An H20 beam is a timber I-beam used in concrete formwork as a primary or secondary beam to support slabs, walls, and columns during pouring.

It typically has:

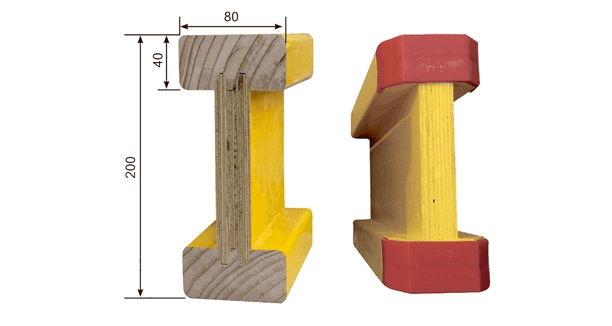

A 200 mm height (“H20” / “H200”)

Solid wood flanges (top and bottom chords)

A laminated plywood web (the middle core)

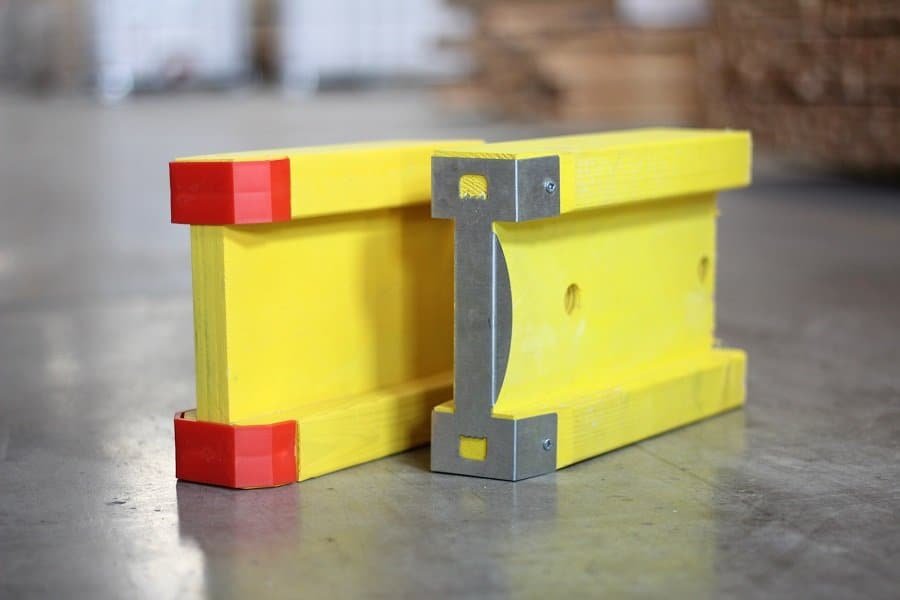

Often plastic or steel end caps to protect against impact and moisture

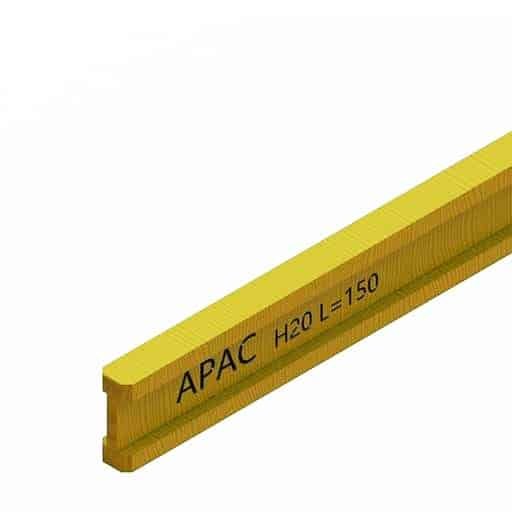

As a leading producer and supplier, APAC manufactures H20 timber beams in line with European Standard EN 13377 requirements, providing a clear technical benchmark for procurement and site teams. To match different jobsite conditions and handling intensity, we offer multiple configuration options for APAC H20 beams below.

Add your brand name and markings on the beam for easier site identification and rental asset control. OEM printing helps reduce mix-ups, improves traceability, and supports distributor branding.

Plastic end caps protect the beam ends from impact and moisture during handling and reuse. A good choice for regular jobsite turnover when you want longer service life at a practical cost.

Designed with an end joint solution to connect beams in line for specific formwork layouts. It helps extend effective length and supports flexible setup when continuous beam runs are required on site.

Steel end protectors offer stronger protection against heavy impacts, rough lifting, and frequent drops. Best for rental fleets or tough sites where beam ends take the most damage and wear.

APAC H20 beams are certified according to the European standard EN 13377, ensuring you can use the product without concern.

The H20 wooden beam end can also be fitted with plastic or steel caps to protect them against impact and moisture. The caps can protect the ends from hits.

Type of wood: New Zealand Radiate Pine, etc

Weight: 5.0 kg/m

Wood humidity: 12%±2%

Gluing: melamine resin-based glue, type EN 30, approved for fixing wooden structural components

External: made of selected solid fir and coupled with 80 x 40 mm section – milled and perfectly calibrated for an optimal assembly with core

H20 Beam Surface: treatment with water repellent yellow paint

H20 Beam Head: sprayed with waterproof paint, or fixed with plastic caps or steel sleeves

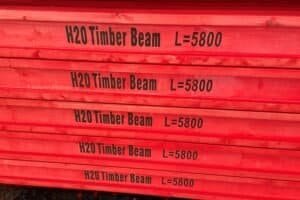

Standard length: 1.3 / 1.45 / 1.95 / 2.45 / 2.65 / 2.90 / 3.30 / 3.60 / 3.90 / 4.50 / 4.90 / 5.90 m or customized length

Permissible Modulus [KNm] | 5 |

Permissible Shearing Force Q [KN] | 11 |

Section Modulus Mx[cm3] | 461 |

Geometrical Moment of Inertia Ix [cm4] | 4613 |

Dimension | Values (mm) | Tolerance (mm) |

Beam height | 200 mm | ± 2 mm |

External height | 40 mm | ± 0,6 mm |

External width | 80 mm | + 0,8 mm/-1,2 mm |

Core thickness | 27 mm | ± 0.5 mm |

Standard packaging: 50/100 pcs per package

APAC wholesales highly quality H20 beams. Available in various sizes, the outer parts are made of selected quality solid fir consisting of upper and lower wins and with a three-layer core. The union is designed as a notched and glued joint.

Upon request, they may come in plastic protection to reduce the risk of scratching the outer parts of the H20 beam.

We produce H20 beams just-in-time according to your needs and respect the deadlines of delivery.

From compliance sign-off to pour accuracy and export delivery, APAC H20 beams are built to reduce uncertainty across the full workflow—so you get predictable performance, fewer site corrections, and lower damage risk in transit.

Our H20 timber beams are manufactured in accordance with EN 13377, a European standard that defines how formwork timber beams are classified, what performance requirements they must meet, and how they should be tested. For buyers, this provides a clear technical benchmark for evaluation and documentation, making it easier to align specifications across projects and ensure consistent, predictable performance on site.

Clear reference for checks: EN 13377 gives procurement, engineers, and HSE a defined basis for verification.

Lower mismatch risk: Helps avoid mixing inconsistent grades/suppliers across projects.

Easier standardization: Supports using the same beam spec across multiple sites and subcontractors for smoother execution.

H20 beams are built to carry formwork loads while staying dimensionally stable through repeated use. That stability keeps your formwork straighter, your slab levels more consistent, and reduces the small errors that turn into big rework before a pour.

Rigid beam structure: Solid timber flanges + laminated plywood web provide strong bending performance and reliable geometry.

Less deflection, fewer corrections: Reduced bending/warping helps avoid uneven slab lines and misaligned formwork faces.

More predictable setup: Consistent beam behavior supports repeatable spacing and faster installation with less shimming.

Better finish quality: Straighter formwork contributes to cleaner concrete surfaces and fewer touch-ups after stripping.

Each bundle is packed for safer handling and lower transit damage. We use a pallet base for stable lifting, steel bands to keep the load rigid, and protective film to reduce scratches—so beams arrive cleaner and more site-ready.

Pallet on the bottom: Improves stability and makes forklift loading/unloading faster and safer.

Steel banding: Keeps beams tightly secured, reducing shifting and edge impacts during transport.

Film protection: Helps prevent scratches and scuffs on the wood surface during stacking and handling.

H20 is a double T-section with a height of 20 cm. It is lightweight, and easy to assemble in any formwork. The H20 beam does not crack when nailing and screwing screws.

It can be widely used:

The high degree of flexibility with regard to the geometrical adjustments perfectly suits the superstructure cross-section,

Quality h20 beams accelerated the process of civil construction concreting sections while simultaneously ensuring optimized workloads.

H20 beams are seeing growing demand in the formwork market because they’re adaptable across a wide range of slab, wall, and column forming setups. With strong durability and high load-bearing performance, they’re a practical choice for contractors and rental fleets looking for reliable, repeat-use formwork beams. Below, we answer the most common questions buyers ask when selecting, using, and maintaining H20 beams.

The UV radiation damages wood fibers. With long-term exposure to ultraviolet rays, any kind of wood loses its durability. It becomes vulnerable to cracking and sloughing off.

Since the H20 beams are wooden members, they are also prone to damage with long-term UV exposure. So, these beams are coated with a UV radiation protection layer on the surface. This layer protects the H20 beam from damages due to UV exposure.

Yes, the H20 beams offer a cheap alternative to the traditional formwork systems. The wooden formworks are durable and reusable. So, you can reuse them many times for a long period of time.

You can easily and quickly assemble and dismantle the H20 formwork systems. This will increase your worker’s efficiency in working. Moreover, you can store the H20 beams with easy procedures.

All these features give you the advantage of a good ratio between price and use. So, the H20 beam is a cheap alternative for you.

The load capacity of the H20 beams may vary from the product of one manufacturer to another. But all the H20 beams must conform to some standards. All the manufacturers ensure to always exceed these load characteristics.

The average H20 beams exceed bending resistance capacity compliant to the certificate – DIN1052-1:1988-04. Adhering to this standard, the average H20 beam has a shear strength of ZUL Q = 11.0 kN with an average bending moment of ZUL M = 5.0 kNm.

The average H20 beams exceed the load capacity characteristic limit compliant to the certificate – DIN1052:2008-12 / Eurocode 5. Adhering to this standard, the average H20 beam has a shear strength of Vk = 23.9 kN; an average bending moment of Mk = 10.9 kNm with an average load capacity of Rb,k = 47.8 kN.

APAC always believes that the values of the section modulus and the geometrical moment of inertia apply to new or used concrete formwork H20 beam. And you have to add analogously increased factor of safety needs for severely worm beams.

You have to use a timber beam clamp to connect your H20 beams with posts and barriers. First, connect the beam clamp on the flange section of the H20 beam and secure the connection. For adjustment, you can fit these beam clamps with 40mm and 60mm H20 beams.

If you want to learn how to connect these beam clamps with the H20 beams, you can watch this video.

Figure 5 – H20 Beam Clamp

Figure 5 – H20 Beam Clamp

H20 beams are used in concrete formwork as primary/secondary beams to support slab, wall, and column formwork during pouring and curing.

Most H20 beams use solid timber flanges (top/bottom) and a laminated plywood web (core), bonded with structural adhesives.

Plastic caps suit general site use and protect against moisture/impact at a lower cost. Steel protectors are better for rental fleets or rough handling where end damage is frequent.

Choose based on your formwork layout, span, and handling constraints. Longer beams reduce joints but can be harder to move and store. Many projects use mixed lengths.