perpendicular to the slab surface.

- Adjust the top handle to tighten in a clockwise motion until the grabber is secure on the concrete slab. If using a torque wrench, tighten no more than 30 lbs./ft.

- Place the 2” x 4”, 2” x 6” or cable through the top rail and mid rail space on the post, use nails to secure 2” x 4” or 2” x 6”.

- The 2” x 4” or 2” x 6” can be used as toe boards if needed. The process is the same as above.

- Clear up all dirt, corrosives and contaminnats on the surface of the slab grabbers after use

- Store the grabbers in a dry place that can not be affected by heat and other chemicals elements

- A formal inspection is needed every 6 months. Inspect for deficiencies including but not limited to corrosion, cracks, bent or damaged sections. Record the inspection results.

- The damaged units can be repaired ONLY by representative person or entity authorized ones.

Why Choose APAC slab grabber handrail

APAC is committed to delivering high-quality, long-lasting parapet clamp guardrail systems that not only meet but exceed industry safety standards, such as OSHA. Our guardrails are crafted from durable steel, and with precision welding, they are built to withstand demanding environments and ensure long-term safety on construction sites.

High-Quality Manufacturing with Durability in Mind

We have been manufacturing reliable products since 2014, with an unwavering commitment to quality and excellence. Our parapet clamp guardrail systems are designed to enhance worksite safety by providing a strong, secure barrier that can withstand tough conditions. The robust steel construction combined with quality welding ensures that our guardrails remain stable and durable, even in high-traffic or high-stress environments.

- Built to last with durable steel and quality welds

- Designed to exceed OSHA standards for maximum worker protection

- Withstands demanding environments and high-traffic areas

Customized Surface Treatment Options

APAC provides customized surface treatment options based on your specific project needs. Whether you require extra durability for outdoor projects or aesthetic finishes for indoor applications, we can tailor the surface treatment to match your requirements.

- Customizable surface treatment for specific needs

- Choose from powder coating or galvanization

- Tailored solutions for enhanced corrosion resistance and aesthetics

Proven Experience and Trusted Expertise

With over 10 years of experience in manufacturing quality safety products, APAC has earned a reputation for providing reliable, high-performance solutions. We understand the needs of the construction and industrial sectors and ensure that our products are engineered to deliver safety and reliability on every project.

- Over 10 years of industry experience

- Trusted quality assurance with ISO 9001 certifications

- Compliant with international standards such as OSHA and EN 12810

- Competitive pricing for high-quality products

- Exceptional customer service to support project needs

- Long-term value with low maintenance and lasting durability

Applications about slab grabber handrail

The slab grabber handrail is a versatile safety solution that prevents falls and increases worker safety across a wide range of construction, maintenance, and renovation projects involving concrete slab work. Its adjustable and easy-to-install design makes it an ideal choice for providing temporary edge protection in a variety of environments.

slab grabber handrail | The Ultimate FAQ Guide

1. What is a slab grabber handrail?

A slab grabber handrail is a temporary edge protection system used in construction to prevent workers from falling off elevated concrete slabs or scaffold platforms. The handrail attaches securely to the edge of the slab using a clamping mechanism, providing a stable barrier around the work area. It can be adjusted to fit different slab sizes and provides safe access for workers performing tasks at height.

2. How does a slab grabber handrail work?

The slab grabber handrail works by clamping onto the edge of a concrete slab or other surfaces using a secure clamping mechanism. Once attached, it forms a temporary safety barrier that prevents workers from accidentally falling. The handrail can be secured in place or locked in an open position to allow for easy access and movement.

3. What are the benefits of using a slab grabber handrail?

Prevents falls: The handrail provides edge protection to mitigate fall hazards on construction sites.

Increases safety: Provides a secure barrier that enhances worker safety during slab work.

Easy installation: Designed for quick and simple installation without needing to drill into the slab.

Adjustable: Can be customized for various slab thicknesses and heights.

Durable: Made from high-strength materials, making it long-lasting and reliable in tough environments.

4. Are slab grabber handrails adjustable?

Yes, slab grabber handrails are adjustable to fit a range of slab sizes and heights. This allows them to be used on different scaffolding configurations and construction setups, providing flexibility in various environments. The adjustability ensures that the handrail can securely fit the edge of any slab, reducing the risk of accidents.

5. How long do slab grabber handrails last?

The lifespan of a slab grabber handrail depends on the materials used and the environment in which it is used. High-quality materials like galvanized steel or aluminum can provide many years of reliable service. Proper maintenance, including regular inspections for damage or corrosion, will ensure that the handrail continues to function as a safe and secure edge protection solution for extended periods.

APAC BUILDERS EQUIPMENT LTD. has armed worksite safety professionals with best-in-class fall protection solutions in the past decade. With our safety experts engineering and testing our product lines rigorously following government laws, you can be confident you are getting the right solution to protect the people who need it most.

Count on our reliable customer service to deliver everything you need. “Leave No Doubt” is our motto when it comes to worker safety.