LVL Scaffold Planks

The LVL scaffolding planks are lightweight and high-strength materials used in the construction industry. They have waterproof characteristics, anti-corrosion, no deformation, non-warping, and many others suitable for construction fields.

The complete form of APAC LVL planks is laminated veneer lumber. Thin woods are specially engineered and assembled with adhesive to form LVL scaffolding planks.

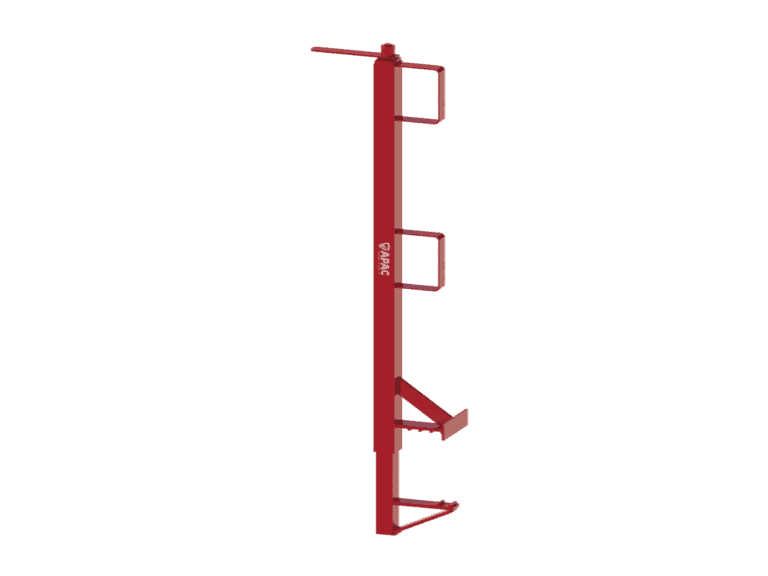

various lvl scaffold plank for you

APAC lvl scaffold plank

- Material: Poplar; Radiata Pine; Eucaplytus; etc.

- Size: 38x225x3900mm or as your need.

- Standard: OSHA

lvl scaffold plank with painting

- Width: 225/230mm

- Thickness: 38/40/42mm

- Length: 1-6M

- Any color is available.

lvl scaffold plank with steel flat

- Width: 225mm, 230mm, 235mm etc.

- Thickness: 38mm, 42mm, etc.

- Length: 2m, 3.9m, 4m, 6m, etc

Best LVL Scaffold Planks For Your Project

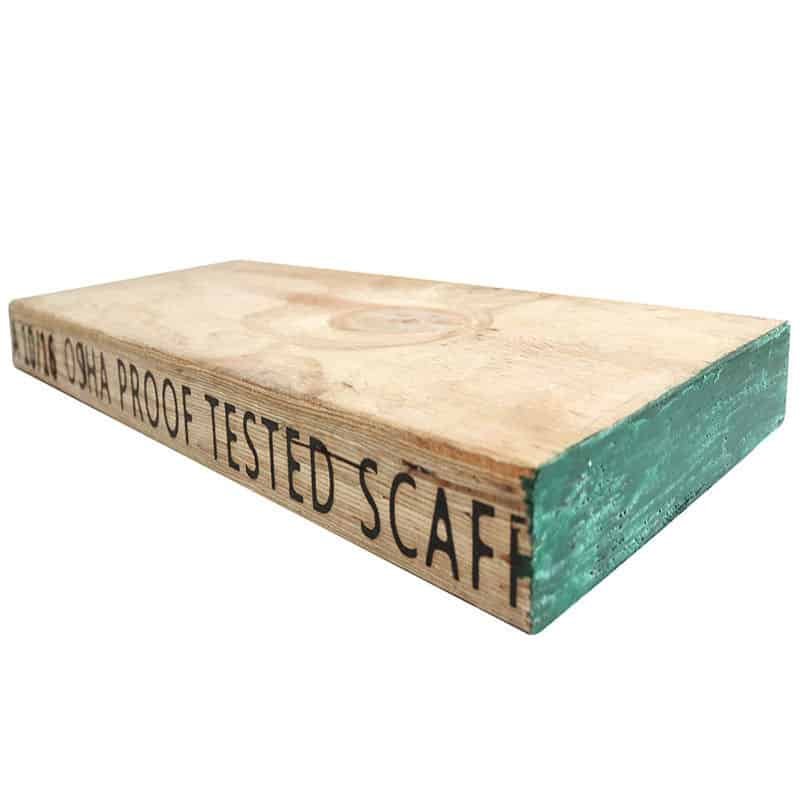

Our LVL Scaffold Planks are manufactured using “A” grade WBP Phenolic Glue. The planks have been tested and boiled in hot water at 100 degrees for 72 hours without any delamination.

To ensure quality, APAC LVL Scaffold Planks are produced under strict quality control and product certification. The wood we use is legally imported from New Zealand.

APAC’s LVL Scaffold Plank at the time of dispatch from our manufacturing site has a moisture content of between 10%-14%. The density of our planks is about 560-660 KGS/CBM. APAC LVL Scaffold Planks can only be used as scaffold planks, i.e. to support personnel, equipment, and materials on scaffolds constructed and loaded in accordance with AS1576 and AS1577.

Due to its composite nature, LVL Scaffold Planks are much less likely to warp, twist, bend or shrink than conventional solid timber, so a longer service life can save you cost.

More Description of LVL Scaffold Planks

Our LVL scaffolding planks are made of high-quality softwood that comes with the highest strength-to-weight ratio. APAC LVL scaffolding planks can retain their size and shapes at different seasons and adjust the humidity. As a result, site workers and site managers don’t need to worry about the expansion of scaffolding planks.

Properties of APAC’s LVL Scaffold Planks:

- Enhanced durability and safety.

- Unparalleled structural rigidity, stability, and strength

- proven to last at least twice as long as its solid wood equivalent

- 10% lighter than, for example, solid wood

- requires no ongoing maintenance or remedial repairs

- excellent electrical insulation properties

- excellent corrosion and chemical resistance

- Multiple color options for end seal

- Custom Lengths and Sizes

The LVL Scaffold Planks we supply to Australia and New Zealand are typically 38mm or 42mm thick, 225mm or 230mm wide, and come in lengths from 1.0m, 2.0m, 3.0m, 4.0m to 6.0m. Custom size is available upon request.

Our LVL Scaffold Planks are lightweight, compared to steel scaffold planks, they can reduce labor on site. And the Planks also meet the safe working loading requirements of AS/NZS 1577.

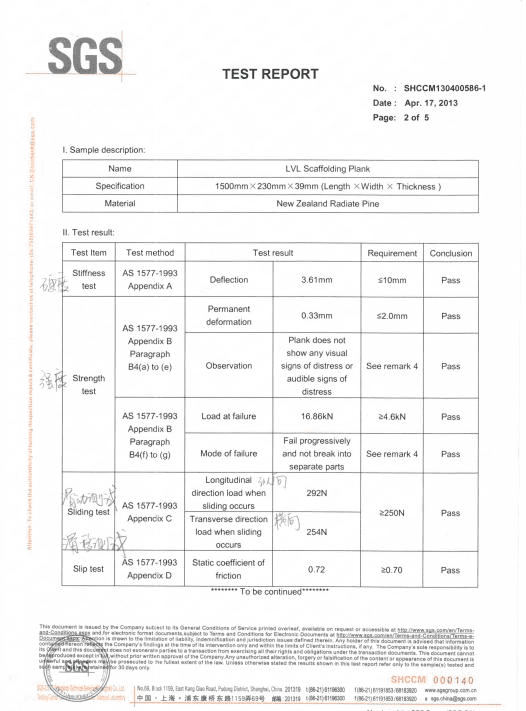

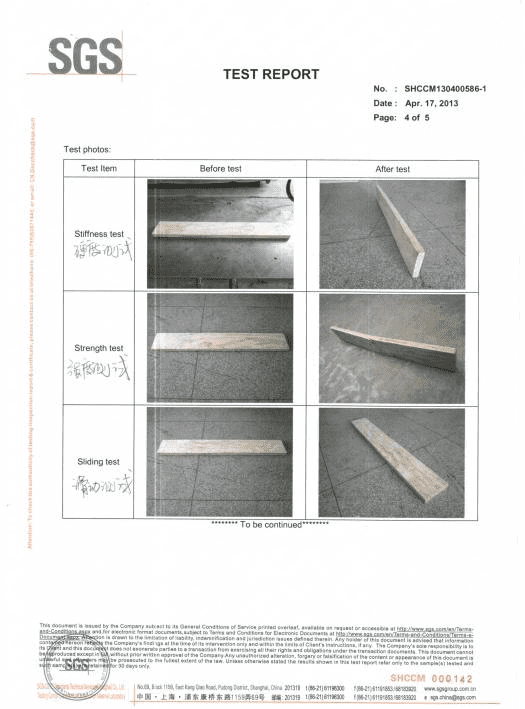

APAC’s LVL Scaffold Planks are individually tested for safety and performance verification, just share with you some testing results we did in SGS according to the standard AS/NZS 1577.

On dispatch, LVL Scaffold Planks are packed with.

Inner packaging – pallets are wrapped in 0.20 mm plastic bags.

Outer packaging – pallets covered by plywood or cardboard boxes and strong steel straps.

LVL Scaffold Planks can be used in place of metal scaffold boards or solid timber boards.

They are affordable and robust, especially in corrosive environments. Wax emulsion end seals reduce moisture ingress.

applications

LVL scaffolding planks are durable, have an extremely long life, and are lightweight and easy to handle. Pine LVL Scaffolding Planks are used in construction, formwork systems, bridgework, oilfield work, and more.

Some of the common applications of LVL scaffolding planks are:

- Providing support to construction materials.

- Creating working platforms in the construction site.

- Wood wall structure.

- Timber frame.

- Wood roofing.

- Low-cost wood flooring.

- Door and window manufacturing.

LVL Scaffold Planks | The Ultimate FAQ Guide

APAC is a leading LVL scaffolding planks supplier in China. This guide will help to understand the properties, sizes, and other features you should know before buying a scaffold board for your project.

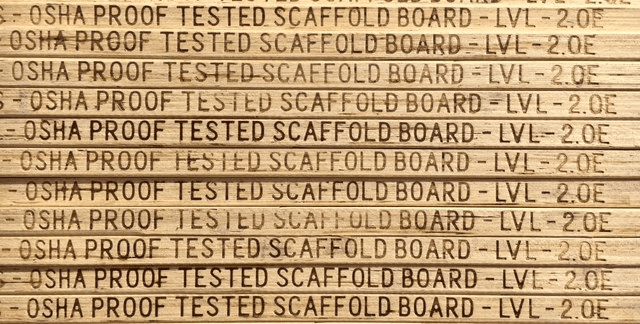

1.What is the OSHA Compliance For LVL Scaffolding Planks?

OSHA is a federal agency whose primary job is to ensure the safety of workers and offers long-term solutions for conventional workplace hazards. In 2013, OSHA listed scaffolding as the third most violated item in the workplace.

The organization stated that 45,00 workers get injured, which could be prevented with good quality scaffolding.

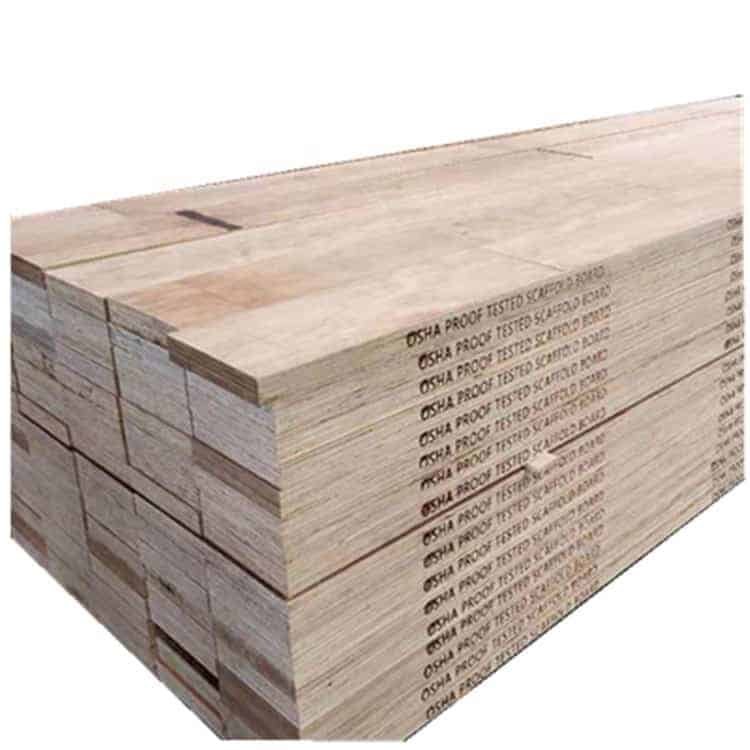

Figure 3 – LVL scaffolding planks must meet OSHA standards

Therefore OSHA released an extended regulations to ensure the scaffolding was well-built and sturdy. Here is the outline of OSHA, which should be applied to LVL scaffolding planks.

- Scaffold plank manufacturers must use scaffold-grade lumber.

- Manufacturers should monitor, assess and improve the wood condition.

- Scaffold planking MUST NOT deflect more than one-sixteenth of its span between supports.

- The deflection of scaffolding planks can not exceed 1/60th of its span supports.

Buying LVL scaffolding plans following the OSHA standard is a good idea, but it doesn’t always provide the best support for the workers. So, you have to select LVL scaffold boards according to the material and workers working on the site.

At APAC, we deliver immense effort to exceed the quality of LVL scaffolding planks beyond OSHA regulations. We ensure top quality by performing several tests in the manufacturing process. With our scaffolding board, you can be 100% sure that your workplace is 100% secure for the workers and free of hazards.

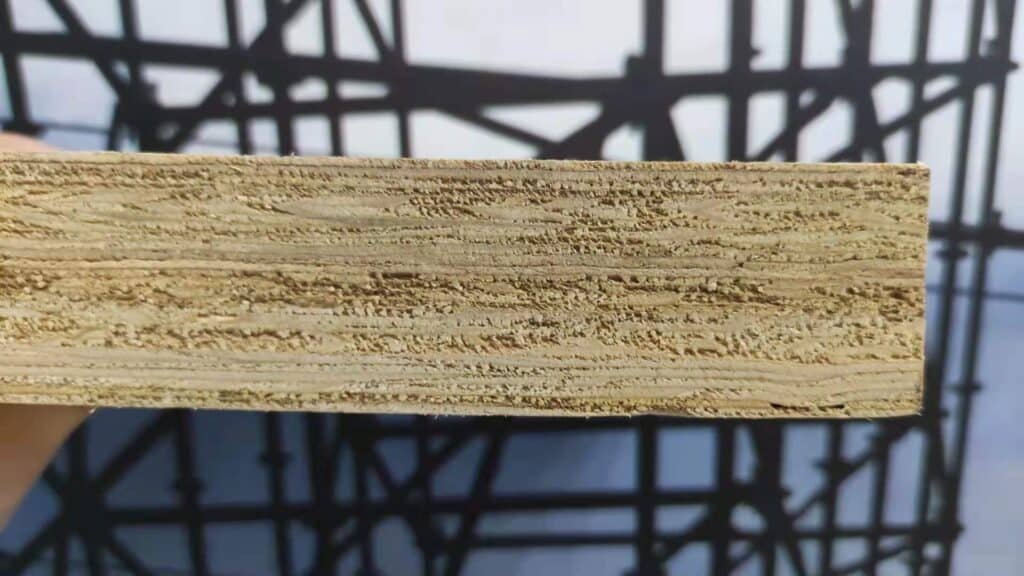

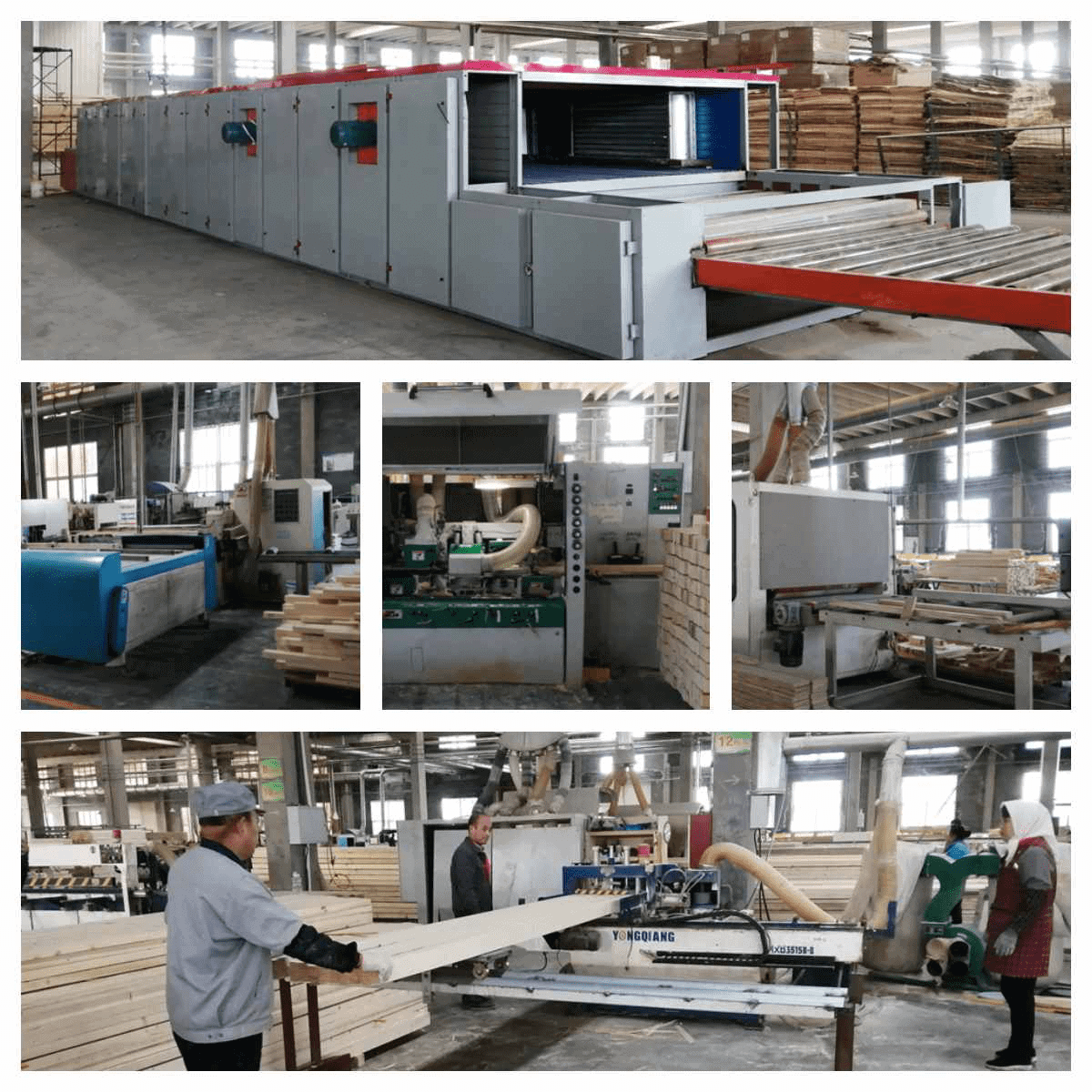

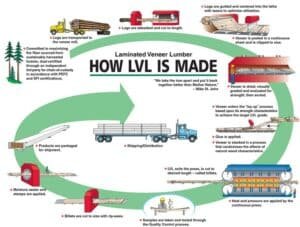

2. How LVL (Laminated Veneer Lumber) scaffold planks are made?

The whole production procedue is as below picture.

1.Committed to maximizing the fiber sourced from sustainably harvested forests.

2. Logs are transported to the veneer mill.

3. Logs are debarked and cut to length.

4. Logs are guided and centered into the lathe with lasers to optimize utilization. Veneer is peeled in a continuous sheet and is clipped to size.

5. Veneer is dried, visually graded and evaluated for strength; then sorted

6. Veneer enters the”lay-up”process based upon its strength characteristics to achieve the target LVL grade.

7. Glue is applied. Veneer is stacked in a process that randomizes the effects of natural wood characteristics.

8. LVL exits the press.is cut to desired length-called billets.

9. Heat and pressure are applied by the continuous press.

10.Samples are taken and tested through the Quality Control process.

11. Billets are cut to size with rip-saws.

12. Moisture sealer and stamps are applied.

13. Products are packaged for shipment.

14. Shipping / distribution.

3.How Much Weight Can A LVL Scaffold Plank Hold?

How much weight an LVL scaffold plank can hold depends on the amount of space between supports. For example, if you are using a 2X10 plank with a maximum of 10 ft span. In this case, the allowed load will be 25 pounds per square foot. Important to note that the load should be between the supports.

4.What Is The Standard Size Of LVL Scaffold Board?

It is a common question that we hear from our clients frequently. Standard LVL scaffold boards are 2 inches thick (1.5 to be exact), 10 inches wide (9.25 to be exact). The only thing that varies is the length.

You can know how to setup LVL scaffolding planks from the below video:

The standard length of LVL scaffolding planks is 13 ft. But there are other available sizes of scaffold board. For example, you can buy an 8,9,10,12,16 ft scaffold board. Moreover, you can customize the size to meet the requirements of your project.

5.What Wood Is Plywood Mostly Made From?

Most softwoods are used to make plywood. Some of the tops used to make plywoods are pine, cedar, spruce, and redwood. Douglas fir is the most common wood used for plywood and LVL scaffolding planks.

recent post

DIFFERENT TYPES OF GLUE USED TO MAKE PLYWOOD SHEETS AND OTHER WOOD PRODUCTS

The three main types of glue are urea-formaldehyde glue, melamine glue, and phenolic glue. You must consider which glue for your wood product.

LVL Scaffold Planks are stronger, straighter, and more uniform, and the waterproof paint seals the ends to reduce water ingress. This prevents the planks from becoming moldy and deteriorating.

LVL Scaffold Planks supplied by APAC are fumigation free and we will provide you with a Fumigation Certificate to help you clear customs easily without any resistance when importing.

If you have more questions, just call for our expert today!