keder sheeting

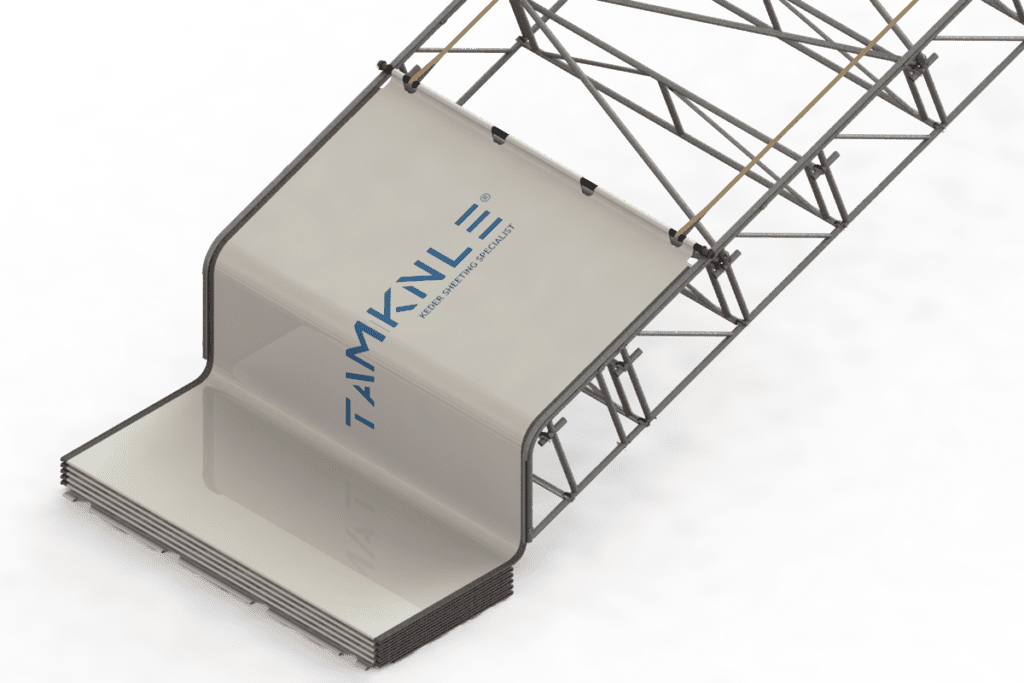

Keder sheeting is a type of PVC-coated fabric roof cover used for temporary roofing and weather protection, especially on modular scaffold roof systems.

It has keder beads (round cords) welded along the sheet edges, which slide into aluminum keder tracks/rails on the roof beams. This creates a secure, tensioned, and water-shedding cover that’s quick to install, allows light through (often translucent), and is commonly supplied with flame-retardant and UV-resistant options.

Your Trusted Manufacturer of Keder Sheeting in China

APAC’s Keder Sheeting is a powerful solution for temporary weather protection. It is ideally suited for a wide range of applications in the residential, commercial, industrial, infrastructure, and events sectors, etc. It is heavy duty and flame retardant, able to withstand different weather and climates over time.

APAC Keder Roof Sheeting conform to BS 7955, flame retardant to EN 13501-1, class B S1, D0, Heavy duty rating for exposed locations and long term installations.

We can manufacture to customer specific dimensions to suit any spacing width and keder diameter, sheets with good light transmission.

Technicial Data:

| Material | PES Polyester, 2 side PVC gloss lacquer, UV stabilised, Anti Mildew |

| Widths | 2.00m,2.07m,2.50m,2.57m,3.00m,3.07m |

| Lengths | 15m,20m,25m,30m,35m,40m,45m (Special length sheets available on request) |

| Colour | Ivory white (standard), other color can be customized. |

| Weight | 650gsm or 850gsm |

| Tensile Strength | 2000N/50mm |

| Tear Resistance | 250N |

| Fire Testing | FR BS 7837 TEST 5438/B2 FR- DIN 4102, B1 – PASS BS EN 13501-1 – Class B, S1, D0 BS476 Part 12 ignition sources C&G – PASS TS62 – BS7955 Annex C.3.1.3 Flammable liquid test (LF) – PASS |

| Gable Sheets | Yes |

Why Choose APAC Keder Sheeting

APAC delivers keder sheeting as a complete temporary roofing supply solution—designed to fit your roof bay, produced with high-frequency welding quality, and packed for export so it arrives ready to install on site.

Built for Temporary Roofing Contractors

We focus on the real jobsite priorities: fit accuracy, fast installation, and predictable performance across changing weather.

- Designed for modular temporary roof systems used across the UK, Canada, and New Zealand

- Translucent sheeting to maintain ambient daylight under cover

- Low-friction keder concept supports quick pull-through installation

Reliable Manufacturing & Consistent Dimensions

APAC controls the key steps that affect water tightness and fit—patterning, cutting, and welding—so each sheet installs smoothly in the keder track.

- CAD-based patterning (AutoCAD or similar) for repeatable sizing

- Laser cutting for consistent edges and dimensions

- Keder beads RF / thermal welded to support watertight performance

Custom Sizes, Faster Replacement, Lower Total Cost

We support standard sizing for routine supply and custom sizing when you need to match specific bay widths or keder diameters—helping reduce site modifications.

- Standard sheets are commonly 5 m in length (as referenced)

- Custom manufacture to suit bay width and keder bead diameters (8/10/12 mm) (as referenced)

- Individual sheet replacement helps reduce downtime and total system cost

Applications of keder sheeting

Keder sheeting is used wherever a project needs fast, reliable temporary weather protection while keeping good daylight and site access. Typical applications include:

Scaffold temporary roofing for refurbishment, re-roofing, and façade works

Bridge and infrastructure maintenance where work must continue in rain/wind

Industrial shutdowns (plants, refineries, power stations) to protect equipment and crews

Construction material storage and protected laydown areas on site

Emergency or temporary buildings and quick-cover shelters

Keder Sheeting | The Ultimate FAQ Guide

Q1 What is Keder?

It can also be called ‘Kador’. Keder allows you to attach the industrial fabric panels to the tent awning or Keder roof structures via the Keder rails/ Quick tracks, as an economical weather protection solution.

The Keder is a continuous strip with single flap or double flap, which consists of two parts: core and Keder fabric.

The core is normally made from extruded PVC, or another elastic material, which is been wrapped in Keder fabric.

On the outside of Keder fabric, there are many exposed fibers, so that the Keder can easily slide into an extrusion with a luff groove – the Keder track.

The other side of Keder fabric is PVC coated, to ensure proper adhesion during welding.

Q2 How does Keder weld with the Keder roof sheeting?

APAC Keder roof sheeting is made of PVC-coated polyester fabric, using the double flap for maximum strength. Because three layers of fabric are welded at the same time, it is generally welded using a radio-frequency welder (RF Welding).

You can see the real welding process in our factory in the below video.

OK, you may hear of radio-frequency welding, but how does it work?

Radio Frequency (RF) welding is a process that uses electromagnetic energy to bond materials. It’s also known as High Frequency (HF) welding. And they don’t require solvents, adhesives, or other additives during the work process.

To give you a better understanding of this process, here is a brief animation.

APAC Keder roof sheeting is manufactured with an emphasis on high performance and quality with safety use at the forefront.

Contact our advisor for more information.

Q3 How to maintain the Keder roof sheeting?

It is quite simple and easy. You just need to consider the three-step process as follow:

(1) Avoid Tears

Before you set up the Keder roof, check for sharp edges on your aluminum track firstly. Avoid direct contact with sharp objects such as screws or utility knives during use.

If the Keder roof sheeting is scratched, you should repair the breakage in time to avoid greater damage, by using the tarpaulin repair tape.

(2) Keep Clean

After use, remember to do a simple cleaning and drying treatment before your storage. That will help you to avoid Keder roof sheeting reproduction breeding bacteria and prevent the decay of the sheet residual chemicals, thus affecting the service life.

(3) Store Properly

Keep Dry–Like any tarpaulin in your inventory, store your Keder roof sheeting dry. This will help you avoid mold.

Keep away from fire – To ensure that the Keder roof sheeting is placed in the appropriate place. Even if you purchase the fire-retardant Keder roof sheeting, you should also be strictly prohibited to fire, to avoid unnecessary losses.

Trust us on this! Keder roof sheeting is durable. It will be the best tarp for your keder roof system.

Q4 Why do APAC use PVC instead of PE as the raw material of keder roof sheeting?

The distinction between PE and PVC is more obvious.

PE keder roof sheeting:

Polyethylene is translucent and easy to process. So, this material is ubiquitous in our articles of daily use.

- It’s odorless and non-toxic, with high resistance to moisture.

- And It can be used normally at -70℃ to -100℃ benefit from the excellent low-temperature resistance and good chemical stability.

- The production of PE keder roof sheeting is akin to PE tarp, it generally uses HDPE ( High-density polyethylene ), which offers such advantages as high rigidity and high chemical resistance. It’s also waterproof.

The PE keder roof sheeting production process:

Mixing & tape extrusion — Weaving PE fabric — Laminating on both sides–automated cutting — welding — Folding, packing & stacking

PE roof sheet is popular among many customers due to its lightweight, affordability and wide range of available colors and sizes.

PE keder roof sheeting is designed for temporary use, and it will not last as long as PVC roof sheet, it’s not suitable for long-term usage in the outside or bad weather environment.

Customers looking for quick short-term use will find our PE roof sheet to be a cost-effective solution.

On the other side, HDPE can cause stress cracking easily with the affection of environment, which limits its application in industry. Because of its wick tear strength, the disadvantage is that it is easy to tear and wear.

It’s hard to imagine the PE keder roof sheeting can not prevent water leaking after being used once or twice. You may suffer a loss or damage caused by the weakness.

PVC keder roof sheeting:

PVC keder roof sheeting is a high-strength polyester fabric coated with polyvinyl chloride (PVC) resin mixing with plasticizers, stabilizers, flame retardants, preservatives and other chemical additives, plasticized at high temperature.

The material, percentage of resin and density are keys in determining whether a PVC sheet performs well.

PVC sheet is based on polyester fabric, coated with enviromentally friendly resin on both sides, one-step forming. The PVC resin fill the gap of fabric, so the PVC keder roof sheeting has excellent property, such as:

- Properties of waterproof, mouldproof, cold resistance, aging resistance, anti-static electricity, etc.

- The elongation at the break, tensile strength and tear strength are better than traditional roof sheets.

- with superfine abrasion performance and anti-skid treatment on surface

- Heat sealing can be used to reduce the joints and eliminate sewing needle holes

- Various bright colours are available according to the needs.

Manufacturing Process:

Polyester Standard Filament Fabric — Impregnated — Drying until firm –Calendering and cooling — Folding, packing & stacking.

The keder roof sheet is made of PVC by coated resulting in an appropriate rain-proof function. It has better weathering quality than the PP and PE roof sheet. The waterproof effect also precedes other water-resistant tarpaulins.

It can be used for long-term outdoor covering, such as waterproof cloth for truck transportation and cargo ship, wind prevention canvas for breeding industry, rain gear for coal-field, and so on.

If you’re looking for the strongest and most long-lasting roof sheets, our PVC keder roof sheeting will be the right choice for you.

the reasons why we use PVC instead of PE to manufacture keder roof sheeting are multifarious. Overall,

- The waterproof ability of PVC is better than PE.

- PVC keder roof sheeting is more hard-wearing.

- PVC sheeting is propitious to outdoor work.

- PVC keder roof sheet has much better ageing resistance than PE sheet.

No matter the size of your project, we’ve got you covered.

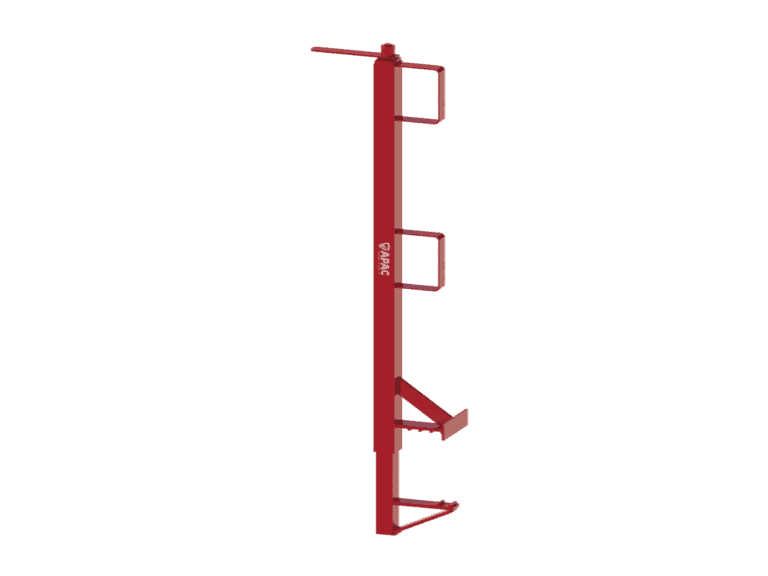

Q5 How To Install Keder Roof Sheeting For Keder Temporary Roofs?

The PVC tarpaulin is ideal for temporary roof coverings in keder roofs. The manufacturers will offer you PVC tarpaulins with widths that can fit the keder roof bay width of the scaffold. These rolls come with a variable-sized keder bead attached at the edges of the tarpaulin throughout the length so that you can easily install it on keder systems.

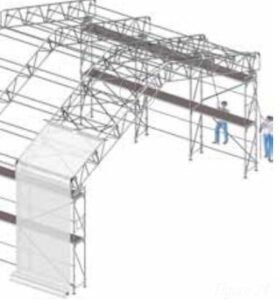

Follow these steps to install a PVC tarpaulin for keder temporary roofs:

- Make sure that the keder roof is correctly assembled and ready for the roof covering installation.

- Choose a tarpaulin that can fit with the roof bay width of the scaffold. Since all the roof bays have similar widths, choose several PVC tarpaulins to cover the whole roof area.

- You have to proceed by installing tarpaulins on each single truss bay individually. Start from any one side. Position the tarpaulin in front of the truss bay you have chosen.

- There is a hollow pocket at the end side of the roof sheet to insert a tube for pulling the sheet. Insert a tube through this pocket. Fasten a rope on two sides of this tube leaving some sagging in the center. Fasten another rope at the center of the previous rope. So, when you pull the second rope, the attached ends of the first rope will pull the tube at two points.

- Lay the long rope over the roof. You need to place the roof covering at the keder grooves and insert it.

- Pull the rope from the other side. Try to pull the rope evenly to prevent skewing. Also, make sure that the edges of the tarpaulin remain straight as you are pulling the rope.

- When the first end of the PVC tarpaulin reaches the other side, stop pulling, keeping a 15 cm to 20 cm extended portion. Make a fold with the extended portion around the frame rails at the opposite end.

- Now you need to secure the PVC tarpaulin with the rails. Use rail locking pins to sucre it. It is recommended that you use three pins at the edges and single locking pins in between the two edges, following a fixed interval.

- Follow the same steps to install the other tarpaulins until you cover the entire roof.

The PVC tarpaulin is ideal for temporary roof coverings in keder roofs. The manufacturers will offer you PVC tarpaulins with widths that can fit the keder roof bay width of the scaffold. These rolls come with a variable-sized keder bead attached at the edges of the tarpaulin throughout the length so that you can easily install it on keder systems.

Follow these steps to install a PVC tarpaulin for keder temporary roofs:

Make sure that the keder roof is correctly assembled and ready for the roof covering installation.

Choose a tarpaulin that can fit with the roof bay width of the scaffold. Since all the roof bays have similar widths, choose several PVC tarpaulins to cover the whole roof area.

You have to proceed by installing tarpaulins on each single truss bay individually. Start from any one side. Position the tarpaulin in front of the truss bay you have chosen.

There is a hollow pocket at the end side of the roof sheet to insert a tube for pulling the sheet. Insert a tube through this pocket. Fasten a rope on two sides of this tube leaving some sagging in the center. Fasten another rope at the center of the previous rope. So, when you pull the second rope, the attached ends of the first rope will pull the tube at two points.

Lay the long rope over the roof. You need to place the roof covering at the keder grooves and insert it.

Pull the rope from the other side. Try to pull the rope evenly to prevent skewing. Also, make sure that the edges of the tarpaulin remain straight as you are pulling the rope.

When the first end of the PVC tarpaulin reaches the other side, stop pulling, keeping a 15 cm to 20 cm extended portion. Make a fold with the extended portion around the frame rails at the opposite end.

Now you need to secure the PVC tarpaulin with the rails. Use rail locking pins to sucre it. It is recommended that you use three pins at the edges and single locking pins in between the two edges, following a fixed interval.

Follow the same steps to install the other tarpaulins until you cover the entire roof.