Introduction

According to a famous quote, “It is only when you go wrong, the technology will remind you how powerful it is”. This famous quote also sheds light on the latest scaffolding product: Ringlock scaffolding. Nowadays, Ringlock scaffolding is the most popular technology used for safety purposes.

A large number of Ringlock scaffolding has been supplied and manufactured by different high-quality brands to promote its use. A scaffold ringlock system is being the most used safety item in your key projects and key job site. There are a lot of factors contributing to the popularity of Ringlock scaffolding such as material, capacity, size, weight, structure, etc. This blog will guide you to know about all these factors.

Raw Material Of Ringlock Scaffolding

The raw material of any product has an important role in the capacity, structure, quality, and weight. The same is the case with your latest Ring lock scaffolding for the construction site. Having a high-quality raw material can ensure the high-quality of your Ringlock scaffolding systems in terms of structure, capacity, weight, and a longer lifespan.

Another key point to note here is that only a good supplier and manufacturer can give you high-quality Ringlock scaffolding systems. It is because they prioritize the safety as well as the satisfaction of their customers. For them, the brand reputation matters a lot. Therefore, they will not make use of material that costs the life of their customers.

In the case of scaffolding Ringlock systems, there is a wide range of material used depending upon the supplier and manufacturer and availability of resources. However, the most commonly used high-quality materials are Q235(Equal to S235) and Q345(Equal to S355). Only high-quality scaffolding manufacture understands the importance of using these two materials in their Ringlock scaffolding systems.

Since no good suppliers will want to put the reputation of their company at risk, they make use of Q235(Equal to S235JR) and Q345(Equal to S355JR) steel grades. These are two categories of high-quality steel that have a higher capacity to help you get the best Ringlock scaffolding systems. We recommend you use the Q345(Equal to S355) for Ringlock Scaffolding Standards and Q235(Equal to S235) for other Ringlock Scaffolding components.

What Are Q235 ( S235) and Q345 ( S355)?

- Q235(Equal to S235) is actually a code used for a particular type of carbon structural steel. This kind of steel is mostly used throughout China for Ringlock scaffolding systems manufacturers. Most of the high-quality suppliers prefer Q235 to supply high-quality Ringlock scaffolding parts. Q235(Equal to S235) steel is also referred to as Q235A, Q235B(Equal to S235JR), Q235C(Equal to S235J0), Q235D(Equal to S235J2), and Q235E (Equal to S235K2).

The best property of Q235 (S235) material is that one can use it without processing it through special heat treatment. The reason behind this property is its mild nature. Q235 (S235) material Ringlock scaffolding systems have better weldability and plasticity properties.

It has amazingly adequate and comprehensive performance due to moderate carbon content. Q235(S235) material is composed according to the PRC standards. Q235 material also acts as a substitute for A36 material due to its low maintenance properties.

- Q345(Equal to S355) is another most commonly used manufacturing material for Ringlock scaffolding systems across China. Q345(Equal to S355) steel is also referred to as Q345A, Q345B(Equal to S355JR), Q345C(Equal to S355J0), Q345D(Equal to S355J2), and Q345E (Equal to S355K2). It is a low alloy steel material having most of its uses in construction industries. Due to its flexible properties, it is also used in a wide range of ships, bridges, and motor vehicle manufacturing.

Another most common name used for this material is GB/T 1591. The interesting point to note here is that Q in “Q345” denotes the yield point while “345” denotes the strength of its yield strength is minimum 345 Mpa. There is an indirect relationship between yield value and the thickness of Q345(S355) material.

The higher the thickness value, the lower will be the yield value of your Q345(S355) material. Q345(S355) material has an excellent performance in low temperatures with excellent plasticity and weldability.

- Price Difference

The price of both materials has a difference of only 3% to 8%.

Both of these materials have their own amazing properties. You can prefer one over the other based on your requirements since we can customize it for you. Q345(S355) is more preferable for general strength design since it can also save almost 15-20% steel as compared to Q235 (S235).

On the other hand, Q235(S235) steel is considered better for control design and stability purposes.

Why Ringlock Scaffolding Is Suitable For High And Complicated Projects?

Ringlock scaffolding systems are popular in the construction market due to a lot of reasons. When talking about high and complicated projects, only high-quality products with the best properties can make them successful. In the case of the Ringlock scaffolding application, there are thousands of reasons to explain its suitability for complicated projects.

However, some of the major reasons to prefer Ringlock scaffolding systems are explained here.

- Ringlock scaffolding design has a simple and easy-to-use structure to help you get better temporary support for crews and materials during construction.

- Due to the use of Q235(S235) and Q345(S355), Our Ringlock scaffolding systems have a high bearing capacity to make your projects successful. It has a convenient disassembly and construction.

- The Ringlock scaffolding systems have the ability to meet the support operations of large-span, overweight, and super-high structures. This is the reason why engineers also prefer it during the construction of highway bridges, large-scale factories, stadiums, and so many other complex projects on a large scale.

- The other factor to make use of Ringlock scaffolding systems in large projects is its higher safety component.

Conclusion

Ringlock scaffolding systems can help you achieve targeted outcomes out of your large-scale and complicated projects. This explains why it is popular in the market. For choosing a better Ringlock scaffolding manufacturer, we have summarized a few points in the conclusion. You can get an idea of choosing the best Ringlock systems after reading this section :

- When choosing the best Ringlock scaffolding system, you should make sure that the supplier is giving you the products with high-quality steel grade. The steel grade has a direct effect on the capacity as well as structure of your scaffolding Ringlock systems.

- Secondly, you should make sure that the supplier has treated its Ringlock scaffolding accessories surface with high-quality hot-dip galvanized. Actually, hot-dip galvanized can induce anti-corrosion properties to your Ringlock scaffolding systems making it last longer than the expected lifespan.

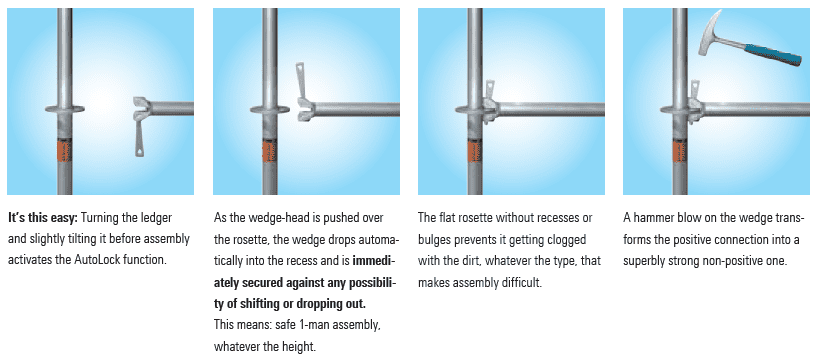

- Last but not least, you should make sure that the cast ledger head of your Ringlock scaffolding system is cast from a precision wax mold, not a sand mold.

One more thing to tell you here is that you should always prefer a high-quality supplier instead of cheap-priced and low-quality suppliers. No matter what the cost is, only high-quality products can help you complete your complex projects.