In the construction industry, the number of fatal and nonfatal occupational injuries is higher than in other industries. Among the causes of these accidents, falls from the leading edge can be the most hazardous activity.

The aim of the Edge Protection System (EPS) is to reduce the risk of falling from leading edge, leading to the advancement and promotion of safety in the construction industry.

In this blog, I want to share more info on EPS with you, including the standard in design and details of the EPS, field applications of these systems, and recommendations for further development and standardization of the EPS in my opinion.

▶ What is EPS (edge protection System)?

Edge protection comes in very many different forms, it really comes into its own when there’s any need to protect people from falling from a leading edge.

The edge protection system comes into the picture during all sorts of under-construction buildings, obviously in large-scale commercial buildings, in civil engineering infrastructure worksites, residential buildings, portal frame buildings commonly used in warehousing and so on, flat roof renovation, and also it covers protecting people from falling from vehicles loading and unloading, and also from falling into excavations and other deep holes.

Normally the EPS doesn’t include scaffolds as the standards for scaffolds and the way of applying scaffolds are very different.

▶ How does the Edge Protection System work?

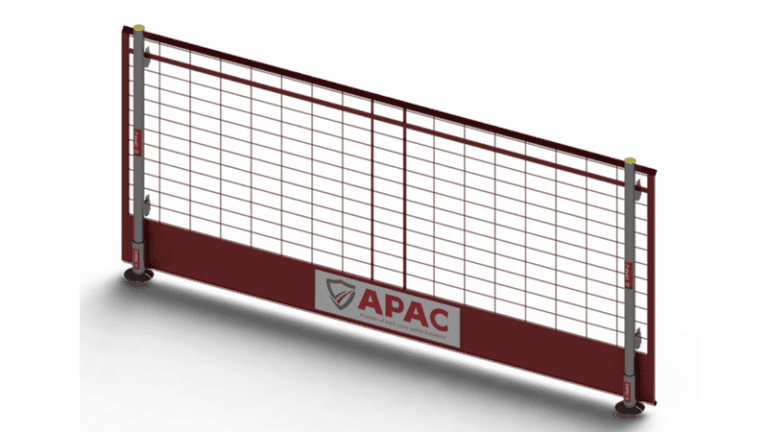

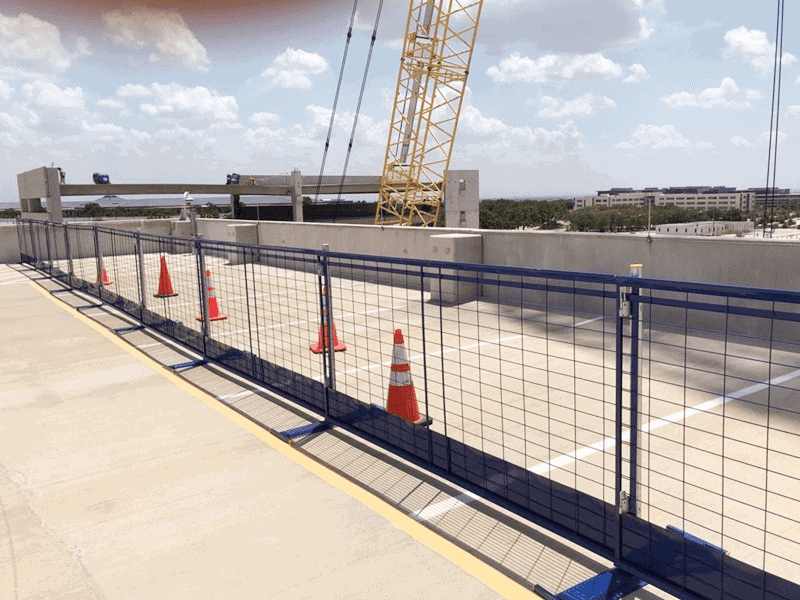

Obviously, the point for most edge protection systems is the mesh panels, you can see a selection here from the different manufacturers, they are very different in detail, but they have similar features. They use a wire mesh as debris protection, they have a toe board and of course, they’re stiff enough to provide the handrail protection.

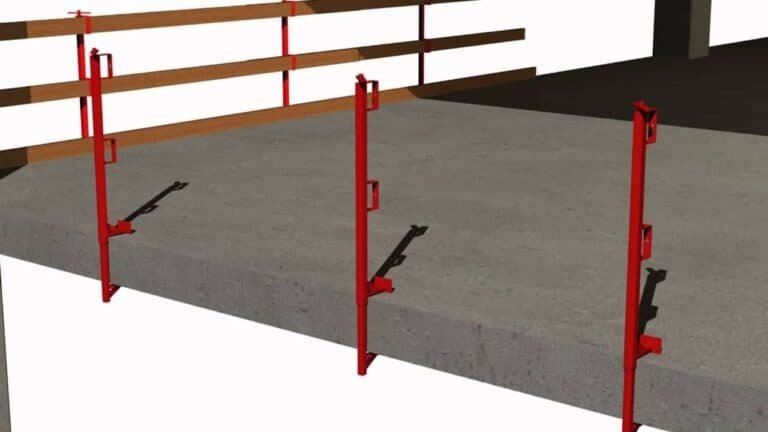

There are many different ways of fixing edge protection mesh panels to a structure under construction, the basic method relies upon a post, and then a means of fixing that post to the structure.

On the small diagrams below, the typical mounting of a post onto a concrete slab through a bolted foot is on the left-hand side, on the right-hand side, you see a flexibly adaptable cantilever fixing bolted to a steel perimeter being at the edge of a steel frame building.

so say apart from the obvious mountings on slabs and so on, they also can be mounted to precast concrete to formwork beams, sheet piles, bridge parapets and structural timber elements.

There are plenty of envelopes in hand to reduce the exposure to work at height risks, obviously what the edge protection system needs to do is fit to the precast element or to the steel beam before it’s lifted into place.

▶ What is the classification of different Edge Protection Systems?

BS EN 1 3374 specifies three classes of edge protection: Class A, Class B and Class C.

Class A

Class A is designed to look at applications on flat roofs and slabs, and may be used if the angle is less than 10 degrees. Such edge protection systems are designed to withstand only static loads, and 470 mm which is supposed to pass through the edge protection guardrails is the maximum separation between the horizontal elements. So this is very similar to the scaffolding rules.

Class B

Class B covers those applications where we have we’re protecting much more steeply inclined roofs or surfaces, may be used if the angle is less than 30 degrees without limitation of the falling height, or 60 degrees and the falling height is less than 2m.

Taking account of the protection effect, the standard stipulates that objects larger than 250 mm mustn’t pass through the protection.

Class C

And now the final class is class C steeply inclined surfaces, in order to protect against smaller items, so a sphere of 100 mm diameter mustn’t pass through the protection.

Class C may be used if the angle is between 30 and 45 degrees without limitation of the falling height, or 45 and 60 degrees and the falling height is less than 5m.

For the most part, Class C is provided by soft netting, and the reason here is that items roll down the roof can generate high dynamic forces, to absorb the energy, we need to use a soft net rather than the wire mesh panel, for example, the safety net fans.

The illustration here shows a typical safety net fans system from APAC.

▶ Are there any other forms of Edge Protection System?

There’s a lot of development going on with edge protection systems, which we’ve seen recently as demand for much more applications.

As the rooftop edge protection, the freestanding systems act through a lever arm with the counterweight. Here are shown just with simple guardrails, but it can provide similar setups with mesh panels also.

The normal standard protection is up to one meter, but some clients and then use as a demanding protection right from the floor of the slab up to the soffit, here you see a typical example of full height solution.

The way that this is being handled is by compression posts, with mesh panels fitted on it one by the other, floor to the soffit.

These compression posts are secured purely by friction, by developing a compressive force in the post by different mechanical means and using that to effectively jam the posts between the floor and the soffit. Obviously, the friction fitting also allows us to remove the need for bolt into the slab, and can potentially provide a very quick and easy way of rigging a post.

And there are attachments available to fit most of the aluminum timber formwork beams that are in use.

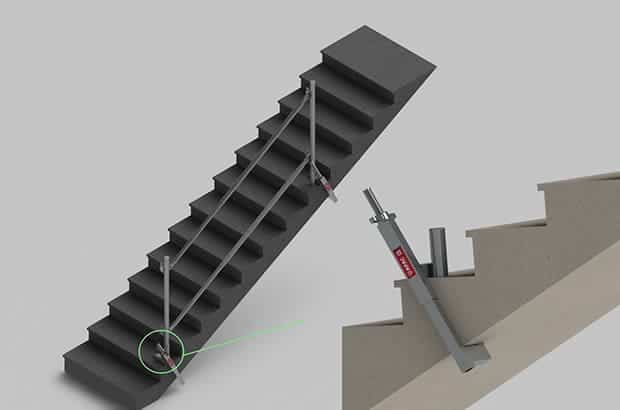

The innovative solutions for staircases, both for precast and steel fabricated stairs, so there’s no need to go on using traditional methods with scaffold fitting or whatever taking up a lot of time and effort and labor time in purpose in custom making solutions for staircases.

Of course, barriers can also be mounted a ground level, they have feet support feed available which enables you to fix your barriers as demarcation fences at ground level, extending the use of the mesh barriers, reducing the overall costs.

Some companies in the formwork industry have developed climbing protection screens or windscreens which rise up a high-level building with their formwork for debris protection.

▶ What has become a bottleneck that restricts the development of the Edge Protection System?

With the innovation of the edge protection industry, there are still have a few issues.

The EPF(edge protection Federation), as the earliest forum for discussion among industry peers to set standards and training schemes to give safety advice and guidance. The federation only involves those leading companies in the UK until now.

But there are still many companies manufacturing and supplying edge protection worldwide, that do not get involved in EPF early enough. Do they have the chance to join the federation to promote the edge protection system used globally, saving more lives?

For providing the best application or the best solution, some new items are manufactured to meet users’ needs. Is there an effective regulatory approach to installation training and usage?

With the efforts of our peers, we believe that newer and more comprehensive industry standards will emerge in the near future.

As the leading edge protection system manufacturer and supplier in China, APAC will continue to do so going forward by focusing on our core values — to prevent occupational injuries for more worksite.

I am Pieter, the managing director of APAC. I invite more people to move the construction industry forward.

Please don’t hesitate to contact me with your thoughts, questions, and comments.