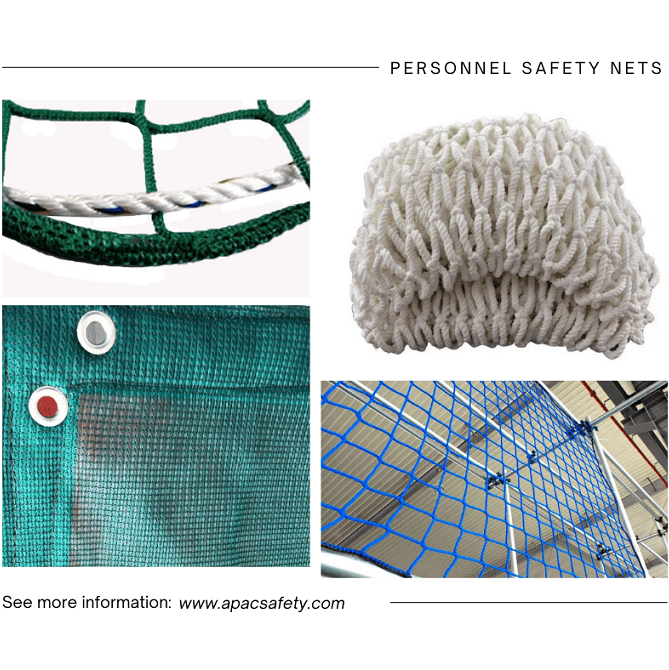

personnel safety nets

- Meet or exceed ANSI and OSHA 1926.105 requirements.

- Meets customization needs: optional reinforcement ribs or multi-layer liners, with customizable lengths and sizes.

- Extensive export experience with a dedicated order-tracking process, delivering full end-to-end visibility: production → inspection → packing → shipment documentation updates.

what is personnel safety net

A personnel safety net is a passive fall-protection net installed below or alongside a work area to catch a worker if they fall, reducing the chance of serious injury and preventing contact with the level below. It’s commonly used on high-risk edges, openings, bridges, and structures where guardrails or harness systems are impractical for the work sequence, and it can be paired with an optional debris liner to help stop tools or materials from falling through the mesh.

types of personnel safety nets for you

Different projects call for different net types depending on the work-at-height zone, the debris risk, and how you plan to install and move protection as the job progresses. Below are the most common types of personnel safety nets we supply—so you can match the right net configuration to your structure, workflow, and compliance requirements.

construction personnel safety nets

- Material: nylon

- Weight: 4-8 kg/piece

- Using life: 3-5 years

reinforced edge personnel safety nets

- UV : 3 % as your request.

- Denier: 200D~550D

- Material: 100% New HDPE

knotless personnel safety nets

- Material: PE /Polyester /Nylon

- Mesh Size: 4cm / 5cm / 6cm / 8cm / 10cm / 12cm / 15cm / 20cm

- Color: Colorful

heavy-duty personnel safety nets

- Type: double deck

- UV rate: 3%

- Knitted eyeholes along both edges and through the center

Why Choose APAC personnel safety net

APAC personnel safety nets add an extra layer of passive protection to your working-at-height plan—helping reduce exposure to edge hazards and falling debris, while still keeping the work area bright and workable. Designed to complement true edge protection (guardrails/edge protection systems), our nets support safer, more controlled work zones on dynamic sites.

Compliance-Ready Safety Nets

Built to meet the expectations of modern projects, with clear compliance references for approvals and site documentation.

Complies with ANSI requirements for personnel safety nets

Complies with OSHA requirements for safety & fall protection systems

Supports safer work-at-height operations where edge/debris exposure is present

Printed Safety Netting for Clear Site Identity

Need your netting to do more than “just protect”? We offer printed safety netting—useful for site identification, contractor branding, and clearer perimeter communication (as demonstrated in the printed safety net video).

Printed netting option for branding/visibility

Helps keep site boundaries recognizable across phases and multiple subcontractors

Supports distributor programs with consistent presentation on repeat orders

High-Tenacity Nylon Built for Fall Protection

Engineered with high tenacity 3.5″ knotted nylon and tested to meet strict construction fall protection requirements.

High-strength nylon net construction for personnel protection

Designed for demanding, repeat-use jobsite conditions

Performance-focused design for safety-critical applications

Trusted by contractors worldwide

Applications of personnel safety nets

Personnel safety nets are used to create a passive “catch zone” anywhere crews work at height and edges/openings change with the workflow.

Vertical building construction (slab edges, floor openings)

Elevator shafts and temporary openings

Bridge construction and maintenance

Industrial plants, refineries, offshore platforms

Marine ship repair and marine construction

Tunnels and highway overpass works

personnel safety nets | The Ultimate FAQ Guide

Q1: What is a personnel safety net used for?

It provides passive fall protection by catching a worker in the event of an accidental fall, and it can also help reduce dropped-object risk when used with a debris liner.

Q2: Do you offer debris liners?

Yes. Nets can be supplied with or without a debris net liner, with liner options suitable for small debris or chunk debris depending on your site risk.

Q3: What standards do these nets comply with?

The system is stated to comply with ANSI A10.11 and OSHA safety net requirements for fall protection applications.

Q4: How are the nets attached on site?

Perimeter steel snap hooks/clips are installed around the edges (commonly 4 ft / 48 in spacing, staggered) for secure rigging and easier net-to-net connection.

Q5: Do you have stock sizes, or can you make custom sizes?

Both stock sizes and custom sizes are available to fit different deck layouts, shafts, and spans.

Q6: Can nets be connected together for large coverage areas?

Yes. The staggered hook layout is designed to make it easier to connect multiple nets side-by-side for wider coverage.