PVC Tarpaulin

- 100% waterproof with optional non-slip surface treatment

- Roll widths up to 3.20 m to reduce seams and improve finished quality

- Heat-sealable seams for tougher joining and better water resistance

- UV-protected to withstand frequent sunlight exposure and weather cycles

- Built for long-term outdoor use—resists deterioration from rain and liquids

what is PVC Tarpaulin

PVC tarpaulins are made from high-strength polyester high-strength polyester canvas fabric coated with polyvinyl chloride (PVC) paste resin and a variety of chemical additives such as DOP, anti-aging and anti-static.

Colorful PVC Tarpaulin Can be choose

APAC offers a full range of color PVC tarpaulin options to help you standardize site management, brand visibility, and application zoning—without sacrificing performance.

RED PVC Tarpaulin

A high-visibility choice for warning zones, temporary covers, and high-traffic site areas. Red is often used when you want fast identification on busy construction sites while still keeping full waterproof protection.

White PVC Tarpaulin

Best for a clean, professional appearance and situations where you want brighter coverage under the tarp. White is commonly used for temporary enclosures, equipment covers, and applications where aesthetics and light reflection are helpful.

Yellow PVC Tarpaulin

Popular for safety-focused site coverage where visibility matters in low light or rainy conditions. Yellow tarpaulin helps crews spot protected areas and covered materials quickly, improving daily handling efficiency.

Purple Blue PVC Tarpaulin

A more premium, low-stain-visibility choice for heavy-duty and repeated-use applications. Purple can look cleaner over time on demanding sites, making it suitable for frequent handling, transport, and long-duration outdoor exposure.

Green PVC Tarpaulin

Often chosen for outdoor storage and long-term site protection, especially where a lower-contrast, environment-friendly look is preferred. Green is a practical option for yards, material storage zones, and perimeter cover use.

Blue PVC Tarpaulin

A widely used “all-purpose” option for construction and logistics covers. Blue provides a balanced, familiar look for general protection needs while remaining easy to match with standard packaging and site routines.

More Details About APAC PVC Tarpaulin

We are PVC waterproof tarpaulin supplier, the company has advanced production equipment, perfect scientific quality management system, provide various specifications of finished PVC tarpaulin, products are exported to all over the world. APAC always adheres to environmental standards and the materials we use are guaranteed to be free of tin organics, nonylphenols, and phthalates.

Different projects need different hand-feel, strength, and surface behavior. APAC offers wide spec ranges and additive options so buyers can balance cost, durability, and performance.

Width range: 40–260 inches

Thickness range: 0.2–5.0 mm

Softness range: 18–78 PHR

Additives available: anti-fungal, anti-aging, anti-static (and other performance packages on request)

Strong, site-ready build: oil-resistant, tough, tear & abrasion resistant, with optional rust-proof rings/loops for fast securing

Why Choose APAC PVC Tarpaulin

APAC PVC tarpaulin is engineered for long outdoor cycles and heavy site handling—where leaks, seam failures, and UV aging quickly turn into rework and replacement costs. You get reliable waterproof protection, cleaner fabrication with fewer seams, and spec flexibility (size, thickness, softness, additives) to match real applications.

Waterproof & Outdoor-Ready Performance

Built for year-round exposure, APAC PVC tarpaulin is designed to stay stable under rain, liquids, and frequent sunlight—without turning into a maintenance problem.

100% waterproof protection for outdoor covers and site use

Optional non-slip surface treatment for safer handling and use on wet jobsites

UV-protected to reduce degradation from repeated sun exposure

Fewer Seams, Stronger Seams

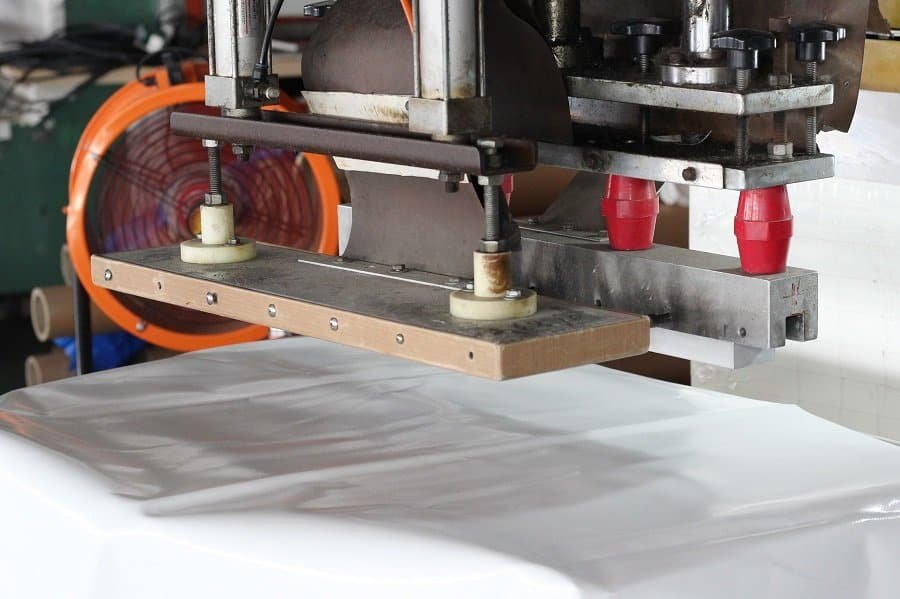

Seams are where most cover failures start. Wider rolls reduce seam count, and heat-welded seams create tougher, more watertight joins for finished products.

Roll width up to 3.20 m to reduce seams and improve finished quality

Heat-sealed / heat-weldable seams for stronger, more waterproof joints

Cleaner processing for large covers (less stitching, less leak risk)

Better consistency when fabricating truck covers, site covers, and industrial curtains

Factory Strength Behind Every Roll

APAC produces PVC tarpaulin in-house with controlled processes and export-focused QC, so bulk orders stay consistent with approved samples. We also follow environmental compliance requirements for overseas markets.

Advanced production equipment for stable coating uniformity and surface finish

Quality management system covering in-process checks + final inspection

Scalable supply for global export and repeat orders

Trusted by contractors worldwide

Application of PVC Tarpaulin

Our PVC tarpaulins are widely used across industries. Typical applications include:

Transport — truck tarpaulins, truck covers, truck side curtains/sidewalls

Construction & Agriculture — site tarps, construction covers, farm tarpaulins, commercial sewing products

Recreation & Entertainment — tents and awnings, inflatables, pool & spa covers, boat covers, float covers, ATV cab covers

Sports & Athletics — gym/exercise mats, gymnastics protection, wall mats, field covers

Loading Docks & Industrial Doors — high-speed roll-up doors, vinyl doors, dock seals/shelters, industrial curtains

Food Service & Hospitality — rack covers, equipment covers, patio enclosures

PVC Tarpaulin | The Ultimate FAQ Guide

1.What Is PVC Tarpaulin?

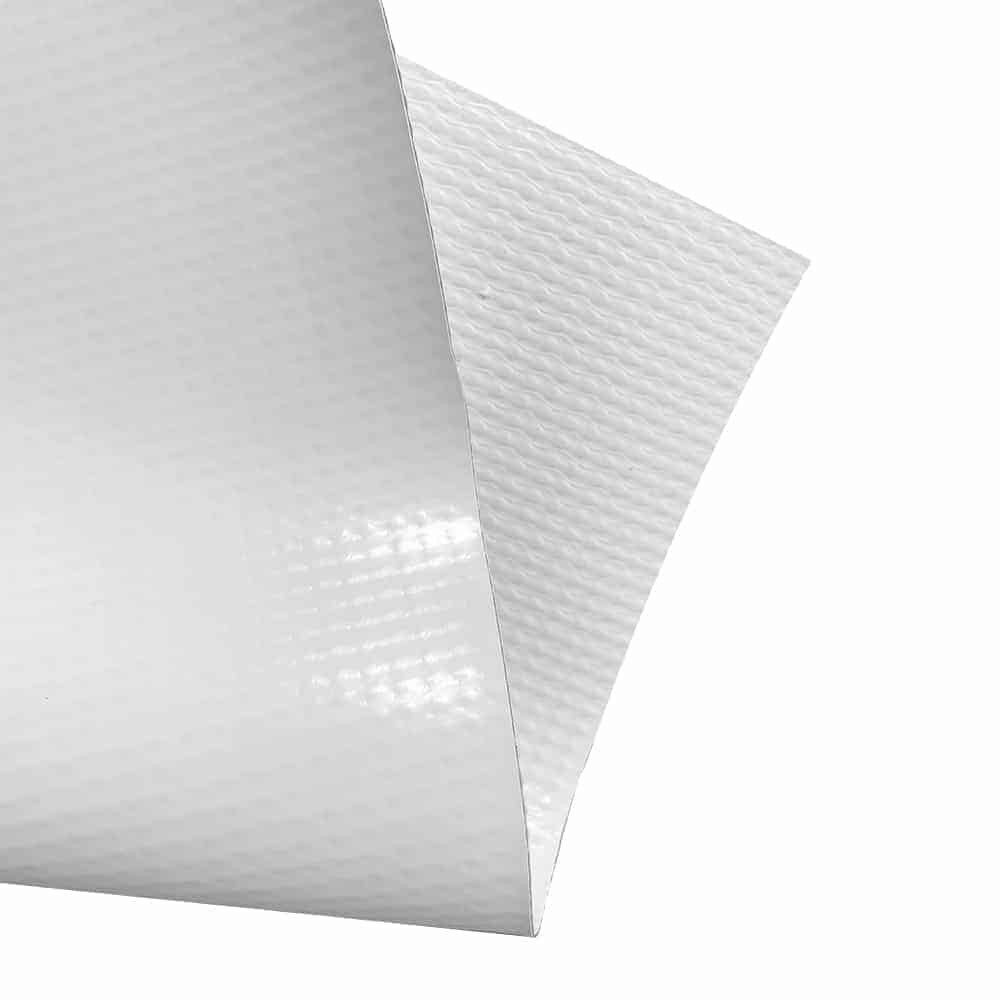

The PVC tarpaulin is a heavy-duty sheet that you can use to make a protective cover or temporary shelter for roofing, storage space coverings, etc. Most PVC tarpaulins are made from PVC-coated polyester scrim. The PVC or polyvinyl chloride is a dense plastic material with waterproof properties.

It protects the polyester fiber from moisture, which results in a highly durable material that you can use for a very long time. Due to its flexibility, excellent weatherproofing capabilities, and durability features, PVC tarpaulins are commonly used as roofing material with modular and non-modular temporary keder roof systems.

Figure 1 – PVC Tarpaulin

2.What Is The Difference Between PVC Tarpaulin And PE Tarpaulin?

PVC and PE are common materials used in the manufacturing of tarps. There are some differences between them, for why the quality and scope of application also vary. The expected differences are:

- Composition: The PVC tarpaulin is made from PVC and polyester. The polyester sheet is coated with polyvinyl chloride, a high-density plastic material. It has waterproof properties to protect the polyester sheet from moisture.

On the other hand, PE tarpaulin is made from PE or polyethylene. The center of the PE tarpaulin is made from woven PE strands, and the sides are laminated with PE sheet materials. - Strength:PVC tarpaulins are made from high-strength polyester and PVC. So, they are stronger than PE tarpaulins.

- Portability:PVC tarpaulins are heavy-duty sheets. They are heavier. Comparatively, PE tarpaulins are lightweight. You can also fold them for carrying or storage. So, PE tarpaulins are more portable than PVC tarpaulins.

- Weather protection:Both the PVC and PE tarpaulins are waterproof materials. But the waterproofing qualities of the PE tarpaulin are low. Another disadvantage is against bad weather. You might experience noise disturbances in high windy areas due to its less sturdy design and material properties.

Comparatively, the PVC tarpaulin has better waterproofing features. They are highly resistant to rough environments like heavy rain, wind, and UV rays.

Figure 2 – PE Tarpaulin

- Protection against wear:The PVC tarpaulins are designed for extended usage. They can withstand more abuse against wear compared to PE tarpaulins. So, you can use them for a longer time.

- Application scopes:PE tarpaulins are excellent for applications where you need temporary measures for a single or short period. But due to the heavy-duty performance of PVC tarpaulins, they are used in temporary roofing for transportation as truck cover, truck curtain side. They are also a reliable option if you want to protect expensive equipment and machinery.

3.Are The PVC Tarpaulin Fire Retardant?

One of the best features of PVC tarpaulins is their safety features. Manufacturers treat them with special chemicals which make them flame-retardant material. The PVC tarpaulin conforms to flame retardant standard with EN 13501-1, class B S1, D0.

If a fire is accidentally caught in the area where you have installed PVC tarpaulins, you don’t have to worry about the tarpaulins igniting more fire. In contact with fire, PVC tarpaulins do not burn like a normal material. It burns very slowly. They also sometimes extinguish automatically. So, you increase the safety feature in your installation area.

4.What Are The Benefits Of PVC Tarpaulin?

Some of the common benefits of PVC tarpaulins are:

- PVC tarpaulins are made from strong, heavy-duty materials.

- They are easy to use.

- PVC tarpaulins are lightweight. So, you can easily carry them.

- You can use them for temporary usage and reuse them for different purposes.

- PVC tarpaulins are very cheap. So, they are an affordable choice.

- Low maintenance is required for PVC tarpaulins.

- PVC tarpaulins are flexible, and you can adapt them for many applications.

- You can easily roll or fold the PVC tarpaulins. So, they are quick storage.

5.What Things Should You Consider When Choosing PVC Tarpaulin?

Things to consider when buying PVC tarpaulins:

- Analyze your target scopes and specify your requirements.

- Choose the thickness you require.

- Consider the density of the material.

- Tarpaulins are available in different colors. Pick the color choice.

Figure 4 – PVC Tarpaulins Are Available In Different Colors

- Consider the durability requirements like single or double sewn feature, heat-welded feature, etc.

- Review the weather-resistance capabilities.

6.What surface treatments are available (PVDF / acrylic / titanium dioxide)?

Surface treatments improve performance and surface behavior.

Anti-soiling / easier cleaning (better wettability)

Better aging & corrosion resistance (protective surface layer)

Higher wear resistance (surface hardness and abrasion resistance)

7.What is the typical temperature resistance range?

PVC tarpaulin can be engineered for harsh weather use.

Typical range: -30°C to +70°C

Suitable for hot, high-UV regions when UV stabilizers are specified