APAC’s Ringlock scaffolding is one of the world most widely used scaffold systems. APAC’s ringlock scaffolding is a fully galvanized multi‐purpose steel scaffold system, it is suitable for providing general access and supporting vertical loads. The comprehensive range of APAC Ringlock scaffolding main components allows it to be used to create a huge range of access and support structures, staircase towers, circular scaffold, loading towers and mobile towers.

Durability

There are no loose components on the Ringlock scaffold system that can be lost or require maintenance.

Versatility

APAC scaffolding can be erected for straight, curved, or circular configuration for both access and support, and also for independent and mobile towers.

Multi-Functional

With the universal joint and fully interchangeable components, the APAC ring system can be used in most construction projects (Civil & Building) for both falsework and access. Also concert staging and the Aviation industry.

Tensile Strength

Both APAC vertical standard and horizontal ledger are manufactured from 1.9" outside diameter by gauge 10 high strength steel tubing with a minimum yield strength of 50,000 lbs/in² and a min. ultimate tensile strength of 75,000 lbs/in².

APAC Ringlock scaffolding is used for all forms of access and support structures in the building, aviation, events, construction industries, ship building, industrial maintenance, offshore construction.

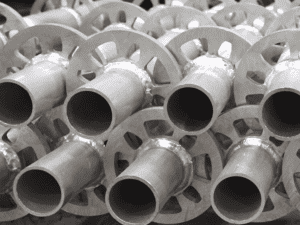

Ringlock scaffolding standard is the vertical member of Ringlock scaffolding while providing vertical support for scaffolding

Ringlock scaffolding Ledger are the horizontal members of ringlock scaffolding, they provide horizontal support for loads and planks.

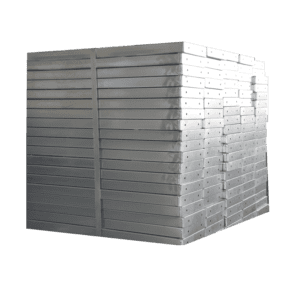

Aluminium Stairs towers are constructed utilizing scaffolding frames,cross braces, guardrail brace, planks, stairs.

Ringlock Scaffold diagonal Brace is for the lateral bracing Ringlock scaffolding. It use as hand guard rails in stair systems as well.

A scaffold adjustable base jack adapts to uneven construction surfaces and ensures the entire scaffolding system remains level.

The scaffold start collar comes with a single rosette installed on the base jack, and acts as a base.

APAC was found in the year 2014, we have been an expert of ringlock scaffolding company for over 7 years. APAC is a China-based ringlock scaffolding supplier, we specialize in the Manufacturing & Sale of ringlock scaffolding. APAC always strives to set and maintain the very highest of standards in safety and the supply of the highest quality ringlock scaffolding components.

APAC’s aim is to ensure you get your project built on time, on the budget without risk. Always feel confident and secure that your business is our number one priority.

APAC’s mission is to work closely with our clients, architect, or designer to get a clear understanding of their needs and intended outcome. In dealing with APAC, you have the benefit of dealing with an experienced, professional, and motivated team who’s committed to attention to detail, working to a budget, a timeline, and keeping a high standard.

APAC is committed to placing clients’ interests first with uncompromised integrity, transparent cost reporting, and exceptional service. When completing a project, whether a high‐rise tower or a small interior renovation, APAC provides the finest quality in construction results with the most cost-effective use of every construction.

The rigid node joint of APAC Ringlock scaffolding reduces the need for bracing, it gives a clear uninterrupted working platform, and the platform can be formed using traditional scaffold boards or batten.

The Ringlock scaffolding can be designed, engineered, and manufactured to fit any type of aircraft and multiple types of aircrafts as well.

APAC provides high quality, yet relatively low cost aircraft docking systems. This will result in a safe and efficient work structure that will be cost effective.

All APAC components are hot‐dipped galvanized finish with minimum zinc coating of 60 microns and manufactured to international standard.

Ringlock scaffoldings are highly adaptable for variable scaffolding solutions. You can set this up very easily and within a very short time period.

The different advantages make ringlock scaffolding a popular and ideal choice in the construction industry.

Choosing the ringlock system for your scaffolding solutions will benefit you in so many aspects.

Read through this FAQ guide to know more about ringlock scaffolding.

Ringlock scaffolding is a system where you use a socket-type disk buckling method to connect the framework members. Due to the shape of the buckling system, it’s named ringlock scaffolding.

You can use this for all kinds of professional scaffolding solutions. Use the ringlock scaffolding members to set up a temporary working platform. This robust platform will help you to elevate and support your workers and materials at different stages of construction.

Figure 1 – Ringlock Scaffolding System

There are so many ringlock scaffolding components that you can use to achieve high versatile setup opportunities. These are:

Figure 2 – Vertical Standard For Ringlock Scaffolding

Figure 3 – Castor Wheel

Figure 3 – Castor Wheel

You don’t need all these components for a standard ringlock scaffolding setup. Based on your application and how you want to set it up, you need more components from this list to assemble the ideal ringlock scaffolding system.

Figure 4 – You Can Use Ringlock Scaffolding System For Many Applications With Versatile Features

The versatile features of ringlock scaffolding are:

You can use the ringlock scaffolding system for different kinds of applications. The most common ones are:

Figure 5 – Ringlock Members Configured For Formwork Support System

You need ringlock scaffolding ties to ensure lateral stability. These are crucial members when you want to assemble a ringlock scaffolding system.

With stability in lateral directions, you can keep your working platform standing, so it doesn’t blow over, buckle, or fall over. The ringlock scaffolding ties will keep your setup safe against live load and wind load.

You need to use the ringlock scaffolding ties in a planned manner. You have to design and locate the positions where you need to set the ties. Place them at regular intervals following the design to achieve a balanced and sufficient lateral stability.

You can very easily set up the ringlock scaffolding system. Just follow these simple steps:

Figure 6 – Ringlock Connection Procedure

You have to use castor wheels to make your ringlock scaffolding towers portable. With the portable feature, you can easily reposition the tower by rolling them over a flat surface.

The ringlock scaffolding members are lightweight, and the connections are secured. So, you can easily reposition them to a new location without dismantling the previous connections.

To add this feature, you have to remove the adjustable base jack and install the castor wheels in their position.

But always make sure that there are no workers or existing material on the ringlock scaffolding tower when you are repositioning them.

The adjustable base jacks assist you in setting up the ringlock scaffolding system on an uneven surface.

Just make sure to secure the base jacks on a firm and hard surface. Then connect the first stage ledgers with the spigots. Observe whether the ledgers are tilting due to uneven surfaces.

If the ledgers are tilting, use an alignment fixing bubble scale. Rotate the adjustment threads of the base jack to correct the tilting until they are perfectly parallel to the alignment scale.

APAC has a professional technical service team, we can design and calculate the amount of scaffolding according to your needs. Don’t worry, it’s free!

We can be contacted directly via email or phone. Many of APAC’s sales have engineering backgrounds and are fluent in English and can address your questions more quickly and directly.