lvl timber plank

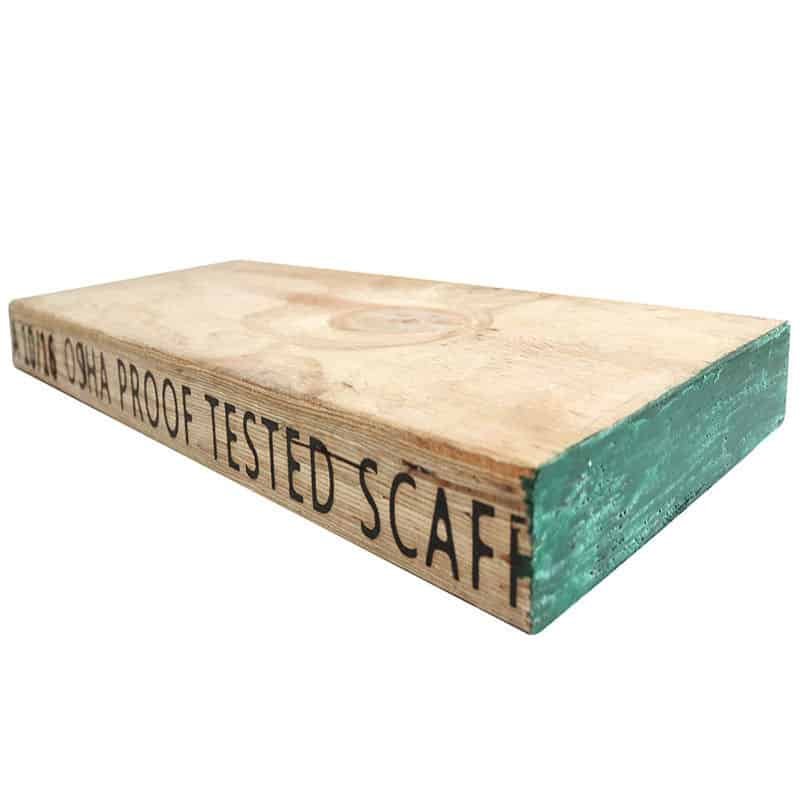

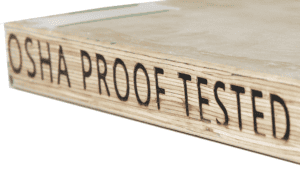

- Tested and certified to meet OSHA and ANSI safety requirements.

- Automated production + strict QC for repeatable batches—better for multi-project supply.

- Made with A-grade WBP phenolic glue, boiled at 100°C for 72 hours with no delamination—built for harsh site exposure.

- 10% lighter than solid wood, lower handling cost, faster install/dismantle, higher daily productivity for crews and rental turnarounds.

what is lvl timber plank

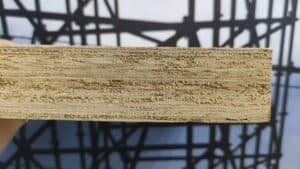

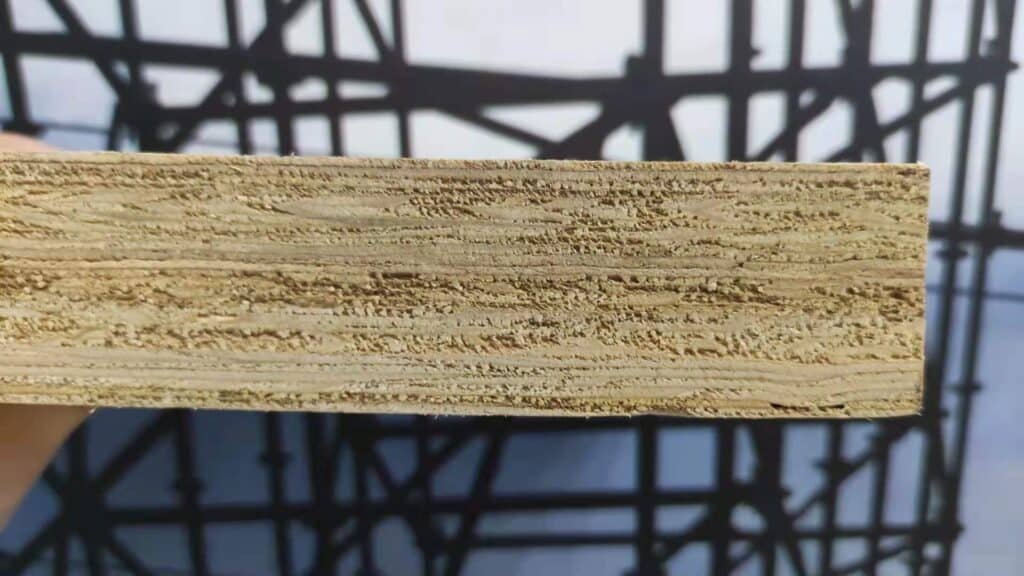

LVL stands for Laminated Veneer Lumber, which is a type of engineered wood product that is commonly used in construction projects. LVL timber planks are made by bonding thin layers of wood veneers together using adhesive, resulting in a strong and durable product that is ideal for use in structural applications. Engineering professionals, architects, and builders all hold these boards in high respect due to their capacity to carry heavy loads.

different types of lvl timber plank available

APAC offers a range of LVL (Laminated Veneer Lumber) timber planks designed specifically for scaffolding systems, offering superior strength, durability, and cost-efficiency for both temporary and permanent scaffold structures.

These LVL timber planks are engineered to meet the demanding needs of scaffolding systems, offering reliable load-bearing capacity and long-lasting performance, ensuring safety and stability across a wide range of construction environments.

lvl timber planks without painting

High-strength timber planks that are perfect for scaffolding platforms, providing reliable support and stability for heavy-duty construction projects.

lvl timber planks with painting

Finished with a protective coating, these planks are designed to withstand harsh environments and general wear, making them ideal for long-term scaffolding use.

lvl timber planks with steel end

Reinforced with steel end caps, these planks provide additional durability and impact resistance, making them suitable for high-traffic areas and heavy-duty scaffolding applications.

More details about lvl timber planks

Materials: poplar/hardwood/pine or as request

Glue:

Melamine WBP Glue, Phenolic WBP Glue

Moisture content: 8%~12%

Density: 580-620kgs/cbm

Standard: OSHA, ANSI

Popular sizes:

38x225x3900mm/6000mm

40x235x3900mm/6000mm

42x230x3900mm/6000mm

length can be up to 12000mm

Packing: standard export packing in pallets

Cutting-edge technology and premium-grade materials are used in the production of APAC LVL Timber Planks. We provide affordable costs as a direct factory source without sacrificing quality. To guarantee prompt delivery, we have a sizable inventory, and our customer service staff is on hand around the clock to help with any questions or concerns.

Why choose apac lvl timber plank

APAC LVL timber planks are engineered to provide superior strength, durability, and cost-efficiency for scaffolding systems, ensuring a reliable and safe working environment on construction sites.

Engineered for Strength and Stability

Our LVL timber planks are manufactured using high-quality laminated wood layers to create a material that is stronger and more stable than traditional solid wood, with a higher load-bearing capacity. This makes them ideal for scaffolding platforms that need to support heavy equipment and workers.

- High strength-to-weight ratio

- Consistent dimensions with minimal warping

- Reliable load-bearing capacity for scaffolding systems

Customizable to Your Needs

APAC offers custom sizes for LVL timber planks, ensuring a perfect fit for your specific scaffolding requirements. Whether you need planks for a small residential project or a large industrial site, we can tailor the dimensions to your needs, ensuring optimum performance and safety.

- Custom lengths and dimensions to fit specific projects

- Tailored solutions for scaffolding configurations

Long-Lasting Performance

Designed to withstand the rigors of construction, APAC’s LVL planks are resistant to warping and twisting, ensuring long-term performance even under heavy use. With optional protective coatings, our planks are also more weather-resistant than traditional timber, reducing maintenance costs and extending their lifespan.

- Weather-resistant and moisture-resistant options

- Suitable for long-term use in harsh construction environments

Trusted by contractors worldwide

Applications

LVL timber planks have a wide range of applications in the construction industry, from structural support to decorative features and industrial uses. Their strength, durability, and versatility make them an ideal choice for many different types of building projects.

Contact us right now with orders, questions, or quotes. Allow us to assist you in locating the ideal LVL timber planks for your upcoming undertaking.

lvl timber planks | The Ultimate FAQ Guide

1. What does LVL timber mean?

LVL (Laminated Veneer Lumber) is an engineered wood product made by bonding thin layers of wood veneers together with adhesives. This process creates a strong, durable, and dimensionally stable material that is ideal for structural applications like scaffolding planks. LVL timber is known for its high strength-to-weight ratio and resistance to warping.

2. What is the best wood for scaffold planks?

The best wood for scaffold planks is typically hardwood or softwood that is strong, durable, and resistant to wear. Common choices include Douglas Fir, Pine, and Spruce. LVL timber is also an excellent choice for scaffold planks due to its engineered strength, consistency, and high load-bearing capacity, making it a reliable option for both temporary and permanent scaffolding systems.

3. What are the disadvantages of LVL timber?

While LVL timber is strong and stable, there are a few disadvantages:

Moisture sensitivity: If not properly sealed or treated, LVL timber can absorb moisture and lose strength in wet conditions.

Cost: LVL timber is often more expensive than traditional solid wood planks due to the manufacturing process.

Limited flexibility: Unlike solid wood, LVL timber is engineered for specific applications and is less flexible in terms of customization after manufacture.

4. How thick should a scaffold plank be?

The thickness of scaffold planks typically ranges from 38mm (1.5 inches) to 50mm (2 inches), depending on the load-bearing requirements of the scaffold and local regulations. The specific thickness required is determined by the height, intended load, and span between supports.

5. How do you secure scaffold planks?

Scaffold planks are secured using cleats, scaffold clips, or brackets that attach the planks to the scaffold frame or support structure. The planks should be securely fastened to prevent shifting and ensure safety during use. In addition, scaffold ties or pins may be used to lock the planks in place, especially in areas of high wind or heavy load conditions. Always ensure that the planks are properly positioned and secured according to local safety regulations.