Scaffolding

- Trusted by contractors and developers globally, offering over 10 years of expertise in scaffolding systems.

- Cost-effective scaffolding solutions, providing excellent return on investment with reusable and modular components.

- End-to-end scaffolding support, from design and project management to installation guidance and quality inspection.

- Customizable scaffolding solutions tailored to your project’s specific needs, ensuring seamless site fit and safety.

what is scaffolding in construction

Scaffolding is a temporary structure used to support workers, tools, and materials during the construction, maintenance, or repair of buildings and other large structures. It provides a safe, elevated platform for workers to access hard-to-reach areas, ensuring stability and support throughout the project. Scaffolding is typically made from materials like steel, aluminum, or wood, and can be assembled and disassembled as needed.

Scaffolding Solutions——Meet All of Your Needs

APAC offers a comprehensive range of scaffolding solutions designed to meet the diverse needs of construction projects, from residential to industrial scale. Whether you need ringlock scaffolding, frame scaffolding, or modular systems, our products are engineered for strength, safety, and efficiency.

With years of experience in the industry, we provide not just high-quality scaffolding products, but also tailored solutions to suit your specific requirements. From design and planning to on-site installation, APAC delivers end-to-end scaffolding systems that are durable, cost-effective, and compliant with safety regulations.

Ringlock Scaffold

Ringlock scaffolding is a versatile, modular system that uses a ring-shaped connector to join vertical posts, horizontal braces, and other components.

Cuplock Scaffold

Cuplock scaffolding features a unique locking mechanism where cups are used to connect the vertical and horizontal components.

kwikstage Scaffold

Kwikstage scaffolding is a fast and efficient system with pre-engineered components designed for quick assembly and disassembly.

Frame Scaffold

Frame scaffolding is a traditional, pre-fabricated system consisting of vertical frames and horizontal cross braces. It’s quick to install and is often used for straightforward scaffolding solutions.

Tube and Clamp scaffold

Tube and clamp scaffolding uses steel tubes and clamps to create custom scaffolding configurations. It offers flexibility in design and can be easily adapted for complex structures.

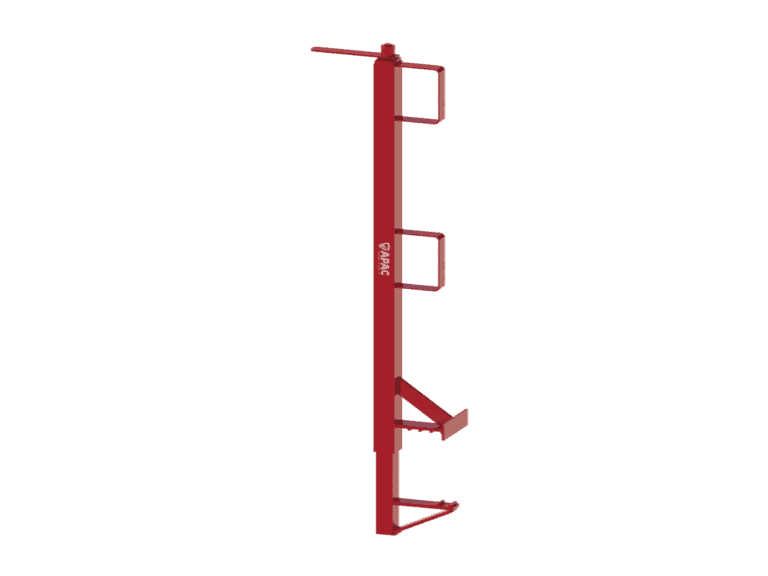

Scaffold Tower

APAC scaffold towers also called 3T Industrial Scaffold Tower, is manufactured from Alloy 6061 T6 or Alloy 6063 T6 materials. They strictly conform to European standard EN 1004 and Australia/New Zealand Standard AS/NZS 1576.

Scaffold Tag

Scaffold tags are used to indicate the safety status of scaffolding systems, ensuring workers can quickly identify whether a scaffold is safe to use.

scaffold plank

Scaffold planks are used to create work platforms in scaffolding systems. Made from wood or steel, they are designed to support the weight of workers and materials.

Brick Guard

Brick guards are safety barriers used in scaffolding systems to prevent debris or bricks from falling off the scaffolding and onto workers or pedestrians below.

Debris netting

Debris netting is a protective mesh that wraps around scaffolding to catch and contain falling materials, such as tools or debris, preventing them from causing injury or damage below.

Fire retardant containment mesh

Fire retardant containment mesh is designed to contain debris while also providing fire-resistant properties. It’s ideal for sites where fire safety is a concern.

Fire retardant PVC Mesh

Made from durable PVC material, it’s used in scaffolding applications where fire safety is crucial, providing extra protection against fire risks while maintaining visibility and airflow.

More about APAC Scaffolding

Why Choose APAC for Your Scaffolding Solutions

At APAC, we are dedicated to offering comprehensive scaffolding solutions that go beyond just providing high-quality products. As a leading scaffolding manufacturer in China, we provide end-to-end support throughout the entire project lifecycle—from design and product supply to installation guidance and project management. Our services include project information tracking, analysis, quotation, and ensuring smooth transportation with door-to-door service.

Full-Service, End-to-End Solutions

APAC is more than just a manufacturer—we are your scaffolding partner. We provide project management support, quality inspections, and technical guidance throughout your project, helping you manage everything from the initial concept to final installation.

- Complete project solutions from start to finish

- Guidance on product design, application, and development

- Expert support during installation and project management

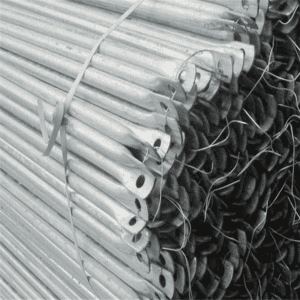

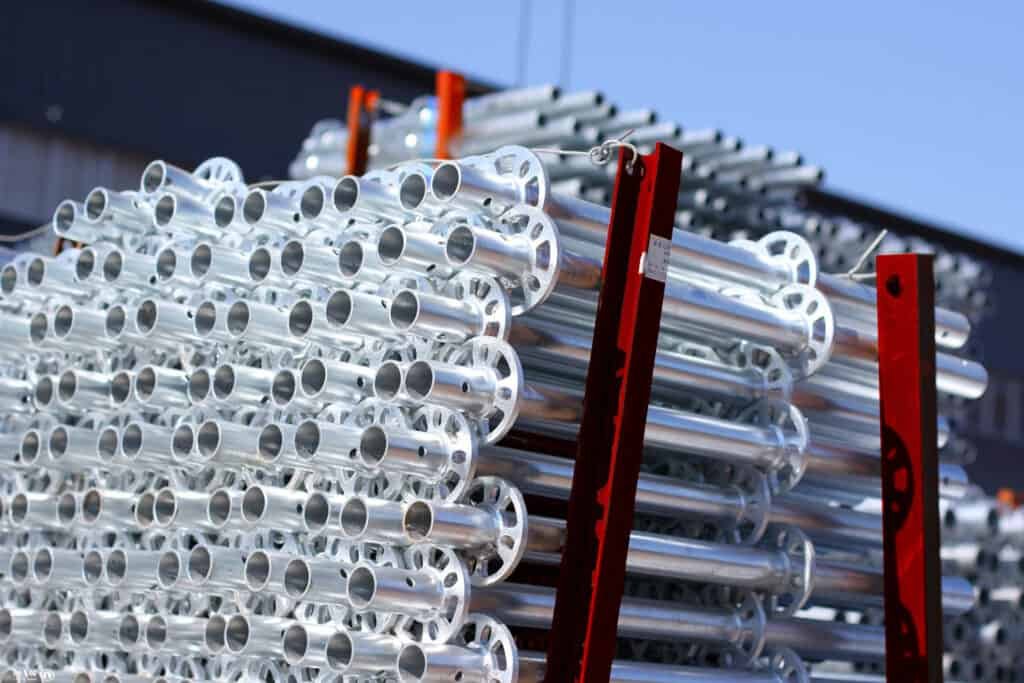

Proven Quality & Durability

Our scaffolding systems are crafted from high-strength steel, and all components are hot-dip galvanized for enhanced durability and corrosion resistance. APAC scaffolding can last 7-10 years, ensuring long-term reliability and cost-effectiveness for your projects.

- High-quality steel components for strength

- Galvanized finish for long-lasting protection

- Durability that ensures long-term use and reduces maintenance

Global Compliance & Flexibility

APAC products comply with internationally recognized standards such as EN 12810/12811, ANSI/SSFI SC100-5/05, and AS/NZS 1576. Additionally, our systems are designed for easy integration with Layher All-round scaffolding, providing flexibility and cost savings for your procurement process.

- Meets global standards for safety and quality

- Flexible compatibility with Layher systems for procurement efficiency

- Cost-effective solutions without compromising safety

Efficient & Cost-Saving Operations

APAC scaffolding systems are designed for easy installation, allowing you to reduce labor costs and shorten your construction timelines. Our systems are intuitive and require fewer resources to complete, ultimately saving you time and improving project efficiency.

- Quick and easy installation reduces labor costs

- Streamlined operations for faster project completion

- Reduced overall costs through operational efficiency

Trusted Partner for Global Projects

With years of experience in the industry, APAC has built a reputation for being a reliable and trusted partner for scaffolding needs worldwide. We provide personalized support to help you navigate market development, and ensure timely delivery—helping you complete projects on schedule and within budget.

- Comprehensive support for global projects

- Dedicated customer service for smooth execution

- Timely delivery for consistent project flow

Choosing APAC scaffolding solutions means choosing a partner that prioritizes your project’s success, offering high-quality products, expert support, and cost-saving solutions that ensure safe and efficient operations. Let us handle your scaffolding needs, so you can focus on what matters most—completing your project successfully.

Trusted by contractors worldwide

Applications of scaffolding

APAC scaffolding systems are versatile and adaptable, designed for a wide range of applications including internal access, roofing and weather protection, public access, offshore/onshore projects, bridging systems, petrochemical work, refurbishment, demolition, and civil engineering. Whether you need safe access, temporary protection, or solutions for complex structural tasks, APAC provides reliable, cost-effective scaffolding systems that meet the specific needs of your project while ensuring compliance, safety, and efficiency.

Scaffolding | The Ultimate FAQ Guide

1.What Is Scaffolding?

Scaffolding is a support structure that you can use to get a temporary form of access at a certain height. You can either build a scaffold with various components or assemble it using pre-fabricated components.

When you perform different kinds of construction works at an elevated height, you need a working platform that can support you with a suitable position from where you can conveniently perform your work. The scaffolding can hold multiple people with or without materials to provide you the flexibility at working from heights.

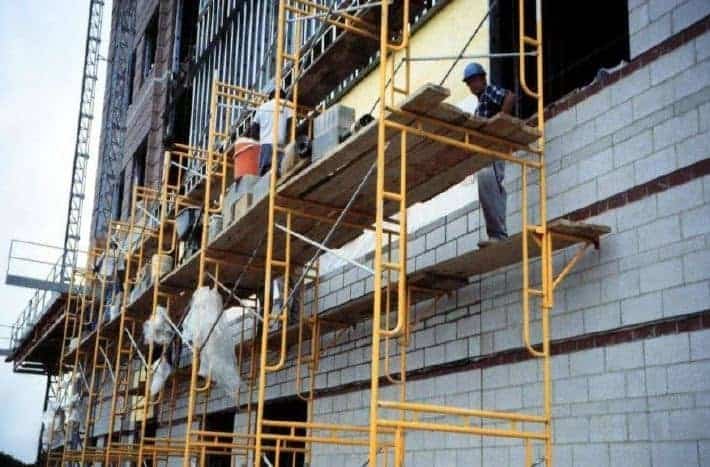

Figure 1 – Construction Work Performed On Scaffoldings

2.What Are The Practical Uses Of Scaffolding Applications?

There are so many practical usages where you can make use of scaffoldings for your practical purposes. They include:

- You can use different kinds of structural scaffoldings for construction works.

- You can use the scaffoldings in different kinds of exterior repair works where workers need to work from heights.

- For exterior painting works, you can use the scaffolding to work as a working platform where.

- You can use a scaffolding working platform with flexible height-changing features in different kinds of indoor applications like fitting appliances, repairing, etc.

- With multi-level scaffolding, your construction workers can perform tasks simultaneously at different levels for different types of construction.

- In structures with tight areas where you don’t have surrounding space to set up scaffoldings from the ground, you can suspend them from the top to access your level.

- It is sometimes troublesome to work on structures with complicated geometry. In those hard-to-reach positions, specialized cantilever scaffolding can be your ideal choice.

- You can use the scaffoldings for brick masonry works at elevated heights.

Figure 2 – Scaffoldings Used To Perform Brick Masonry Works

- To temporarily store materials at elevated heights, you can use the scaffoldings as a holding platform while you perform your work.

- Apart from construction or repair works, you can use scaffoldings for different photo shooting or video shooting applications, where the professionals need to secure a good view from heights.

- Set up different kinds of lighting and decorating appliances at various events or organizations.

Figure 3 – Scaffoldings Used To Get A Better View For Sports Media Entertainment

3.How Can Scaffold Towers Benefit You Over Permanent Scaffoldings?

You can either build your own permanent scaffolding using wood, metal, or other materials for your different working solutions. But the pre-fabricated scaffold towers can benefit you much more. Let’s explore:

- The pre-fabricated scaffold towers are highly adaptable with versatile connection angles and mechanisms. So, you can assemble them in any design you want.

- It’s quicker to set up the scaffold towers using the pre-fabricated components.

- The installation procedure follows simple connection mechanisms. So, you can easily assemble them.

- The components of the scaffold towers are designed from lightweight materials to give you the extra mobility feature.

- If you are looking to use the scaffoldings for a long time in extreme weather conditions, scaffold towers made from durable materials are a great option for you.

- Since you can dismantle and reassemble scaffold towers, it becomes a cost-effective investment over long-term usage.

- The scaffold towers are manufactured by companies following specific guidelines and conforming to legal standards. So, you can be reliable on their safety and legal compliance.

4.How Many Loads Can You Apply On The Scaffoldings?

Each scaffolding is capable of carrying different amounts of load. The load-carrying capability of the scaffoldings depends on the size and design components. To determine how much load you can apply on the scaffoldings, you have to see the specifications.

When you opt for scaffoldings, you can see that the manufacturer will specify detail on safe working load or SWL. The SWL per platform means the safe load that you can apply to each platform. The SWL per tower is applicable for multilevel scaffolds, and it means the safe load that you can apply on the whole tower.

5.What Materials Are Used To Manufacture Scaffoldings?

The typical scaffoldings are manufactured from steel, aluminium, bamboo, etc. Different materials offer different kinds of benefits when you use them for your practical purposes:

- Steel:Scaffold towers manufactured of steel components are extremely strong. So, stell scaffoldings can offer you a high load-bearing capacity. Moreover, the manufacturers now use galvanized steel to manufacture scaffoldings, which makes them highly resistant to corrosion. So, you don’t have to worry about their durability.

- Aluminum:Aluminum scaffold towers are growing extremely popular in the scaffolding market due to their low-weight properties. Despite their low weight, they are very strong materials. So, you can flexibly handle aluminium scaffolding components and easily transport them.

- Bamboo:The primary advantage of bamboo scaffolding is that they are readily available and lightweight. So, you can quickly secure your scaffolding connections. Overall, you can make a low-cost investment using bamboo scaffoldings.

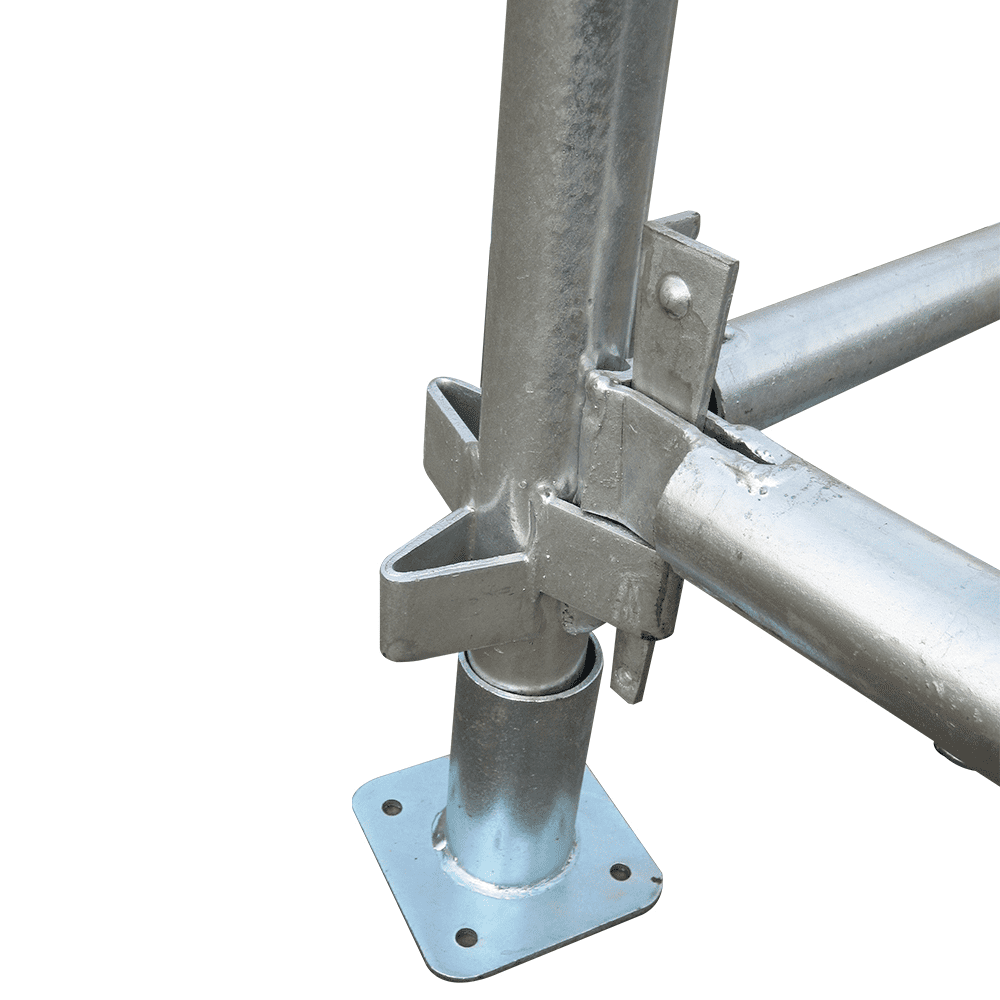

6.What Are The Components Of Scaffoldings?

The different components of typical scaffoldings are:

- Frame

- Bracing members

- Guardrail

- Platform system

- Toeboards at platforms

- Clamping/connection components

- Baseplate

- Castor wheel

7.What Are The Types Of Scaffoldings?

There are different kinds of scaffoldings like:

- Trestle scaffoldings– They have a support system with flexible ladders acting as tripods. So, they are better for indoor usage.

- Patented scaffoldings – Patented scaffoldings use brackets on which you can install the working platform.

- Ringlock scaffolding system– You can connect the members by ring lock mechanism, a very fast and secured form of connection.

Figure 4 – Ringlock Connection

Figure 4 – Ringlock Connection

- Cup lock scaffolding– You can connect the members by a mechanism termed a cup lock. This is also a very fast and secure form of connection.

- Kwikstage scaffolding– This is an extremely popular scaffolding system due to its very easy installation process. So, you can use them for small to large-scale operations.

- Pipe and coupler scaffolding– The platforms of these scaffoldings are supported by pipes and connected with coupling devices.

- Suspended scaffolding– Suspended scaffoldings are hanged from the rooftop to below to access the target height.

- Cantilever scaffolding– This kind of scaffolding is necessary when you cannot get access to your desired position in a complex structure with the traditional scaffoldings.

- Single or double platform scaffolding – When you need to add extra width to your working platform or support construction materials simultaneously, you can use a double platform instead of single platform scaffolding